Recovery and recycling process for positive electrode material of waste ternary lithium battery

A ternary lithium battery and positive electrode material technology, which is applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of the environmental impact of the use of extractants, high cost consumption, etc., to avoid the use of extractants, simplify Recycling steps, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

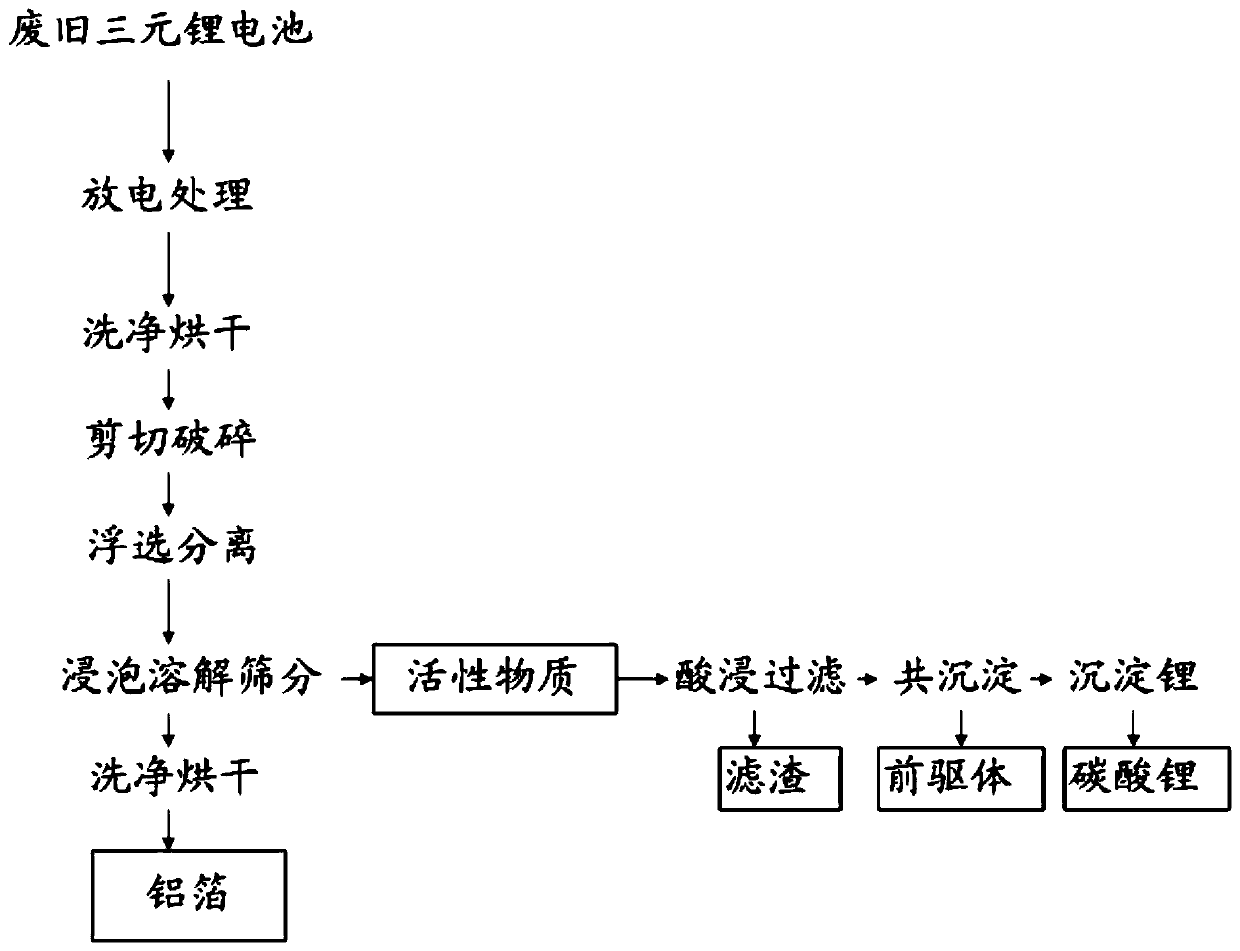

Image

Examples

Embodiment 1

[0050] 1. Soak the waste ternary lithium battery NCM532 in saturated salt water for 12 hours;

[0051] 2. Wash the discharged waste ternary lithium battery NCM532 repeatedly with clean water several times and dry it;

[0052] 3. Cut and break the dried battery into battery slices with a diameter of 1 cm;

[0053] 4. Separation of pole piece, shell and diaphragm by flotation method;

[0054] 5. Soak the positive electrode piece in a solvent that is uniformly mixed with choline chloride and butanediol. The molar ratio of choline chloride and butanediol is 2:1, and the heating temperature is 160°C. Soak and stir for 5 hours. Liquid mass volume ratio (g:ml) is 1:20;

[0055] 6. After soaking and filtering, the filter residue is screened to separate the larger aluminum foil from the active substance;

[0056] 7. Use the active substance with H 2 SO 4 for soaking, H 2 SO 4 The concentration is 2.5mol / L, and the reducing agent is H 2 o 2 , add 2mlH per gram of active substan...

Embodiment 2

[0060] 1. Soak the waste ternary lithium battery NCM532 in saturated salt water for 12 hours;

[0061] 2. Wash the discharged waste ternary lithium battery NCM532 repeatedly with clean water several times and dry it;

[0062] 3. Cut and break the dried battery into battery slices with a diameter of 1 cm;

[0063] 4. Separation of pole piece, shell and diaphragm by flotation method;

[0064] 5. Soak the positive electrode sheet in a solvent that is uniformly mixed with choline chloride and butanediol. The molar ratio of choline chloride and butanediol is 2:1, and the heating temperature is 170°C. Soak and stir for 5 hours. Liquid mass volume ratio (g:ml) is 1:20;

[0065] 6. After soaking and filtering, the filter residue is screened to separate the larger aluminum foil from the active substance;

[0066] 7. Use the active substance with H 2 SO 4 for soaking, H 2 SO 4 The concentration is 2.5mol / L, and the reducing agent is H 2 o 2 , add 2ml H per gram of active substa...

Embodiment 3

[0070] 1. Soak the waste ternary lithium battery NCM532 in saturated salt water for 12 hours;

[0071] 2. Wash the discharged waste ternary lithium battery NCM532 repeatedly with clean water several times and dry it;

[0072] 3. Cut and break the dried battery into battery slices with a diameter of 1 cm;

[0073] 4. Separation of pole piece, shell and diaphragm by flotation method;

[0074] 5. Soak the positive electrode sheet in a solvent that is uniformly mixed with choline chloride and butanediol. The molar ratio of choline chloride and butanediol is 2:1, and the heating temperature is 180°C. Soak and stir for 5 hours. Liquid mass volume ratio (g:ml) is 1:20;

[0075] 6. After soaking and filtering, the filter residue is screened to separate the larger aluminum foil from the active substance;

[0076] 7. Use the active substance with H 2 SO 4 for soaking, H 2 SO 4 The concentration is 2.5mol / L, and the reducing agent is H 2 o 2 , add 2ml H per gram of active substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com