Preparation method for Fe and Cu bi-metal loading mesoporous carbon and alumina composite ceramic membrane material, and application of ceramic membrane material

A composite ceramic membrane and alumina carbon oxide technology, which is applied in chemical instruments and methods, special compound water treatment, oxidized water/sewage treatment, etc., can solve the problems of cumbersome operation and waste of catalyst, and achieve simplified recovery steps and improved degradation effect , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

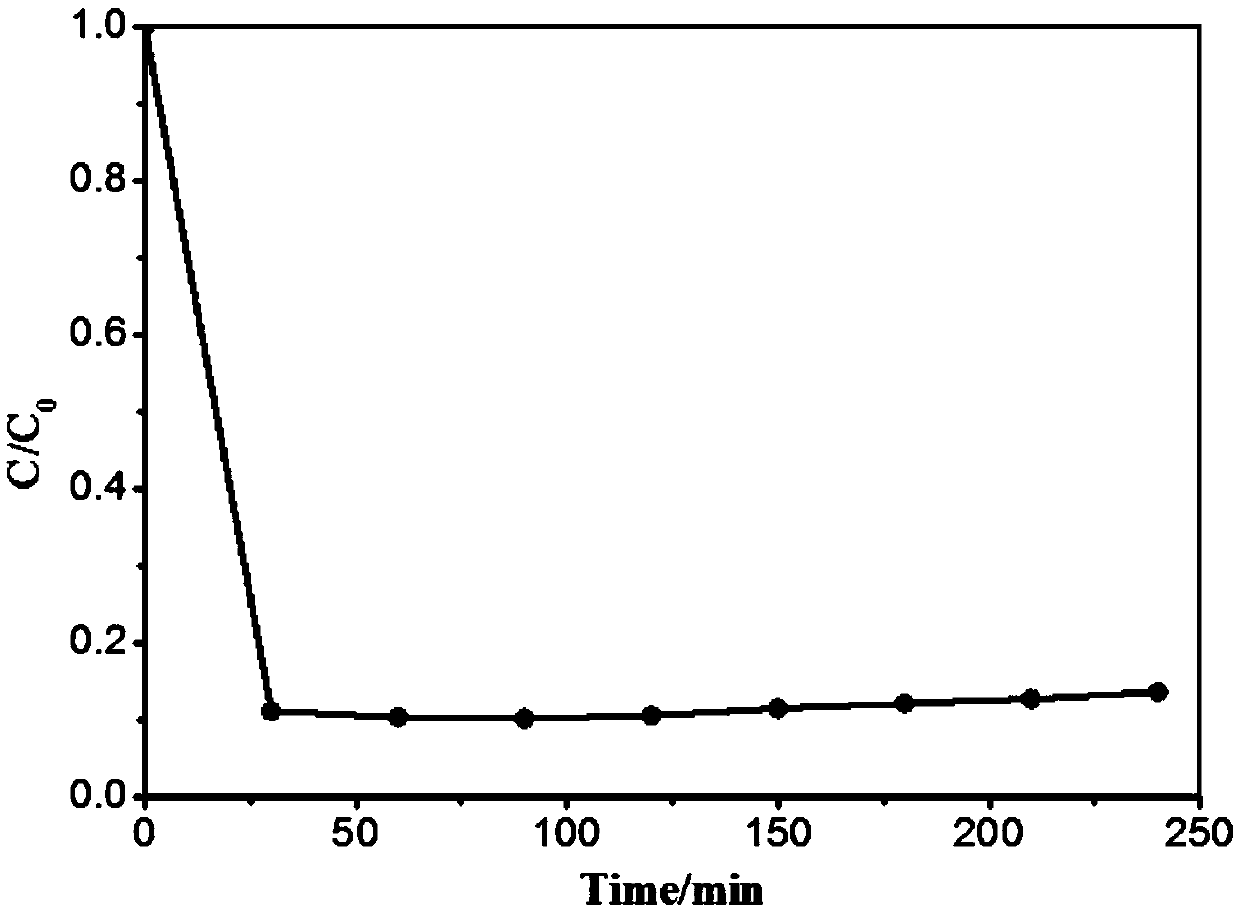

[0024] In this example, a mesoporous carbon hollow alumina ceramic membrane with an iron-copper bimetal loading rate of 3wt% is used. At pH=3, Fe:H 2 o 2 =1:10 (molar ratio) to treat ofloxacin wastewater.

[0025] (1) Pretreatment of the carrier: Cut the alumina hollow ceramic tube carrier into small sections with a length of 6 cm according to the height of the reactor (the height of the reactor ≥ 6 cm), put it in deionized water and ultrasonically clean the carrier surface for 5 minutes, and put it into Dry in an oven at 60°C for 4 hours.

[0026] (2) Synthesis of iron-copper mesoporous carbon material: 0.139g Fe(NO 3 ) 3 9H 2 O and 0.041g Cu(NO 3 ) 2 ·3H 2 O was dissolved in absolute ethanol to make Fe:Cu=2:1 (molar ratio), heated to 45°C in a water bath, and added dropwise the ethanol solution of 6g of mesoporous carbon precursor (F127 6wt%, phenolic resin 30wt%, the rest is ethanol solvent), vigorously stirred for 30min; poured into a watch glass, evaporated at roo...

Embodiment 2

[0030]This example adopts the mesoporous alumina carbon oxide ceramic film with the iron-copper bimetal loading ratio of 4wt%, at pH=5, Fe:H 2 o 2 =1:20 (molar ratio) to treat ofloxacin wastewater.

[0031] (1) Pretreatment of the carrier: Cut the alumina hollow ceramic tube carrier into small sections with a length of 6 cm according to the height of the reactor (the height of the reactor ≥ 6 cm), put it in deionized water and ultrasonically clean the carrier surface for 8 minutes, and put it in Dry in an oven at 70°C for 5 hours for later use.

[0032] (2) Synthesis of iron-copper mesoporous carbon materials: the bimetallic loading rate was added to the ethanol solution of the mesoporous carbon precursor 4wt% 0.186g Fe(NO 3 ) 3 9H 2 O and 0.054g Cu(NO 3 ) 2 ·3H 2 O was dissolved in absolute ethanol to make Fe:Cu=2:1 (molar ratio), heated to 47°C in a water bath, and the ethanol solution of 6g of mesoporous carbon precursor was added dropwise (F127 6wt%, phenolic resin ...

Embodiment 3

[0036] This example adopts the mesoporous alumina carbon oxide ceramic membrane with the iron-copper bimetal loading ratio of 5wt%, at pH=11, Fe:H 2 o 2 =1:30 (molar ratio) to treat ofloxacin wastewater.

[0037] (1) Pretreatment of the carrier: Cut the alumina hollow ceramic tube carrier into small sections with a length of 6 cm according to the height of the reactor (the height of the reactor ≥ 6 cm), put it in deionized water and ultrasonically clean the carrier surface for 10 minutes, and put it in Dry in an oven at 80°C for 6 hours for later use.

[0038] (2) Synthesis of iron-copper mesoporous carbon material: the bimetallic loading rate is added to the ethanol solution of the mesoporous carbon precursor 5wt% 0.232g Fe(NO 3 ) 3 9H 2 O and 0.068g Cu(NO 3 ) 2 ·3H 2 O was dissolved in absolute ethanol to make Fe:Cu=2:1 (molar ratio), heated to 50°C in a water bath, and added dropwise the ethanol solution of 6g of mesoporous carbon precursor (F127 6wt%, phenolic resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com