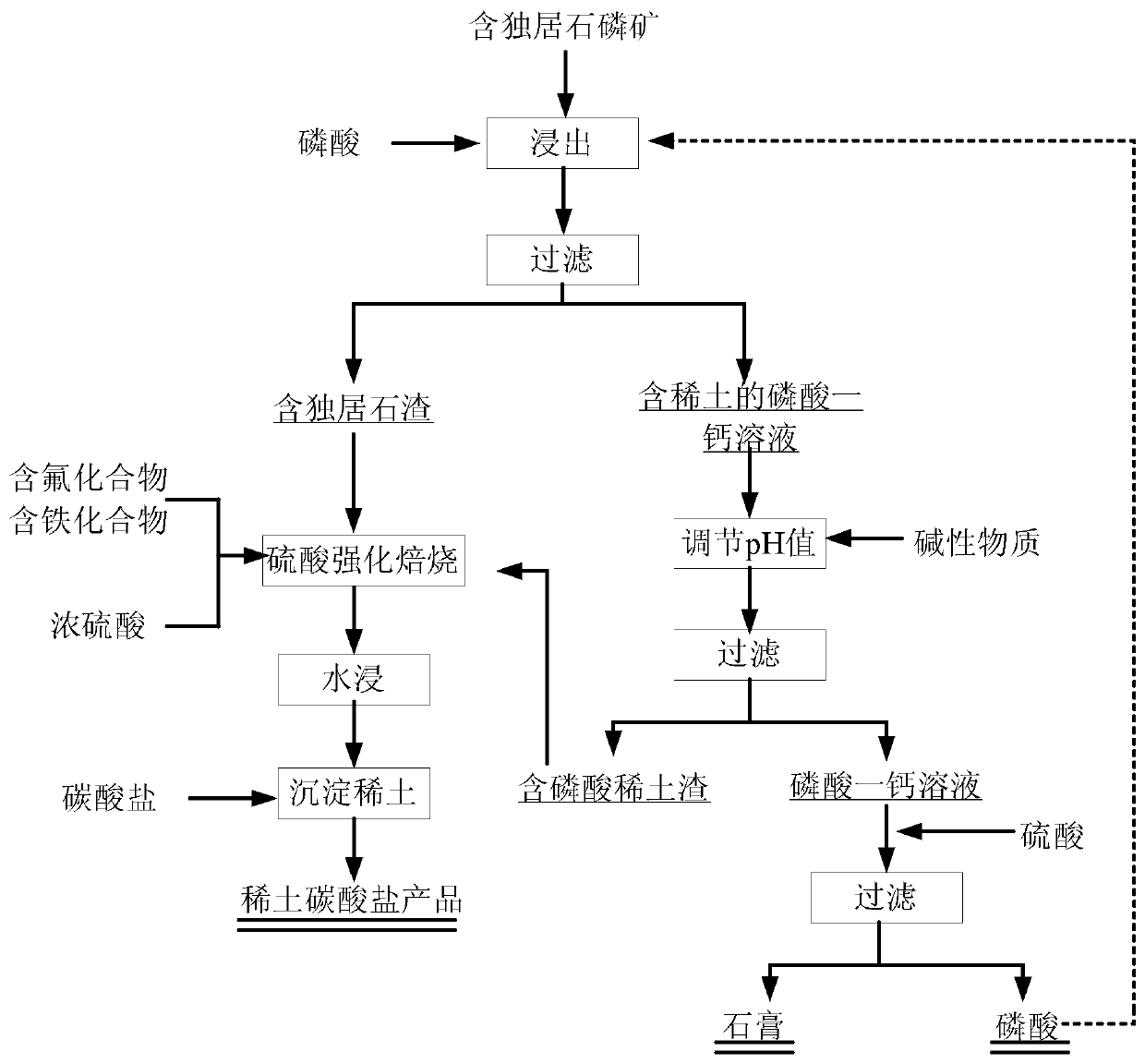

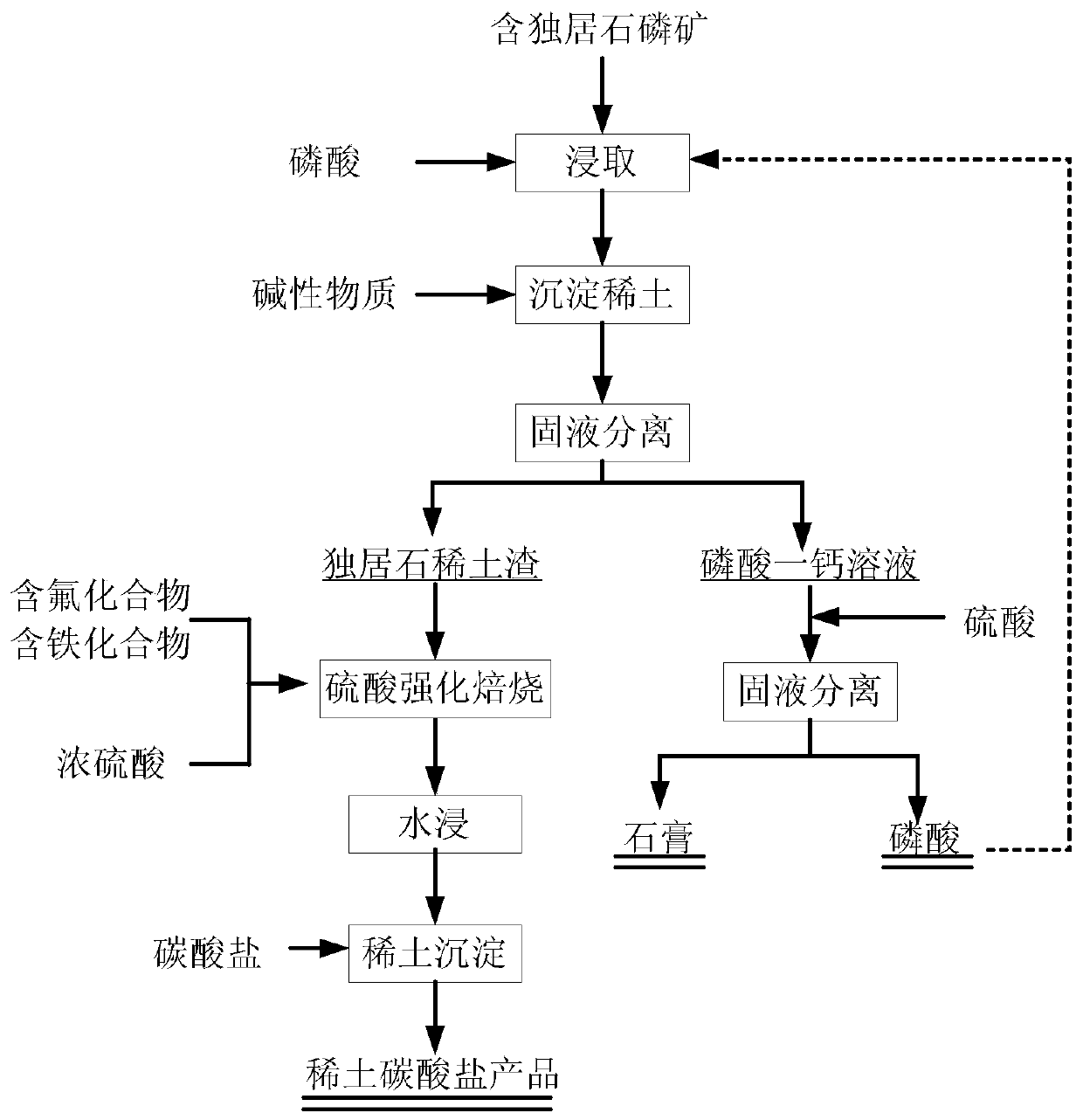

Method for Comprehensive Recovery of Phosphorus and Rare Earth from Monazite-containing Rare Earth Phosphate Rock

A monazite and rare earth technology, which is applied in the field of comprehensive recovery of phosphorus and rare earths, can solve the problems of failure to achieve effective recycling, inability to completely decompose monazite, and difficulty in effective sorting of ores, so as to achieve low-cost comprehensive recovery of rare earths and improve Rare earth recovery rate and the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0054] With 50g containing monazite 23.6%, the phosphate rock that the total amount of rare earth is 15.5% is raw material, and adopting mass concentration is 15% (in terms of P 2 o 5 Control the liquid-solid ratio of the system at 2:1, add 100mL of phosphoric acid solution, react at 55°C for 8 hours, and obtain 124mL of rare earth-containing monocalcium phosphate solution and 12g of monazite slag after filtration.

[0055] Add sodium carbonate to the solution containing monocalcium phosphate, adjust the pH of the solution to 0.5, and precipitate the rare earth in the solution, and obtain 130 mL of monocalcium phosphate solution and 5.5 g of phosphate-containing rare earth slag after filtration. After adjusting the pH value, the content of calcium ions in the dicalcium phosphate formed in the system accounts for 1.3% of the total content of calcium ions in the system.

[0056] Add sulfuric acid to the obtained monocalcium phosphate solution to remove calcium, and separate sol...

Embodiment 1-2

[0060] The preparation process is the same as that of Example 1-1, the difference is that, after adding phosphoric acid for leaching, instead of filtering, sodium carbonate is directly added to precipitate the rare earth in the solution, and a mixture of phosphate-containing rare earth slag and monazite-containing slag is obtained. scum. in:

[0061] The weight of the obtained mixed slag is 17.7g, which accounts for 35.4% of the weight of the phosphate rock raw material.

[0062] The amount of rare earth contained in the monocalcium phosphate solution obtained through testing and calculation is 0.37g; except for the rare earth contained in the monocalcium phosphate solution, other rare earths all enter the obtained mixed slag. At this time, the obtained rare earth amount is 7.38g , which is 95.2% of the total rare earth content in the phosphate rock raw material.

Embodiment 2-1

[0064] With 50g containing monazite 10.0%, the total amount of rare earth is 6.2% phosphate rock as raw material, adopting mass concentration is 18% (in terms of P 2 o 5 leaching with phosphoric acid solution, control the liquid-solid ratio of the system to 4:1, react at 60°C for 0.5h, and obtain a rare earth-containing monocalcium phosphate solution and monazite-containing slag after filtration.

[0065] Sodium hydroxide is added to the solution containing the monocalcium phosphate, the pH of the solution is adjusted to 1.0, the rare earth in the solution is precipitated, and the monocalcium phosphate solution and the phosphate-containing rare earth slag are obtained after filtering. After adjusting the pH value, the content of calcium ions in the dicalcium phosphate formed in the system accounts for 2.2% of the total content of calcium ions in the system.

[0066] Add sulfuric acid to the obtained monocalcium phosphate solution to remove calcium, and separate solid and liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com