Synthetic method of polymetaphenylene diamine nanoparticle

A technology of poly-m-phenylenediamine and synthesis method, which is applied in the field of synthesis of poly-m-phenylenediamine nanoparticles with high monomer conversion rate, can solve the problem of improving the effectiveness and economy of polyarylamine synthesis reaction and affecting the industrialization of technology Application prospects, large secondary pollution and other problems, to achieve broad industrial application prospects, reduce secondary pollution problems, and improve effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

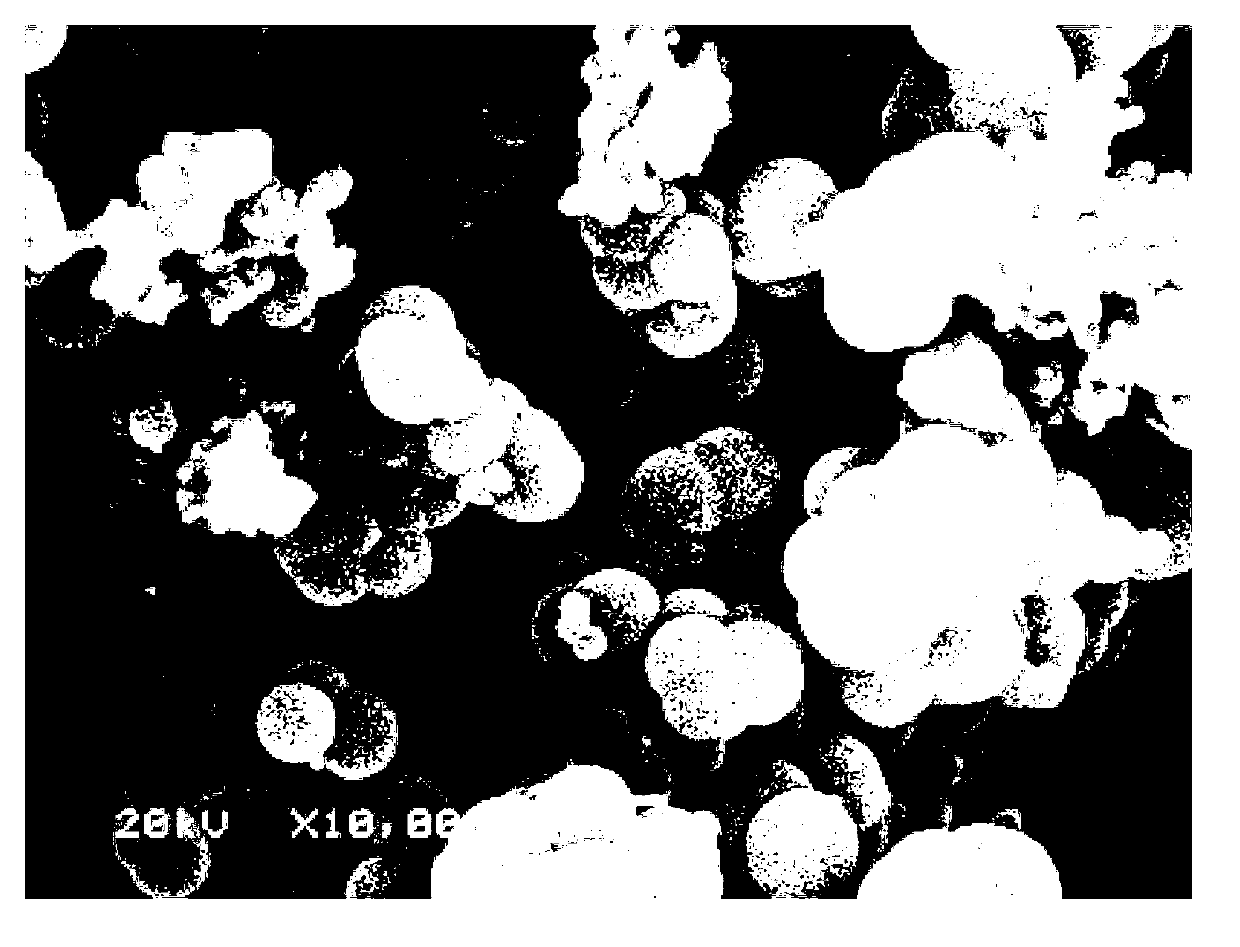

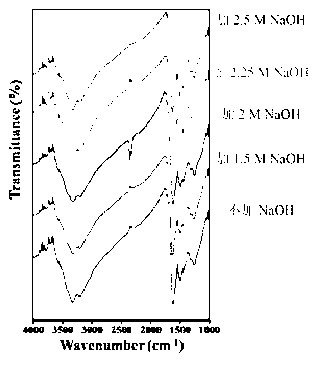

[0022] Accurately weigh 5.0 g of m-phenylenediamine and add to a 250 mL round bottom flask. Add 100ml of distilled water and stir until dissolved, keep the temperature of the monomer solution in a water bath to 30°C; accurately weigh 0.40g of copper chloride dihydrate and dissolve it in 10mL of distilled water, keep the temperature of the copper ion solution in a water bath to 30°C, and quickly Add it to the m-phenylenediamine solution for pre-reaction, and the solution turns from clear and colorless to dark yellow-brown rapidly. Accurately weigh 11g of sodium persulfate and dissolve it in 37ml of distilled water to fully dissolve it, and keep the temperature of the sodium persulfate solution in a water bath to 30°C. Accurately weigh 8g of sodium hydroxide and dissolve it in 100mL of distilled water to make it fully dissolved, and take 37mL for use. Within about 30 minutes, the sodium persulfate oxidant and sodium hydroxide solution were simultaneously dropped into the soluti...

Embodiment 2~4

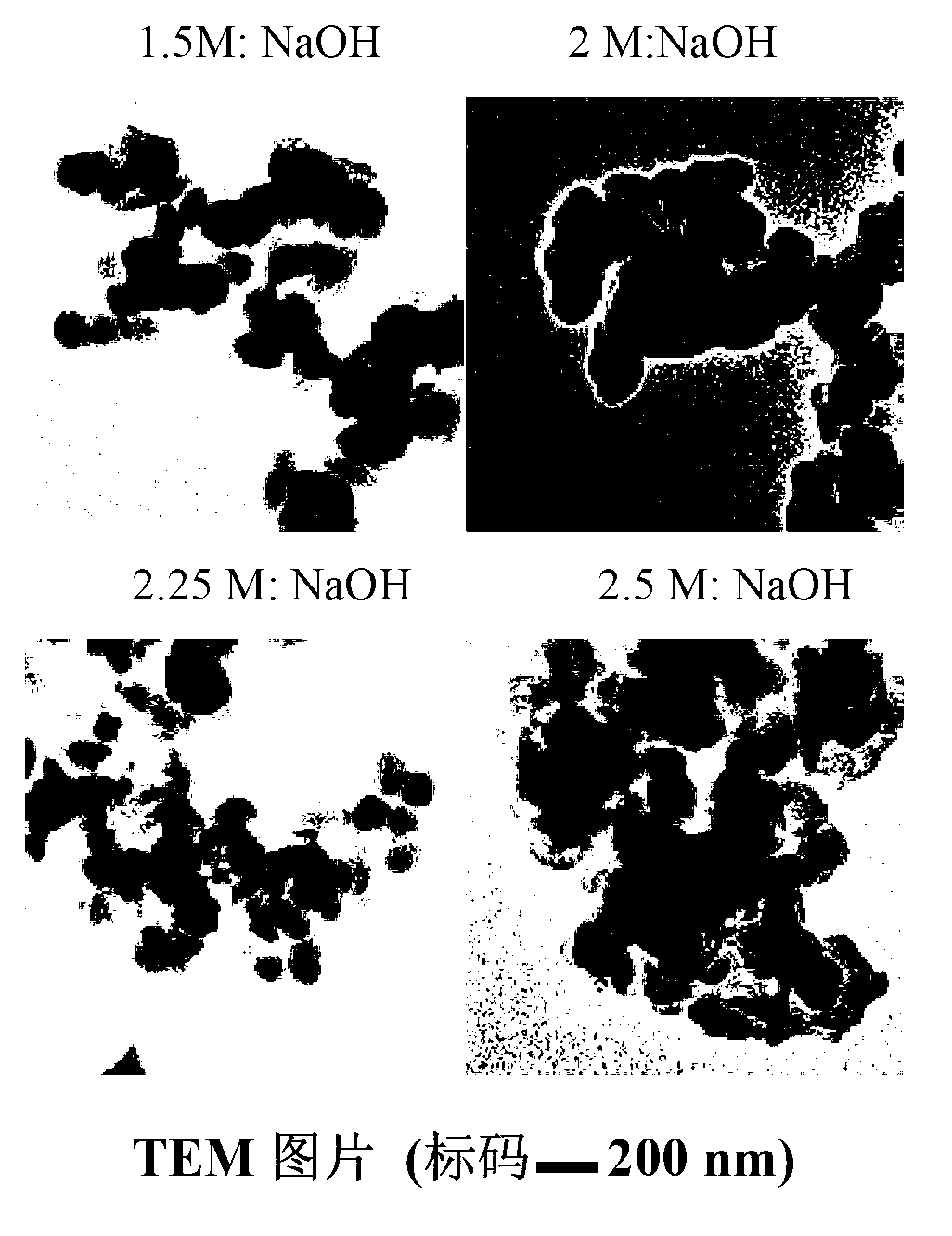

[0025] Repeat Example 1, change the concentration of sodium hydroxide solution, respectively 1.5, 2.25 and 2.5mol / L. The obtained product is a black solid powder, all of which are nano-scale poly-m-phenylenediamine. The corresponding conversion rates are as high as 90.1%, 92.6% and 91.2% respectively.

Embodiment 5

[0027] Repeat Example 1, changing the water bath insulation temperature to 0, 15, and 60 degrees. The obtained product is a black solid powder, all of which are nano-scale poly-m-phenylenediamine. The corresponding conversion rates are as high as 94.5%, 96% and 97% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com