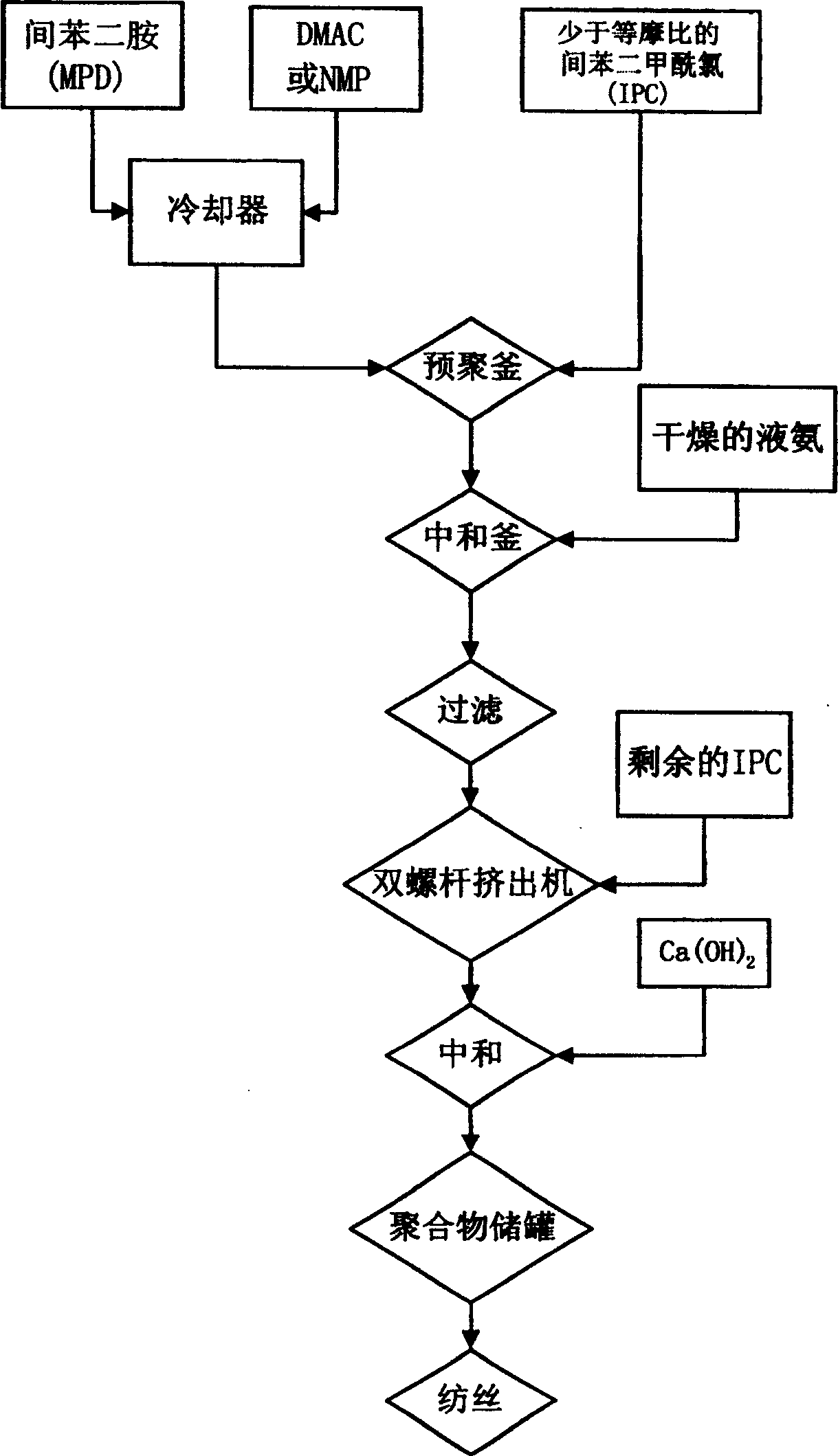

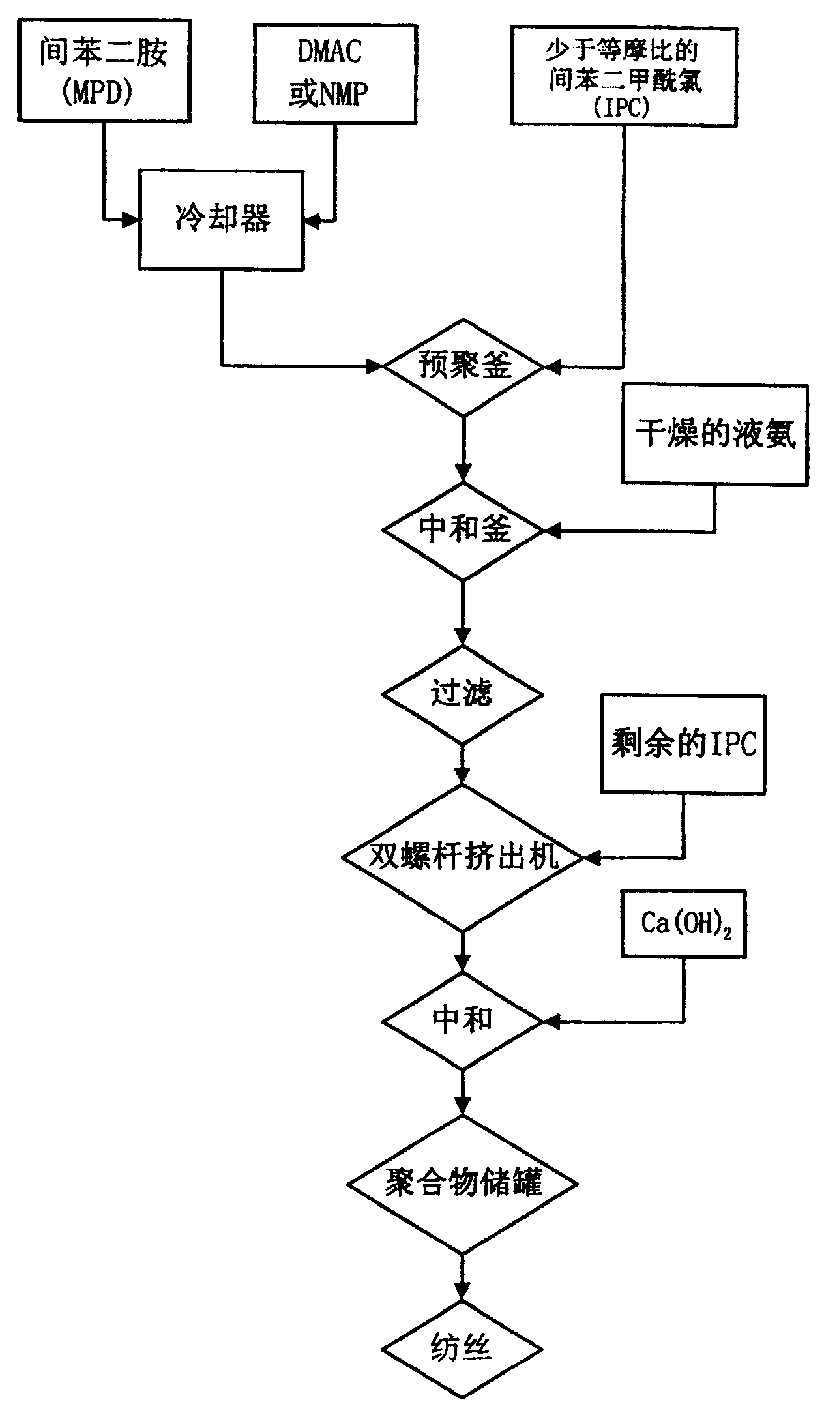

Preparation of polyisophthaloyl m-phenylene diamide spinning solution by using semi-continuous twin screw extruder

A technology of polym-phenylene isophthalamide spinning and isophthaloyl chloride, which is applied in the direction of spinning solution preparation, single-component polyamide artificial filament, etc., and can solve the problem that equimolar ratio is difficult to grasp, reaction Heat is not easy to remove, filtration is difficult, etc., to avoid the effect of molecular weight inhomogeneity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dissolve one part of refined MPD in 8.7 parts of freshly distilled dry DMAC, add 1.7 parts of 60 °C refined IPC at -10 °C for prepolymerization to form a prepolymer containing hydrogen chloride, keep the temperature below 0 °C , After reacting for 20 minutes, add 0.27 parts of dry liquid ammonia under stirring at 0°C and keep it for 20 minutes to precipitate most of the hydrogen chloride, then press filter to remove the ammonium chloride crystals generated by the reaction, and keep the filtration temperature not exceeding 10°C . The filtrate and the remaining 0.177 parts of IPC enter a twin-screw extruder with a diameter of 25 mm, an aspect ratio of 1:40, and a rotational speed of 200 rpm, and the IPC is added in a molten state. Control the temperature of the twin-screw reactor below 50°C, extrude a colorless and transparent polymer for about 12 minutes, and then carry out the second neutralization, Ca(OH) 2 The amount is 0.084 parts. Finally, a polymer containing 19....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com