Waste gas treatment process and device in isophthaloyl dichloride/paraphthaloyl chloride production

A technology for treating terephthaloyl chloride and waste gas, which is applied in the fields of inorganic chemistry, sulfur compounds, and dispersed particles. It can solve the problems of difficult treatment of sulfite solution, low recovery rate of sulfur dioxide gas, and neglect of waste gas treatment, etc., and achieve reduction Output, easy operation, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

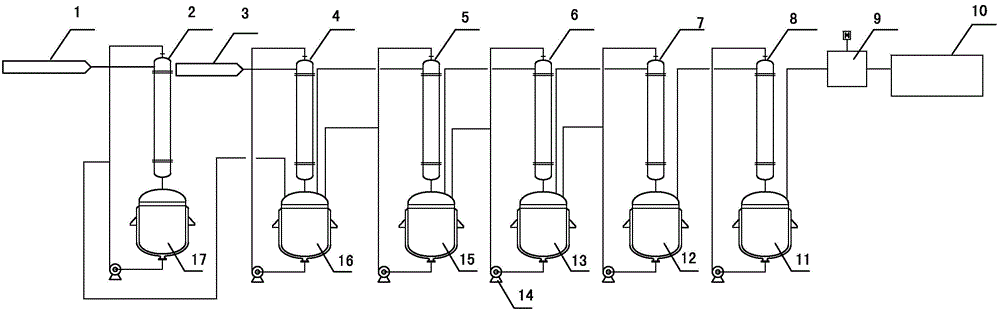

[0030] Sulfur dioxide and hydrogen chloride waste gas 3 produced in the reaction process using thionyl chloride to prepare m / terephthaloyl chloride enter the top of the primary absorption tower 4, and the unabsorbed waste gas enters the secondary absorption tower 5 through the top of the primary absorption tank 16 At the top, the remaining waste gas enters the top of the third-stage absorption tower 6 through the top of the second-stage absorption tank 15, and then enters the top of the fourth-stage absorption tower 7 through the top of the third-stage absorption tank 13, and the remaining sulfur dioxide gas passes through the fourth-stage absorption tank 12 after the fourth-stage absorption. The top enters the top of the drying tower 8, and the dried sulfur dioxide gas enters the sulfur dioxide pressurization device 9 from the top of the dry absorption tank 11, and the pressurized sulfur dioxide gas is transported to the thionyl chloride preparation device 10 for utilization, a...

Embodiment 2

[0032] The device structure of this embodiment is the same as that of Embodiment 1, the difference is that the gas phase entering the absorption tower, drying tower, and alkali absorption tower is absorbed by taking in air from the bottom of the tower and outlet from the top of the tower.

Embodiment 3

[0034] The device structure of this embodiment is the same as that of Embodiment 1. The gas phase entering the drying tower is absorbed by the way of air intake at the top of the tower and gas outlet at the bottom of the tower. The difference is that both the gas phase entering the absorption tower and the alkali absorption tower adopt the air intake at the bottom of the tower. , Absorption is carried out by way of gas outlet from the top of the tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com