Preparation method of aramid fiber paper coated with aramid fiber spinning solution

A technology of spinning stock solution and aramid paper, which is applied in the direction of special paper, textiles, papermaking, coating, etc., can solve the problems of complex preparation process of aramid nanofibers, unfavorable industrial production, secondary pollution, etc., and achieve the reduction of electronic wear. The effect of crossing the path, easy recycling and improving the dielectric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method for coating aramid paper with aramid spinning stock solution, comprising the following steps:

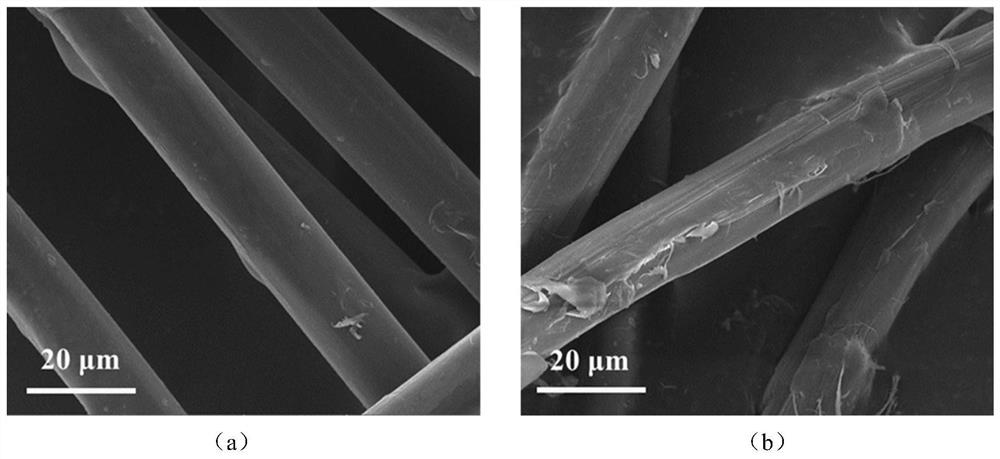

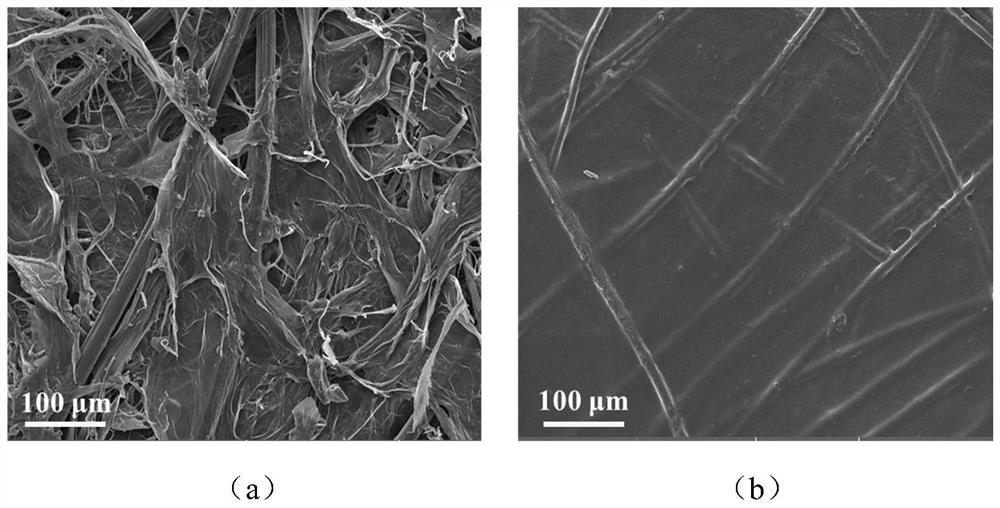

[0026] (1) Preparation of aramid paper: wash the meta-aramid chopped fibers required for the experiment in a sodium dodecylbenzenesulfonate (LAS) solution, and control the concentration of the LAS solution at 1.2×10 -3 mol / L, the washing water temperature is 60°C, soak the meta-chopped fibers, stir and wash them for about 30 minutes, finally rinse them with clean water, remove them, shred them and dry them for later use. After adding 2 / 3 of water into the fiber deflagging machine, take a certain amount of meta-aramid precipitated fiber and meta-aramid chopped fiber into it respectively, and the absolute dry mass ratio of the two is (2~4) :1. Add polyethylene oxide (PEO) solution (mass concentration: 0.05%) as a dispersant in an amount of 0.5% relative to the absolute dry meta-aramid chopped fibers, and decompose 20000r in a decomposer to obtain a slurry ...

Embodiment 1

[0038] A preparation method for coating aramid paper with aramid spinning stock solution, comprising the following steps:

[0039] (1) Preparation of aramid paper: wash meta-aramid chopped fibers in sodium dodecylbenzenesulfonate (LAS) solution, and control the concentration of LAS at 1.2×10 -3 mol / L, the washing water temperature is 60°C, soak the meta-chopped fibers, stir and wash them for about 30 minutes, finally rinse them with clean water, remove them, shred them and dry them for later use. After adding 2 / 3 of water into the fiber deflagging machine, take a certain amount of meta-aramid precipitated fiber and meta-aramid chopped fiber into it respectively, the absolute dry mass ratio of the two is 2:1, add Polyethylene oxide (PEO) solution (mass concentration: 0.05%) is used as a dispersant, and the addition amount is 0.5% relative to the absolute dry meta-aramid short-cut fiber, and it is decomposed in a decomposer for 20000r to obtain a slurry dispersion. Then the slu...

Embodiment 2

[0044] A preparation method for coating aramid paper with aramid spinning stock solution, comprising the following steps:

[0045] (1) Preparation of aramid paper: wash meta-aramid chopped fibers in sodium dodecylbenzenesulfonate (LAS) solution, and control the concentration of LAS at 1.2×10 -3 mol / L, the washing water temperature is 60°C, soak the meta-chopped fibers, stir and wash them for about 30 minutes, finally rinse them with clean water, remove them, shred them and dry them for later use. After adding 2 / 3 of water into the fiber deflagging machine, take a certain amount of meta-aramid precipitated fiber and meta-aramid chopped fiber into it respectively, the absolute dry mass ratio of the two is 2:1, add Polyethylene oxide (PEO) solution (mass concentration: 0.05%) is used as a dispersant, and the addition amount is 0.5% relative to the absolute dry meta-aramid short-cut fiber, and it is decomposed in a decomposer for 20000r to obtain a slurry dispersion. Then the slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com