Preparation method for copolymerization modification aramid 1313 fiber

A technology of copolymerization modification and aramid fiber is applied in the field of spinning fibers, which can solve the problems of complicated operation, high process cost, increase process flow, etc., and achieve the effects of low process cost, simple operation and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

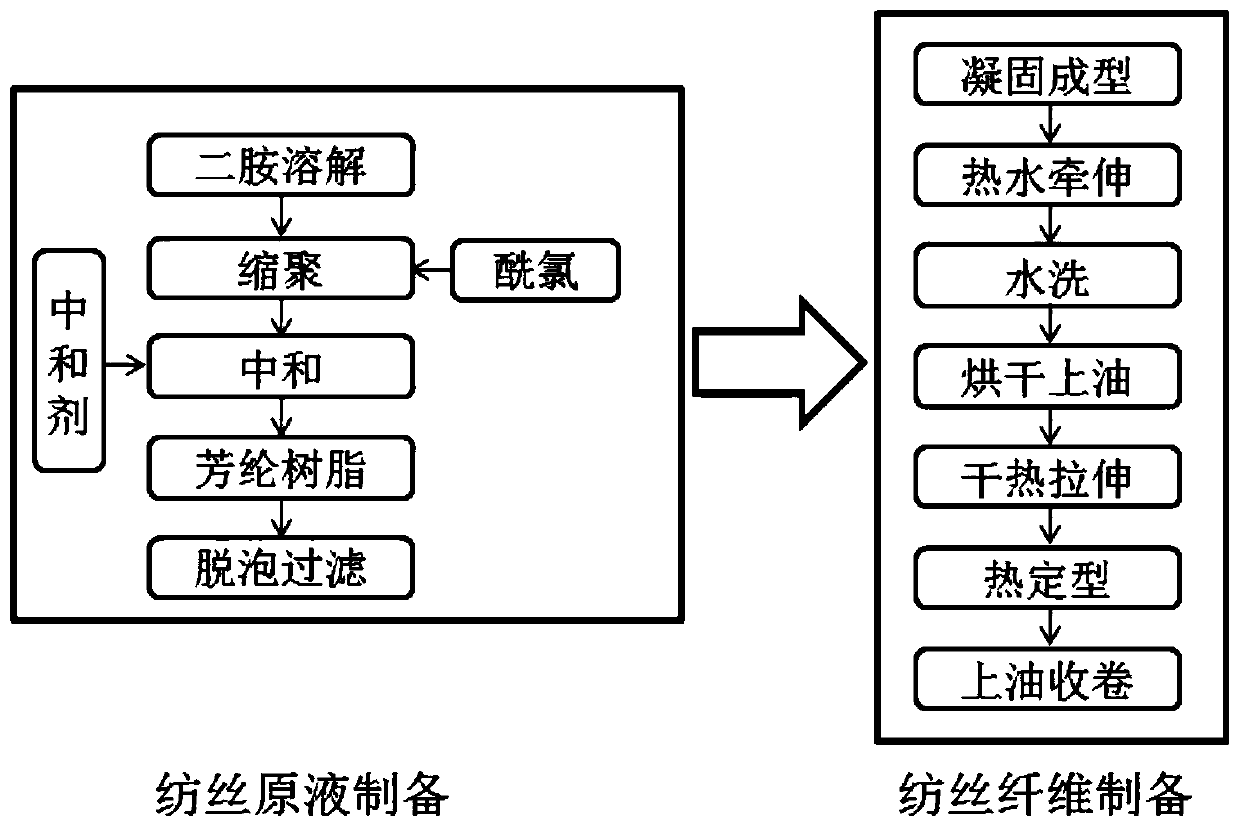

[0039] A kind of preparation method of copolymerization modified aramid fiber 1313 fiber of the present invention, its technological process schematic diagram is as figure 1 shown, including the following steps:

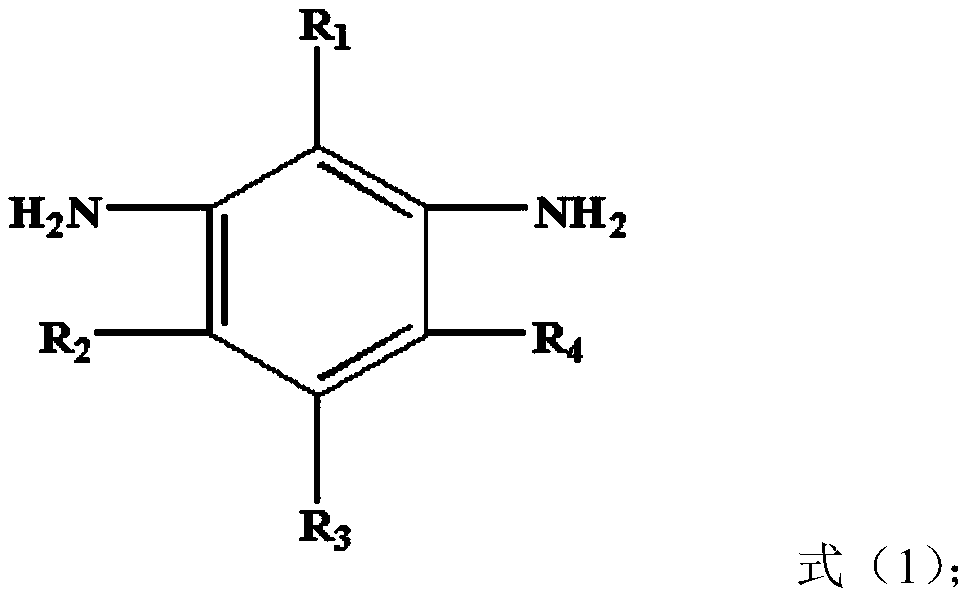

[0040] (1) dissolving m-phenylenediamine and 3,5-diaminobenzoic acid in N,N-dimethylacetamide at a molar ratio of 1:0.1 to obtain a mixed solution, and cooling the mixed solution to -15°C; The isophthaloyl chloride is melted and kept at a temperature of 50°C; the molar ratio of diamine (including m-phenylenediamine and aromatic diamine with polar groups) to isophthaloyl chloride is 1: 1.03, the mixed solution and isophthaloyl chloride were mixed and reacted at 0°C to obtain a copolymerized modified aramid 1313 solution containing hydrogen chloride. The content of the copolymerized modified aramid 1313 resin in the solution was 18.5%, and the logarithmic density The viscosity is 2.18;

[0041] (2) Using ammonia gas to neutralize the hydrogen chloride in the copolyme...

Embodiment 2

[0044] A kind of preparation method of copolymerization modified aramid fiber 1313 fiber of the present invention, its technological process schematic diagram is as figure 1 shown, including the following steps:

[0045] (1) dissolving m-phenylenediamine and 3,5-diaminobenzoic acid in N,N-dimethylacetamide at a molar ratio of 1:0.25 to obtain a mixed solution, and cooling the mixed solution to -15°C; Melting isophthaloyl chloride, keeping its temperature at 48°C; according to the molar ratio of diamine (including m-phenylenediamine and aromatic diamine with polar groups) to isophthaloyl chloride is 1: 1.04, the mixed solution and isophthaloyl chloride were mixed and reacted at 10°C to obtain a copolymerized modified aramid 1313 solution containing hydrogen chloride. The content of the copolymerized modified aramid 1313 resin in the solution was 21%, and the logarithmic density The viscosity is 2.02;

[0046] (2) Using LiOH to neutralize the hydrogen chloride in the copolymer...

Embodiment 3

[0049] A kind of preparation method of copolymerization modified aramid fiber 1313 fiber of the present invention, its technological process schematic diagram is as figure 1 shown, including the following steps:

[0050] (1) dissolving m-phenylenediamine and 3,5-diaminobenzoic acid in N,N-dimethylacetamide at a molar ratio of 1:0.6 to obtain a mixed solution, and cooling the mixed solution to -15°C; The isophthaloyl chloride is melted and kept at a temperature of 50°C; the molar ratio of diamine (including m-phenylenediamine and aromatic diamine with polar groups) to isophthaloyl chloride is 1: 1.05, the mixed solution and isophthaloyl chloride were mixed and reacted at 5°C to obtain a copolymerized modified aramid 1313 solution containing hydrogen chloride. The content of the copolymerized modified aramid 1313 resin in the solution was 20%, and the logarithmic density The viscosity is 1.85;

[0051] (2) Using LiOH to neutralize the hydrogen chloride in the copolymerized mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com