Method for polymerizing polymerized continuous solution of aromatic polyamide

A polyaramide and a polymerization method technology, which is applied in the field of continuous solution polymerization of polyaramide prepolymerization, can solve the problems of difficulty in filtration, high viscosity of the prepolymer, regular cleaning and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

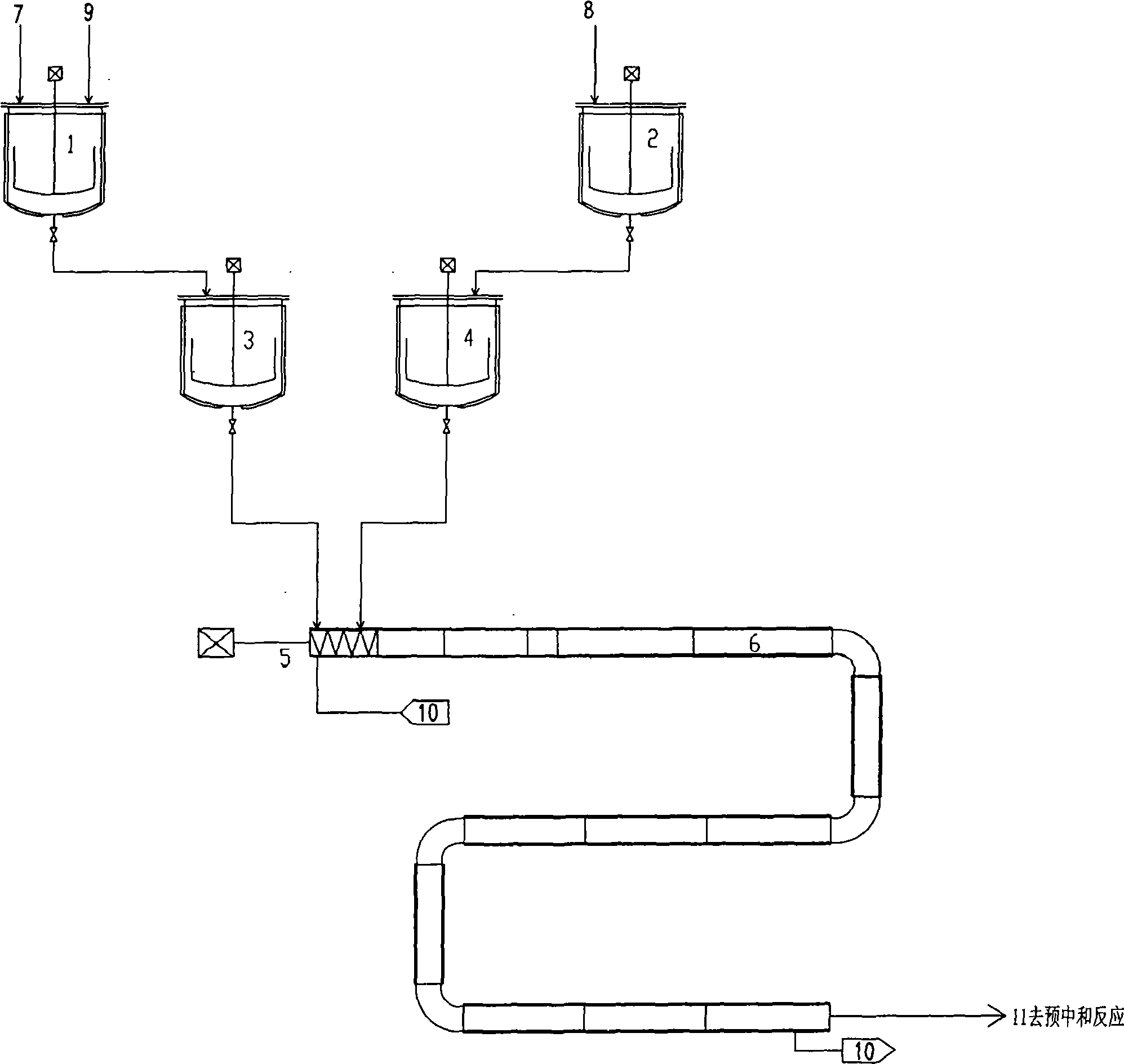

[0031] Add 1500kg of N in diamine dissolving kettle 1, N-dimethylacetamide (DMAC) or N, N-dimethylformamide or hexamethylacetamide or N-dimethylpyrrolidone 9, the system temperature Reduce to 5 degrees, slowly add 150kg of m-phenylenediamine (MPDA) 7 in molten state under stirring, fully stir, after completely dissolving, put into diamine solution temporary storage tank 3 for subsequent use; 141.2kg of pulverized acid chlorides 8 in a solid state, the temperature of the system is adjusted to 50 degrees, and after all of them become uniform liquids, put them into the acid chloride melt temporary storage tank 4 for subsequent use.

[0032] The m-phenylenediamine (MPDA) solution is pumped into the high-speed dynamic mixer 5 with a metering pump at a flow rate of 50 kg / h, and mixed with the acid chloride (IPC) sent with a metering pump at a flow rate of 4.28 kg / h. The mixed reaction solution enters the static mixer 6 pipeline. The mixer or static mixer is cooled with circulating ...

Embodiment 2

[0034] Add 1600kg of N in diamine dissolving kettle 1, N-dimethylacetamide (DMAC) or N, N-dimethylformamide or hexamethylacetamide or N-dimethylpyrrolidone 9, the system temperature Reduce to 20 degrees, slowly add 180kg of m-phenylenediamine (MPDA) 7 in a solid state under stirring, fully stir, after completely dissolving, put into diamine solution temporary storage tank 3 for subsequent use; add in acid chloride melting kettle 2 271.08 kg of pulverized acid chlorides 8 in a solid state, the temperature of the system was adjusted to 65 degrees, and after all of them became uniform liquids, they were put into the acid chloride melt temporary storage tank 4 for subsequent use.

[0035] The m-phenylenediamine (MPDA) solution is pumped into the high-speed dynamic mixer 5 with a metering pump at a flow rate of 80 kg / h, and mixed with the acid chloride (IPC) sent with a metering pump at a flow rate of 12.18 kg / h. The mixed reaction solution enters the static mixer 6 pipeline. The ...

Embodiment 3

[0037] Add 1800kg of N in diamine dissolving kettle 1, N-dimethylacetamide (DMAC) or N, N-dimethylformamide or hexamethylacetamide or N-dimethylpyrrolidone 9, the system temperature Reduce to 30 degrees, slowly add 230kg of m-phenylenediamine (MPDA) 7 in a solid state under stirring, fully stir, after completely dissolving, put into diamine solution temporary storage tank 3 for subsequent use; add in acid chloride melting kettle 2 The acid chloride 8 of the pulverized solid state of 432kg, system temperature is adjusted to 70 degree, after treating that all become uniform liquid, put into acid chloride melt temporary storage tank 4 for subsequent use.

[0038] The m-phenylenediamine (MPDA) solution is pumped into the high-speed dynamic mixer 5 with a metering pump at a flow rate of 100 kg / h, and mixed with the acid chloride (IPC) sent with a metering pump at a flow rate of 21.28 kg / h. The mixed reaction solution enters the static mixer 6 pipeline. The mixer or static mixer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com