Preparation method for multifunctional nylon stabilizer

A multi-functional, stabilizer technology, applied in the direction of organic chemistry, can solve the problems of not being able to transfer to regular production plants, and achieve economic benefits, waste water consumption and load reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

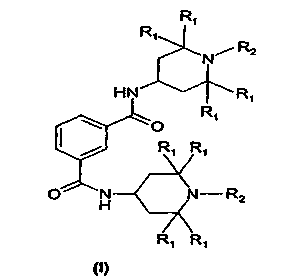

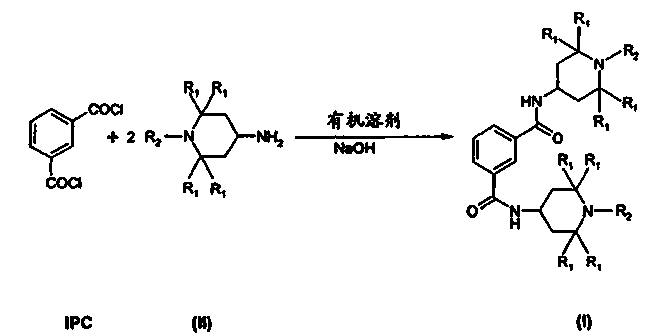

[0030] A kind of preparation method of nylon multifunctional stabilizer of the present invention, its reaction principle is

[0031]

Embodiment 1

[0034] Prepare 102.5g of isophthaloyl dichloride (99.0%; 0.50mol) as solid particles, 159.5g of 2,2,6,6-tetramethylpiperidin-4-ylamine (98.0%; 1.0mol), 81.6g of 50% NaOH solution (1.02 mol), 81.40 g dichloromethane.

[0035] Mix 2,2,6,6-tetramethylpiperidin-4-ylamine and chloroform in a 2-liter flask with a stirrer, dropping funnel and thermometer, and add gradually under stirring at a temperature of 20°C NaOH solution and isophthaloyl chloride, maintain described temperature and stirring condition, add time control at 50 minutes, reaction mixture is heated to reflux temperature, distillation reclaims solvent, will add the water of appropriate amount in the process of distilling solvent, It is used to disperse the product, cool to room temperature after the reflux is completed, and separate the target nylon multifunctional stabilizer product.

Embodiment 2

[0037] Prepare 100g of isophthaloyl chloride (99.0%; 0.49mol) as solid particles, 159.5g of 2,2,6,6-tetramethylpiperidin-4-ylamine (98.0%; 1.0mol), 81.6g of 50% NaOH Solution (1.02mol), 91.8g chloroform.

[0038] Mix 2,2,6,6-tetramethylpiperidin-4-ylamine and chloroform in a 2-liter flask with a stirrer, dropping funnel and thermometer, and add gradually under stirring at a temperature of 20°C NaOH solution and isophthaloyl chloride, maintaining the temperature and stirring conditions, adding time is controlled at 60 minutes, the reaction mixture is heated to the reflux temperature, the solvent is recovered by distillation, and an appropriate amount of water will be added in the process of solvent distillation. It is used to disperse the product, cool to room temperature after the reflux is completed, and separate the target nylon multifunctional stabilizer product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com