Production process for preventing discoloration of aramid polymerized size

A production process and slurry technology, applied in the direction of single-component synthetic polymer rayon, single-component polyamide rayon, fiber chemical characteristics, etc. Processing and other problems, to prevent discoloration and solve the effect of discoloration of slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

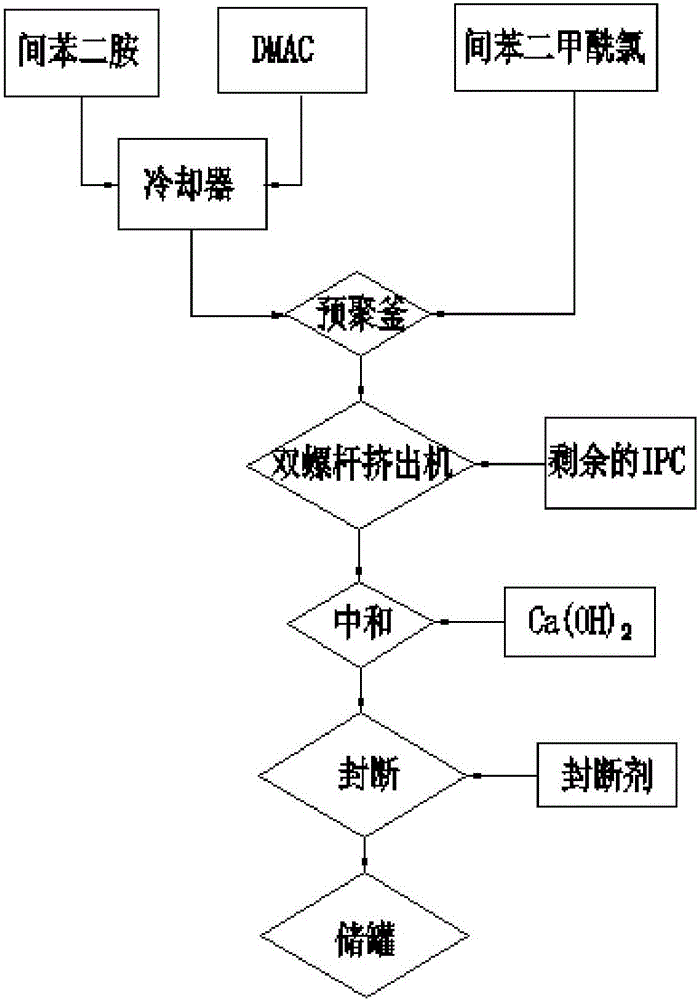

[0015] as attached figure 1 Shown is a flow chart of a production process for preventing aramid polymerization slurry from discoloration according to the present invention. First, 1 part of m-phenylenediamine MPD is dissolved in a solvent of 10.92 parts of dimethylacetamide DMAC; then at -10 ° C Add 1.7 parts of isophthaloyl chloride IPC at 60°C for pre-polymerization; after polymerization, first add 2 parts of chain extender to extend the chain, and then add neutralizer Ca(OH)2 to synthesize acidic slurry, and the final pH value is controlled to 5 , and then add 0.5 parts of blocking agent to block the residual amino group of the above acidic solution. The blocking agent is acid or acid anhydride; during the above steps of reaction, control the temperature of the slurry to be lower than 70°C, and finally filter and defoam and apply it to spinning and pulping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com