A micro-reaction system and method for preparing p-/meta-aramid fibers

A micro-reaction and micro-reactor technology, which is applied in the field of micro-reaction systems for preparing para/meta-aramid fibers, can solve the problems of poor repeatability of product properties, affecting the dissolution spinning process, and poor controllability of the preparation process. Improves process stability and repeatability, improves product performance, and suppresses side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

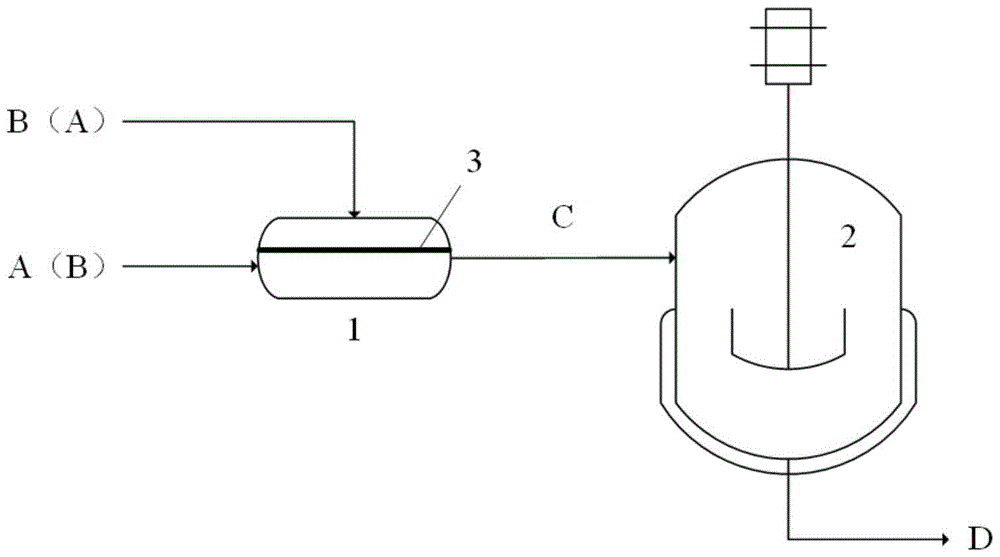

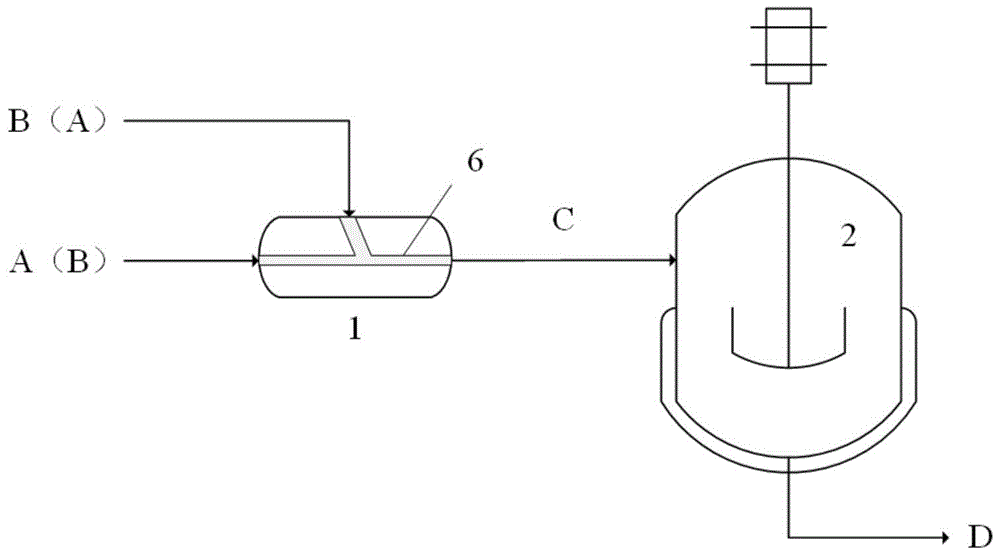

[0038] The invention discloses a preparation method of para-aramid fiber, which specifically comprises the following steps:

[0039] (1) calcium chloride is dissolved in nitrogen methyl pyrrolidone to obtain calcium chloride solution, the concentration of calcium chloride is 10%, p-phenylenediamine is dissolved in calcium chloride solution, and pyridine is added, wherein, p-phenylenediamine Concentration is 0.600mol / L, and the concentration ratio of pyridine and p-phenylenediamine is 5, obtains reaction solution A; Dissolves terephthaloyl dichloride in calcium chloride solution, and the concentration of terephthaloyl dichloride is 0.606mol / L, obtains reaction Liquid B;

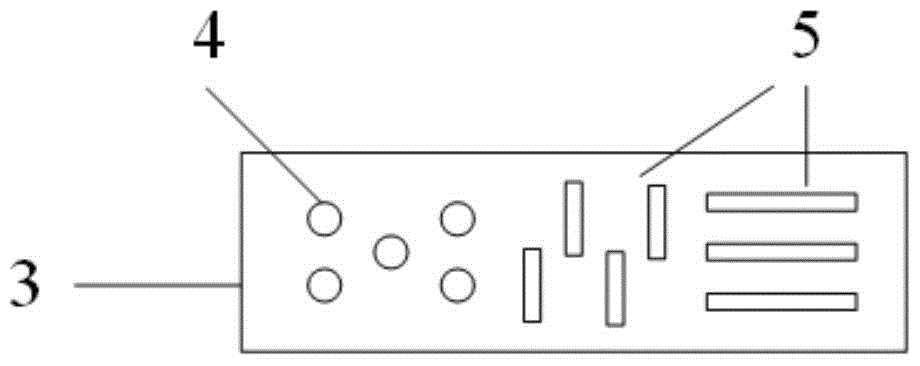

[0040] (2) Mix reaction solution A and reaction solution B in the microreactor and cause polycondensation reaction to obtain reaction solution C; there is a microstructure distribution plate with a diameter of 0.04mm mesh in the microreactor; The reaction temperature is 0°C, and the time is 100s;

[0041] (3...

Embodiment 2

[0045] The invention discloses a preparation method of para-aramid fiber, which specifically comprises the following steps:

[0046] (1) Calcium chloride is dissolved in dimethylacetamide to obtain calcium chloride solution, the concentration of calcium chloride is 0.01%, p-phenylenediamine is dissolved in calcium chloride solution, and pyridine is added, wherein, p-phenylenediamine The concentration of pyridine and p-phenylenediamine is 0.01mol / L, and the concentration ratio of pyridine and p-phenylenediamine is 0.1 to obtain reaction solution A; terephthaloyl chloride is dissolved in calcium chloride solution, and the concentration of terephthaloyl chloride is 0.01mol / L to obtain Reaction solution B;

[0047] (2) Mix reaction solution A and reaction solution B in a microreactor and cause polycondensation reaction to obtain reaction solution C; there is a microstructure distribution plate with a width of 0.03 mm and a length of 2 mm in the microreactor ; The reaction tempera...

Embodiment 3

[0052] The invention discloses a preparation method of para-aramid fiber, which specifically comprises the following steps:

[0053] (1) Calcium chloride is dissolved in nitrogen ethyl pyrrolidone to obtain calcium chloride solution, the concentration of calcium chloride is 4%, p-phenylenediamine is dissolved in calcium chloride solution, and pyridine is added, wherein, p-phenylenediamine Concentration is 0.5mol / L, and the concentration ratio of pyridine and p-phenylenediamine is 0.2, obtains reaction solution A; Dissolves terephthaloyl chloride in calcium chloride solution, and the concentration of terephthaloyl chloride is 0.505mol / L, obtains reaction Liquid B;

[0054] (2) Mix reaction solution A and reaction solution B in a microreactor and cause polycondensation reaction to obtain reaction solution C; there is a microstructure distribution plate with a width of 0.05 mm and a length of 5 mm in the microreactor ; The reaction temperature in the microreactor is 25°C, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com