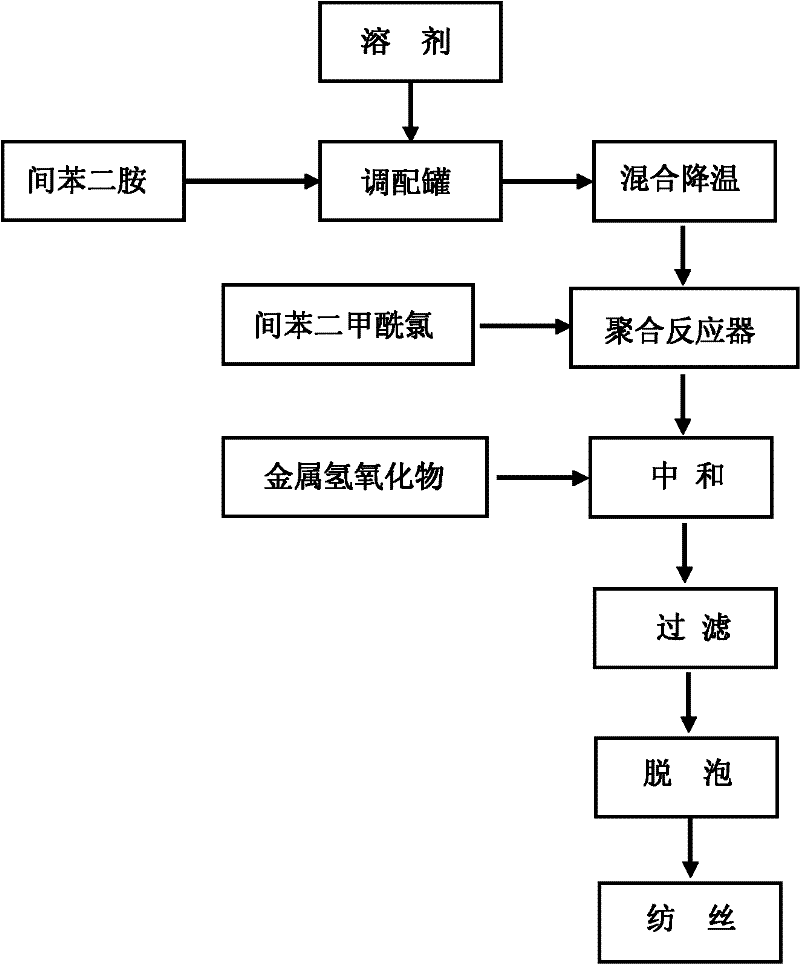

Method for continuous production of polyisophthaloyl metaphenylene diamine spinning stock solution

A technology of poly-m-phenylene isophthalamide spinning and isophthaloyl chloride is applied in the directions of single-component polyamide rayon, dry spinning, wet spinning, etc., and can solve the problem of unfavorable fiber product stability. , polymer batch differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, dissolve m-phenylenediamine in the polar solvent NMP with a concentration of 1.0mol / L. After cooling down, it enters the main polymerization reactor, and then adds a certain amount of isophthaloyl chloride, which is 60% of the total amount. %, the temperature is 0°C; after a certain period of reaction, add a total of 30% of isophthaloyl chloride in the second section of the reactor; the remaining 10% of isophthaloyl chloride is added in the third section of the reactor, and the reaction is completed The final polymer solution enters the next process. By controlling the reaction time and the ratio of the two reactants, polymers with different molecular weights can be obtained. The closer the reaction ratio is to 1, the larger the molecular weight of the polymer.

[0023] After the polymerization is completed, the hydrogen chloride produced by the polymerization is neutralized with metal hydroxide, and the produced metal chloride is dissolved in the polymer solutio...

Embodiment 2

[0026] First, dissolve m-phenylenediamine in the polar solvent DMAC with a concentration of 0.9mol / L. After cooling down, it enters the main polymerization reactor, and then adds a certain amount of isophthaloyl chloride, which is 70% of the total amount. %, the temperature is -5°C; after reacting for a certain period of time, add a total amount of 25% isophthaloyl chloride in the second section of the reactor; the remaining 5% of isophthaloyl chloride is added in the third section of the reactor, and the reaction After completion, the polymer solution enters the next process.

[0027] After the polymerization is completed, the hydrogen chloride produced by the polymerization is neutralized with metal hydroxide, and the produced metal chloride is dissolved in the polymer solution without filtering out, and contributes to the stability of the polymer solution. The polymer content in the polymer solution was 15.8%.

[0028] The polymer solution is directly used for spinning aft...

Embodiment 3

[0030] First, dissolve m-phenylenediamine in the polar solvent DMAC with a concentration of 1.2mol / L. After cooling down, it enters the main polymerization reactor, and then adds a certain amount of isophthaloyl chloride, which is 80% of the total amount. %, the temperature is 0°C; after a certain period of reaction, add a total of 18% of isophthaloyl chloride in the second section of the reactor; the remaining 2% of isophthaloyl chloride is added in the third section of the reactor, and the reaction is completed The final polymer solution enters the next process.

[0031] After the polymerization is completed, the hydrogen chloride produced by the polymerization is neutralized with metal hydroxide, and the produced metal chloride is dissolved in the polymer solution without filtering out, and contributes to the stability of the polymer solution. The polymer content in the polymer solution was 19.2%.

[0032] The polymer solution is directly used for spinning after filtering,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com