Production method for co-producing benzoyl chloride and trichlorobenzene from dichlorobenzoyl chloride

A technology for co-producing benzoyl chloride with dichlorobenzoyl chloride and a production method, which is applied in chemical instruments and methods, preparation of acid halides, preparation of organic compounds, etc. High rate and high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

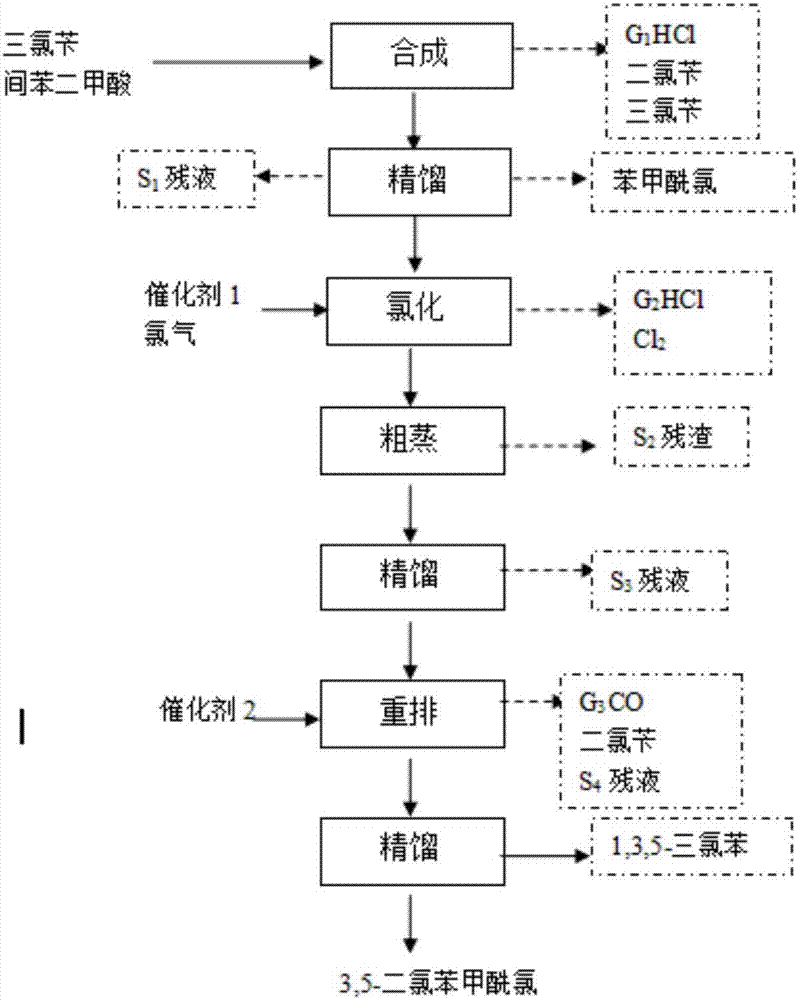

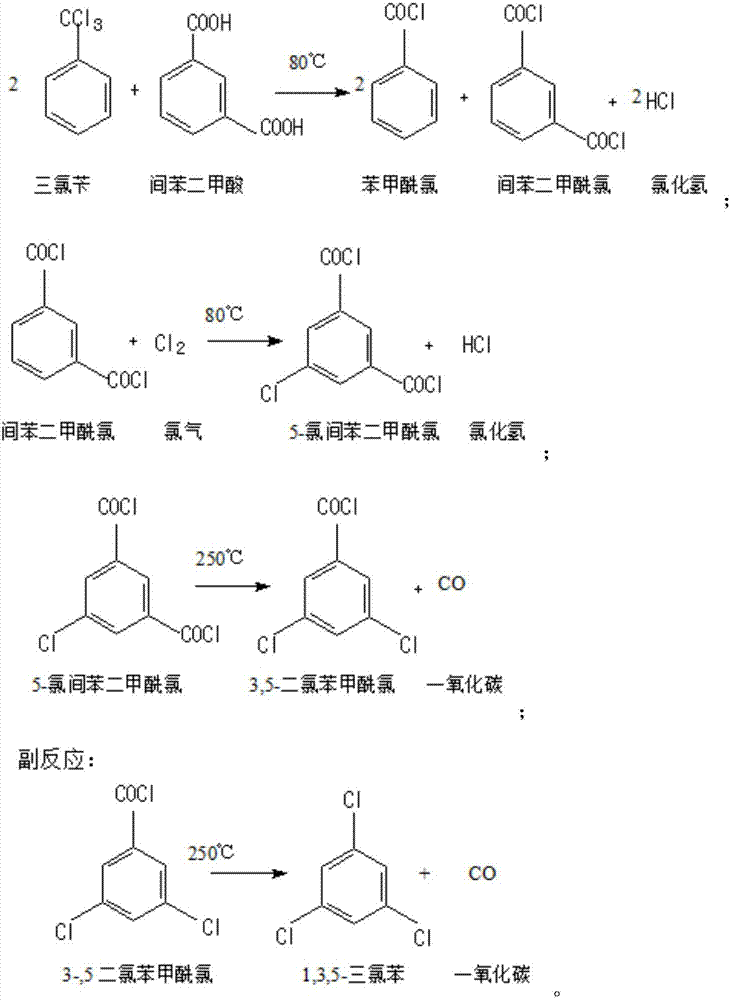

[0018] Present embodiment relates to a kind of production method of dichlorobenzoyl chloride coproduction benzoyl chloride and trichlorobenzene, such as figure 1 As shown, it specifically includes the following steps:

[0019] ①Synthesis

[0020] Put metered trichlorobenzyl and isophthalic acid into a 5000L synthesis kettle, slowly heat the steam jacket to 80°C, close the steam valve, and carry out the synthesis reaction under normal pressure. The reaction is an exothermic reaction. As the reaction temperature rises, the jacket is opened to circulate cooling water, the temperature is controlled at 100-105°C, and the single-batch reaction time is 6 hours; hydrogen chloride and a small amount of trichloride will be produced during feeding and heating. Benzyl chloride, benzyl dichloride, benzyl dichloride and benzyl trichloride are condensed and refluxed into the kettle through the condensing device at the top of the kettle, and a small amount is absorbed together with hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com