Method for preparing aromatic polyamide

A polyarylamide and copolymer technology, which is applied in the field of polyarylamide preparation, can solve the problems of large fluctuations in performance indicators, influence on enlarged production, and performance degradation, and achieve stable quality indicators, good repeatability of parts performance, and thermal stability. The effect of excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 1500g N,N'-dimethylformamide and 108g (1.0mol) m-phenylenediamine to a 3L reactor equipped with a stirrer, a thermometer, a cooler, and an inert gas protection device, and wait until it is completely dissolved at room temperature , Add a homogeneous powder mixture of isophthaloyl dichloride and terephthaloyl dichloride in 10 batches. Among them, 101.5 g (0.5 mol) of isophthaloyl dichloride and 101.5 g (0.5 mol) of terephthaloyl dichloride. The time interval between each batch of addition is 10 minutes, and the reaction is 4 hours after the addition is completed. After the polymerization reaction is completed, add 3000ml of deionized water, stir and precipitate the copolymer, filter, wash with water, dry, crush, and sieve to obtain 216g of polyaramide Copolymer powder. Dissolve 2.16g of combined antioxidant in 300g of dimethyl carbonate, mix evenly with polyaramid copolymer powder, bake at 90°C for 4h after natural ventilation for 12h, and sieve. The composition of...

Embodiment 2

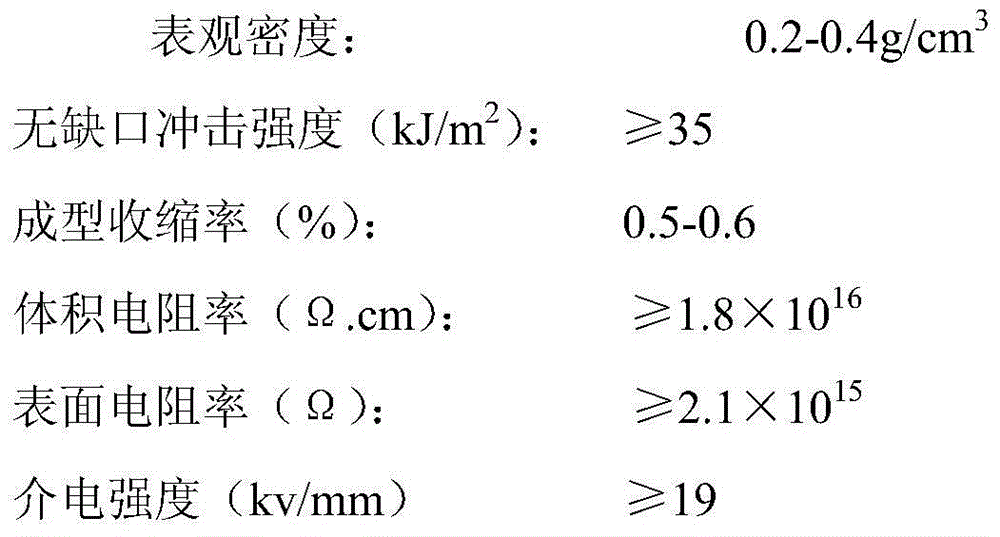

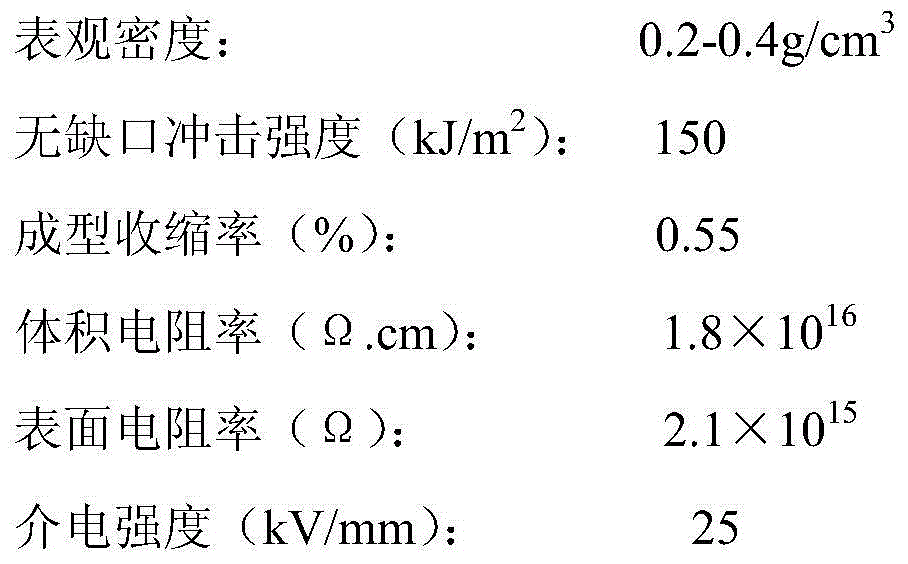

[0020] Add 1500g N,N'-dimethylformamide and 108g (1.0mol) m-phenylenediamine to a 3L reactor equipped with a stirrer, a thermometer, a cooler, and an inert gas protection device, and wait until it is completely dissolved at room temperature , Add a homogeneous powder mixture of isophthaloyl dichloride and terephthaloyl dichloride in 10 batches. Among them, 142g (0.7mol) of isophthaloyl chloride and 61g (0.3mol) of terephthaloyl chloride. The time interval between each batch of addition is 10 minutes, and the reaction is carried out for 4 hours after the addition is completed. tert-butyl-4-hydroxybenzyl) combined antioxidant composed of isocyanuric acid, after stirring evenly, precipitate polyaramid copolymer in 3000ml deionized water; filter, wash with water, dry, pulverize, sieve to obtain 219g Polyarylamide copolymer powder, measured polyarylamide copolymer, its specific viscosity is 1.2, the performance of molded sample is: unnotched impact strength 150kJ / m 2 , other perf...

Embodiment 3

[0022] In addition to adding a combined antioxidant composition of 0.86g triphenyl phosphite and 1.30g 1,3,5-tris(3,5-di-tert-butyl-4-hydroxybenzyl) isocyanuric acid, other formulas and steps Same as Example 1. The obtained polyaramid copolymer has a specific viscosity of 1.1, and the performance of the molded sample is: unnotched impact strength of 125kJ / m 2 , other performance indexes are all with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com