Process for continuously producing N-monomethylethanolamine

A technology of methyl monoethanolamine and process method, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve problems such as low yield, low selectivity, increased energy consumption, etc., and achieve good color and product quality. The effect of stable quality and increased production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

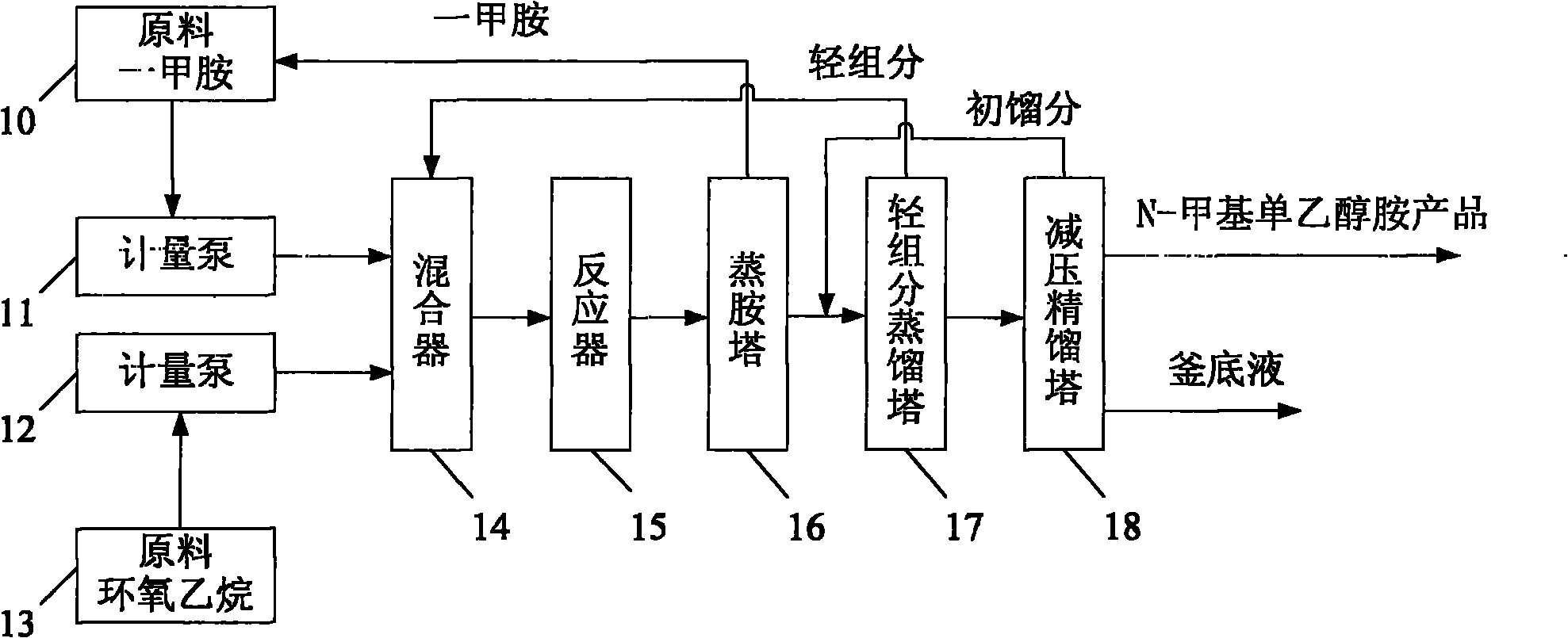

[0060] A kind of embodiment of the processing method of continuous production N-methyl monoethanolamine of the present invention is as follows figure 2 shown, including the following steps:

[0061] (1) After the raw material oxirane 13 and the raw material monomethylamine 10 are pumped into the mixer 14 by metering pumps 11 and 12 and mixed respectively, the mixed material enters the reactor 15, and in the reactor 15 The pressure is 4Mpa ~ 6Mpa, and the temperature is controlled at 90°C ~ 140°C to react to form a mixture containing N-methyl monoethanolamine.

[0062] The ratio of the raw material ethylene oxide 13 to the raw material monomethylamine 10 is 1:2-3.

[0063] (2) The mixture containing N-methyl monoethanolamine is sent to the ammonia distillation tower 16, and the crude product of monomethylamine and N-methyl monoethanolamine is separated by distillation, and the monomethylamine separated by the distillation is sent back Into the container of the raw material m...

Embodiment 2

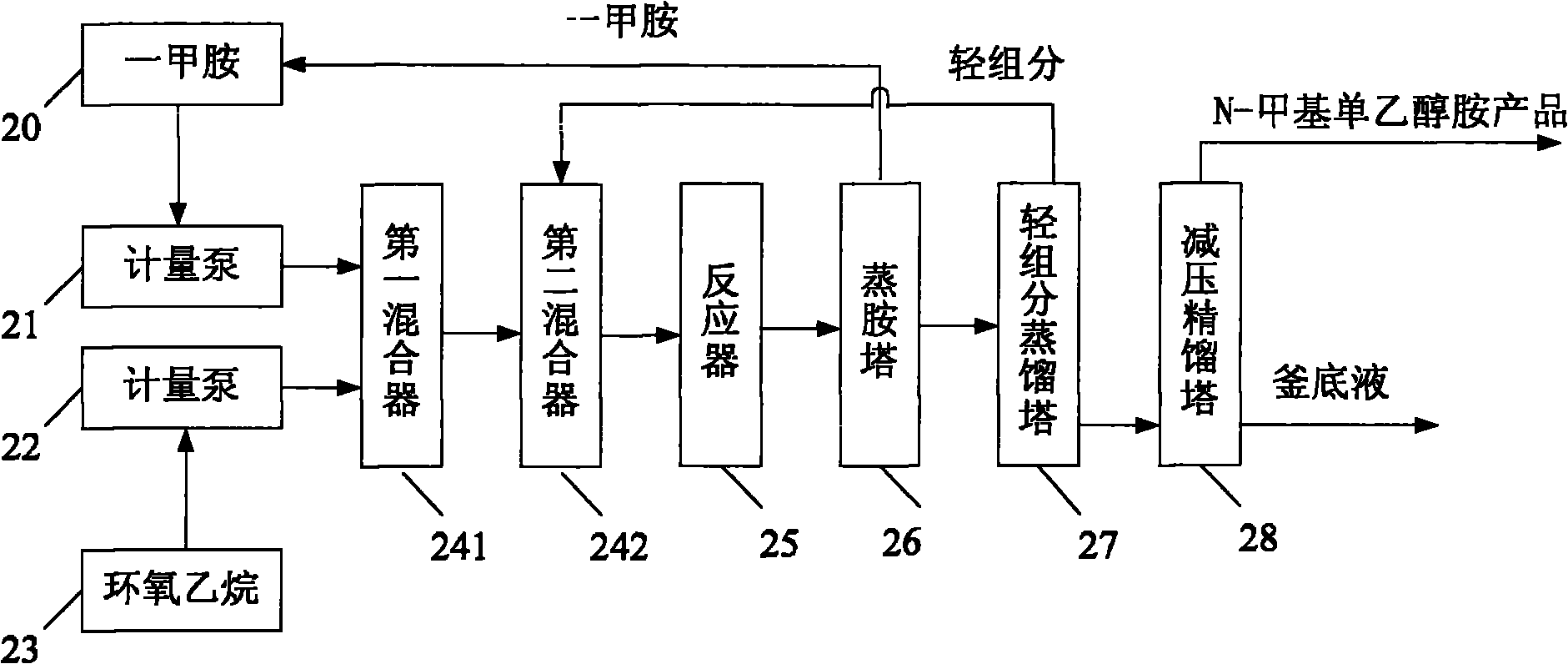

[0090] A kind of embodiment of the processing method of continuous production N-methyl monoethanolamine of the present invention is as follows image 3 shown, including the following steps:

[0091] (1) The raw material ethylene oxide 23 and the raw material monomethylamine 20 are pumped into the first mixer 241 by metering pumps 21 and 22 respectively for preliminary mixing, and then the preliminary mixed material is sent into the second mixer 242 for further mixing Finally, the further mixed material enters the reactor 25, and reacts under the pressure in the reactor 25 of 4Mpa to 6Mpa, and the temperature is controlled at 90°C to 140°C to generate a mixture containing N-methyl monoethanolamine,

[0092] The ratio of the raw material ethylene oxide to the raw material monomethylamine is 1:2-3.

[0093] (2) The mixture containing N-methyl monoethanolamine is sent to the ammonia distillation tower 26, and the crude product of monomethylamine and N-methyl monoethanolamine is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com