Multilayer fluidized solid continuous distillation column

A distillation tower and multi-layer flow technology, applied in the field of solid-state distillation equipment, can solve the problems of inability to meet the requirements of continuous distillation process, adverse effects of heat and mass transfer and distillation effect, and unstable product concentration, so as to improve processing efficiency and The output of the product, the effect of reducing labor intensity and stabilizing the concentration of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

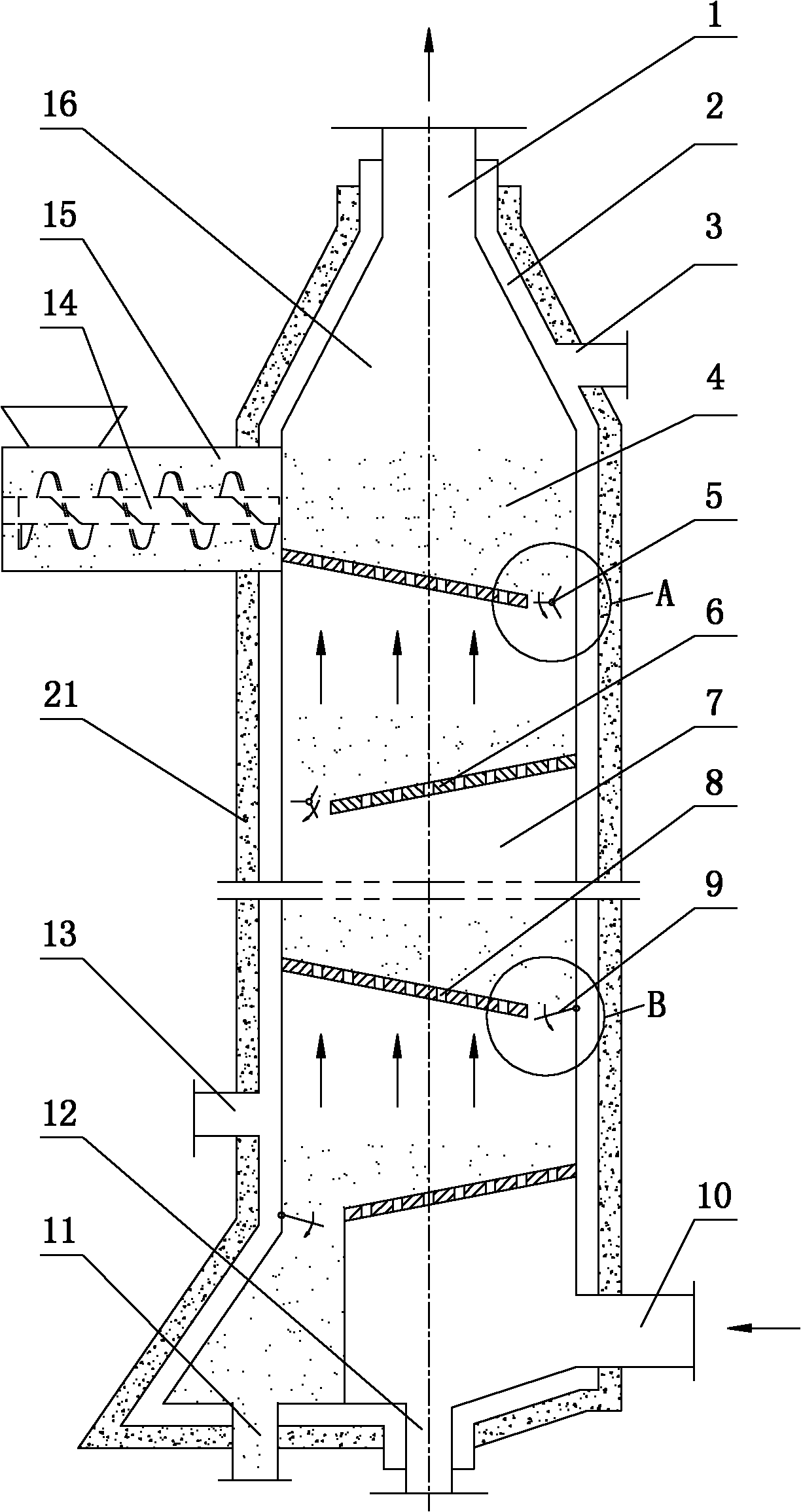

[0024] A multi-layer fluidized solid-state continuous distillation tower, comprising a rectangular tower body 16, the interior of the tower body is a distillation chamber, a mixed steam outlet 1 of waste steam and ethanol vapor is arranged at the top of the tower body, the upper part of the tower body The side wall is formed with a feed port 15, and the side wall at the lower part of the tower body is formed with a superheated steam inlet 10. The bottom of the tower body is formed with a slag outlet 11 and a cleaning liquid outlet 12. These mixed steam outlets, feed ports, and superheated steam inlets , the slag outlet and the waste liquid outlet are all connected with the distillation chamber.

[0025] The innovation of the present invention lies in that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com