Method for producing electronic grade hydrochloric acid

A production method and electronic-grade technology, applied in the direction of chlorine/hydrogen chloride purification, chlorine/hydrogen chloride, etc., can solve the problems of non-continuous large-scale production, low efficiency, low yield, cumbersome production operations, etc., and achieve continuous production and simple equipment , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

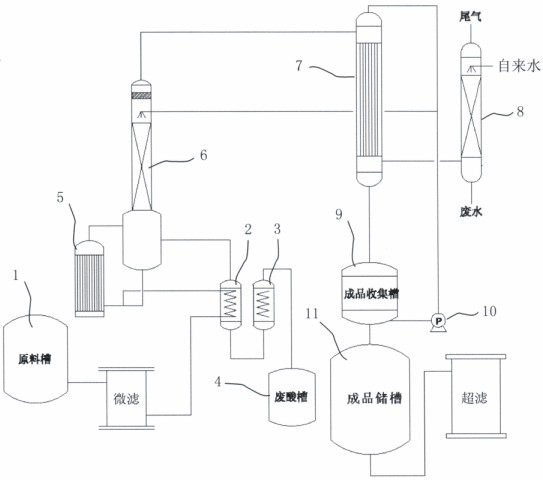

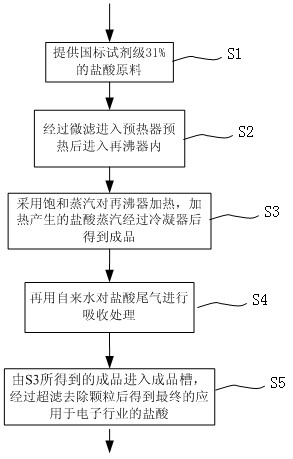

[0025] figure 1 It is a schematic diagram of the electronic grade hydrochloric acid production device of the present invention; figure 2 It is a flow chart of the electronic grade hydrochloric acid production method of the present invention.

[0026] See figure 1 and figure 2 , the electronic grade hydrochloric acid production method provided by the invention, comprises the following steps successively:

[0027] Step S1: National standard reagent grade 31% hydrochloric acid raw material, the hydrochloric acid raw material is stored in the plastic raw material tank 1;

[0028] Step S2: The above-mentioned hydrochloric acid raw material is filtered by a micron-sized PP material filter element and then enters the preheater 2 for preheating at a flow rate of 50-100kg / h, and then enters the reboiler 5. The preheater 2 is used to convert the normally di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com