Method and apparatus for separating and purifying ethyl vanillin by decompression and continuous distillation in dividing wall column

A technology for ethyl vanillin and rectification separation, which is applied in the field of separation and purification of ethyl vanillin by continuous vacuum distillation of a dividing wall column, can solve problems such as no reports, and achieve the effect of reducing investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

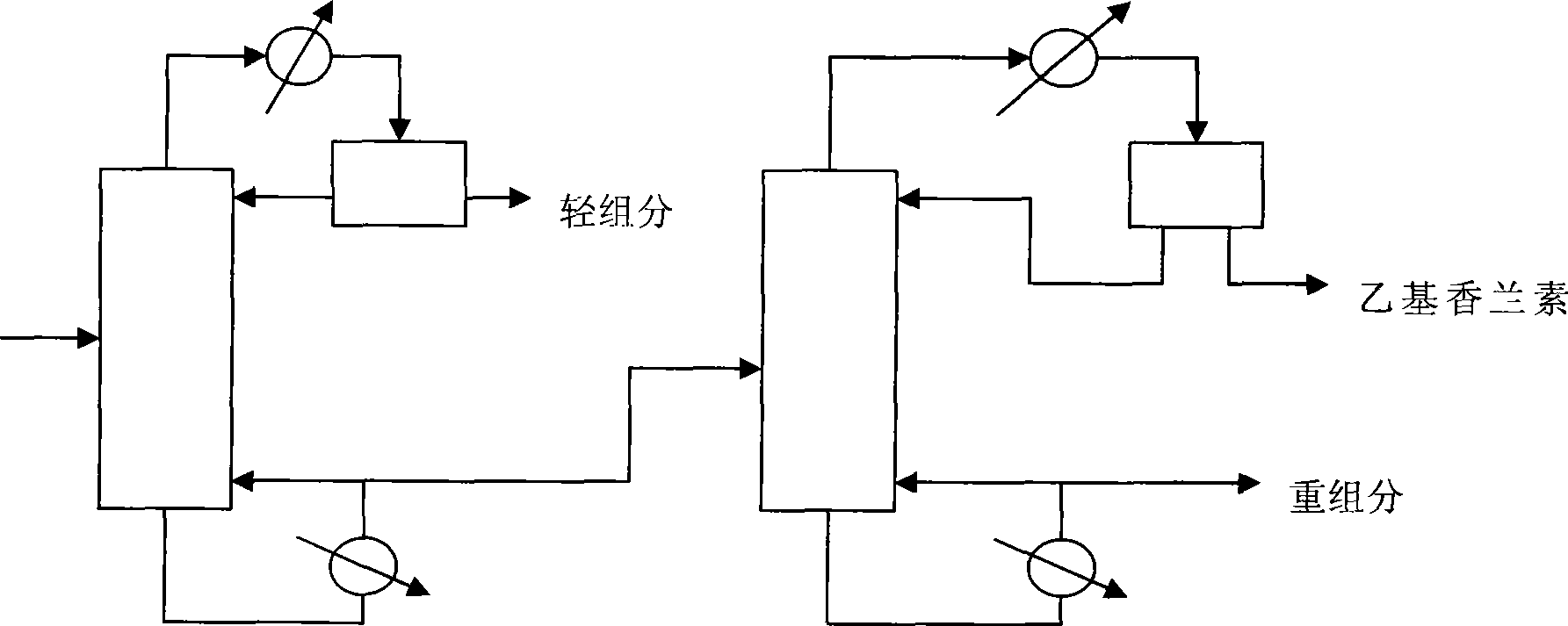

[0026] The composition of crude ethyl vanillin is as follows: light component 4.5%, ethyl vanillin 82.5%, heavy component 13%. It is separated and purified by conventional continuous distillation under reduced pressure. The diameter of the two towers is 500mm, and the height of the packing layer is 5m and 2m respectively. The vacuum degree of the tower kettle is controlled at about 10mmHg, and the falling film reboiler is heated. Feed from the first tower at a feed rate of 62.5kg / hr; extract light components from the top of the first tower; extract heavy components from the bottom of the second tower; and harvest 46.5kg / hr from the top of the second tower Ethyl vanillin was extracted at a high speed, with a purity of 99.5% and a yield of 90.2%. (see figure 1 )

Embodiment 2

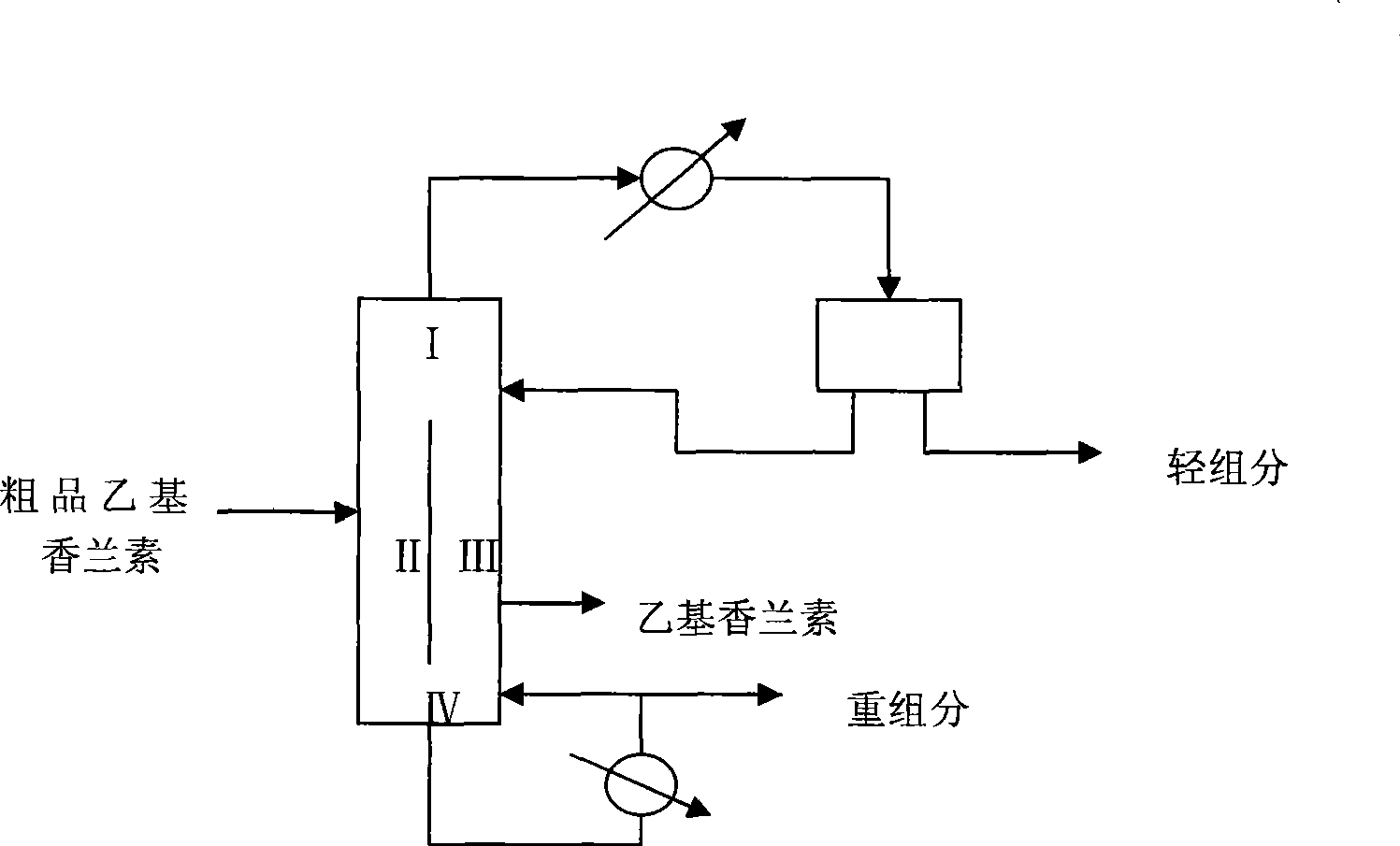

[0028] The crude ethyl vanillin in Example 1 is separated and purified by the method of the present invention. The inner diameter of the rectification tower is 500mm, and the height of the packing is 5m. Install a 2.5m high divider in the tower to make the filler height of the public rectification section I 2m, the filler height of the public stripping section IV is 0.5m, the position of the feed inlet is set at the 2.5m height filler, and the side line The mining outlet position is set at the filling height of 1m. The vacuum degree of the control tower kettle is about 10mmHg, and the falling film reboiler is heated. Feed from the upper part of zone II at a feed rate of 62.5kg / hr; extract light components from the top of zone I; extract heavy components from the bottom of zone IV; extract from the middle and lower side lines of zone III at a rate of 49.1kg / hr Ethyl vanillin was obtained with a purity of 99.5% and a yield of 95.2%. (see figure 2 )

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com