High-efficiency energy-saving white wine continuous distillation method and device

A high-efficiency energy-saving, distillation method technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of low efficiency, non-continuous production, high energy consumption, etc., and achieve the effects of reducing injuries, high production efficiency, and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

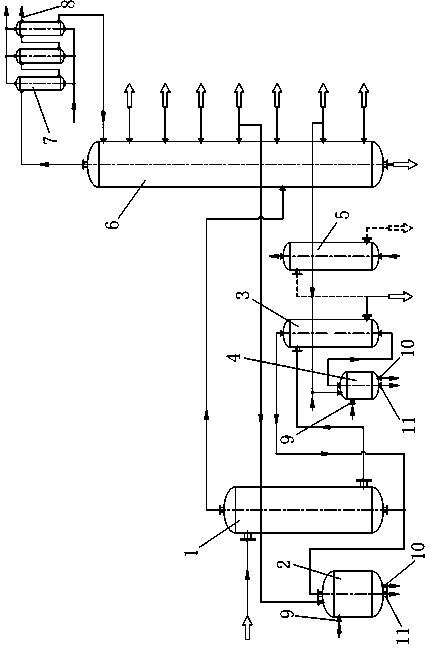

[0028] A high-efficiency and energy-saving liquor continuous distillation method, comprising the following steps:

[0029] Put the distiller's grains into the first distillation pot for distillation, and the distilled alcohol vapor is passed into the distillation tower, condensed and refluxed through the condenser group connected to the distillation tower;

[0030] Pass the distiller's grains after distillation in the first distillation kettle into the second distillation kettle for distillation again, and pass the distilled alcohol vapor into the first distillation kettle, and enter the distillation tower through the first distillation kettle;

[0031] If it is necessary to combine steamed grains during the distillation process, the distiller's grains from the second still will enter the third still to continue steaming until the wine and grains are steamed;

[0032] Pass part of the alcohol separated in the distillation tower into the first reboiler for evaporation, and pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com