Tester for simulating high-temperature corrosion in continuous distillation apparatus

A technology of test device and distillation device, applied in measurement device, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as inaccurate experimental results and inability to truly reflect corrosion problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

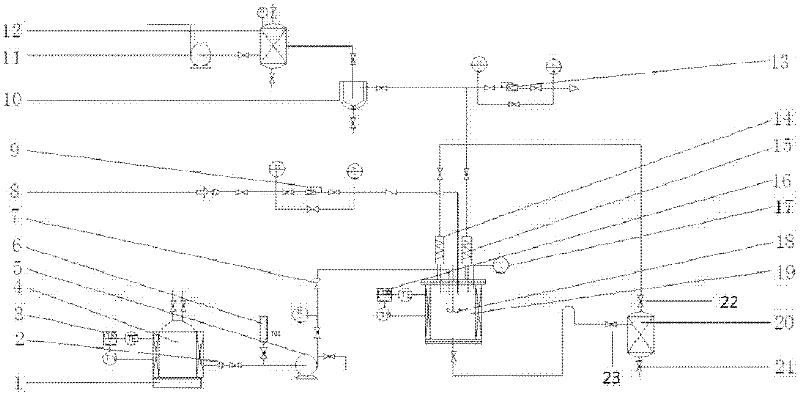

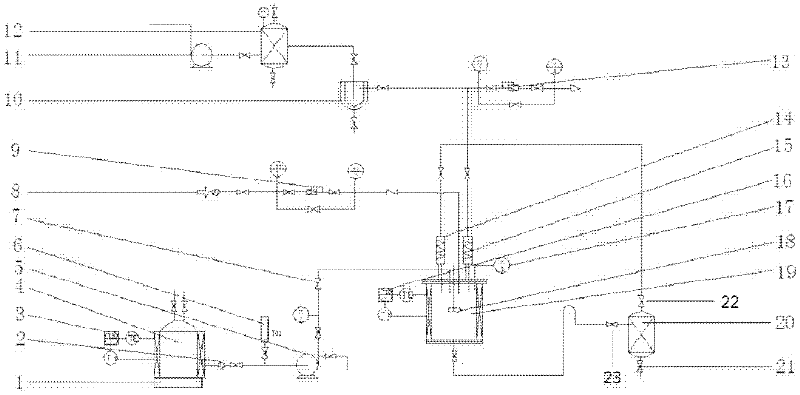

[0020] like figure 1 As shown, the device mainly includes a feed module, a kettle-type corrosion detection module, a vacuum and its control module, a temperature and pressure control module, a flow control module and other auxiliary modules. The feeding module includes an experimental oil raw material tank 4 with an electric heating jacket, which can be controlled to preheat to no more than 60°C. The raw material tank 4 is used to contain the medium used in the experiment, such as the crude oil after electric desalting or the bottom oil of the atmospheric distillation tower. An electronic scale 1 is installed below the raw material tank 4, which can weigh the weight of the feed crude oil, and adjust the feed amount of crude oil according to the weight. The electric heating mantle outside the raw material tank 4 (not an innovative point in the present invention, so it is not marked in the figure) is used to heat the experimental medium in the raw material tank 4, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com