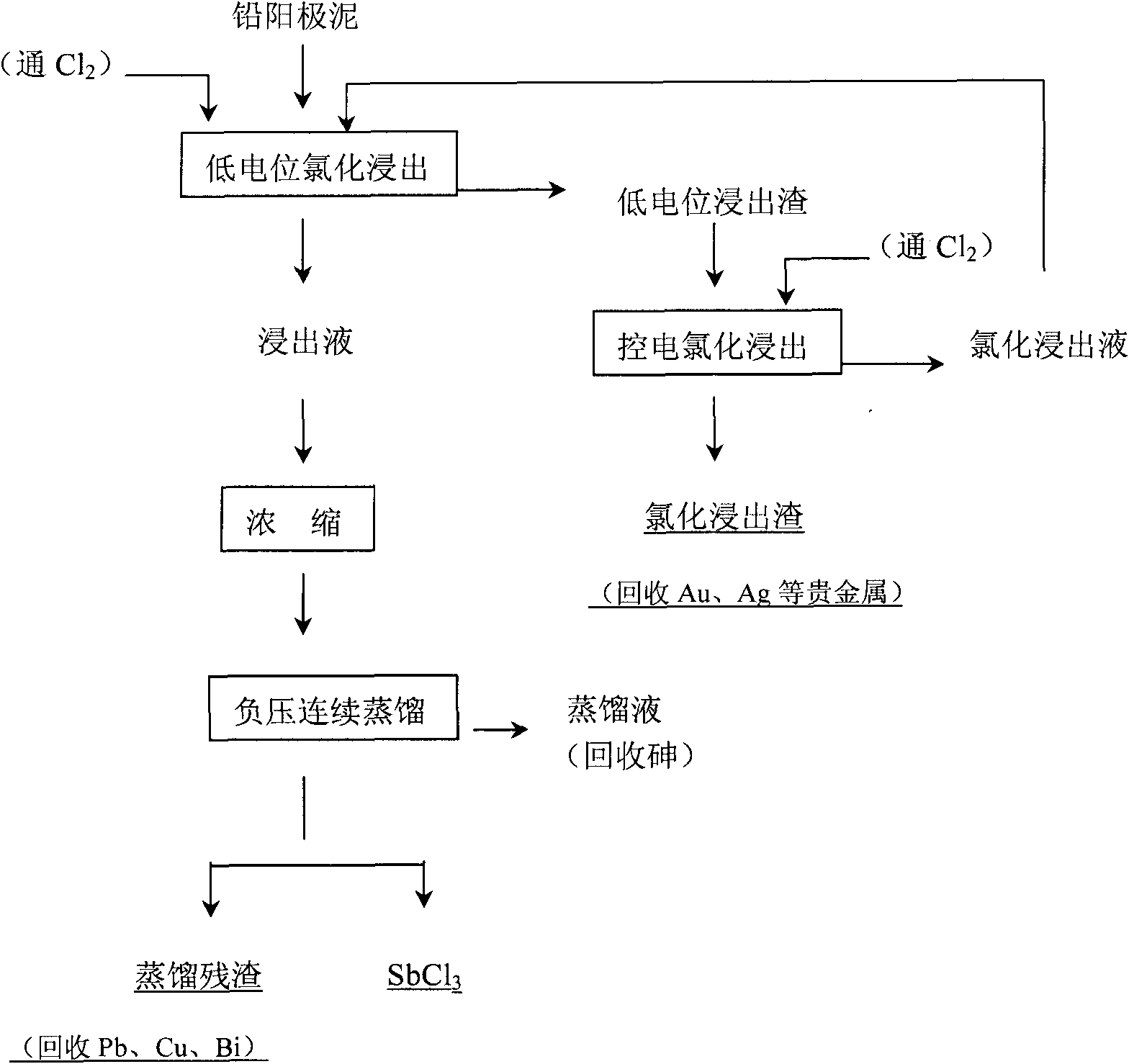

Method for wet processing of high antimony-lead anode mud

A technology of wet treatment and anode slime, which is applied in the direction of chemical instruments and methods, antimony compounds, process efficiency improvement, etc., can solve the problems of incomplete treatment, achieve low production cost, high direct antimony recovery rate, and benefit the environment The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] With content being (wt%): Sb70.52, Ag0.722, Pb11.72, As1.13, Bi1.78, the high antimony lead anode slime of Cu1.02, press the high antimony lead anode slime in 8M hydrochloric acid medium The degree of oxidation and the liquid-solid ratio required by the concentration of 400g / l Sb in the leaching solution are used to carry out one-stage chlorination leaching through chlorine, and the oxidation-reduction potential at the end point of the first-stage chlorination leaching is controlled at 200mv for 3 hours, and there is no pentavalent antimony ion in the first-stage chlorination leaching solution Standard: the first-stage chlorination leaching residue is passed through chlorine in 2M hydrochloric acid medium for second-stage chlorination leaching, and the oxidation-reduction potential at the end point of the second-stage chlorination leaching is controlled at 400mv for 3 hours, and the second-stage chlorination leaching solution is returned to the next batch of first-stage c...

Embodiment 2

[0026] The content is (wt%): Sb63.6, Ag1.08, Pb12.64, As4.04, Bi3.31, the high antimony lead anode slime of Cu1.47, press the high antimony lead anode slime in 12M hydrochloric acid medium The degree of oxidation and the liquid-solid ratio required by the concentration of 500g / lSb in the leachate are used to carry out one-stage chlorination leaching with chlorine, and the oxidation-reduction potential at the end point of the first-stage chlorination leaching is controlled at 300mv for 3 hours. The standard is that there is no pentavalent antimony ion in the first-stage chlorination leachate. The first stage of chlorination leaching slag is passed through chlorine in 4M hydrochloric acid medium to carry out second stage chlorination leaching, and the oxidation-reduction potential of the end point of the second stage chlorination leaching is controlled at 450mv for leaching for 3 hours, and the second stage chlorination leaching solution is returned to the next batch of one stage ...

Embodiment 3

[0029] With the high antimony lead anode slime described in Example 2, in 10M hydrochloric acid medium, according to the oxidation degree of high antimony lead anode slime and the liquid-solid ratio of leaching solution 500g / L Sb concentration requirement, carry out one stage of chlorine chlorination leaching, control one stage chlorine The oxidation-reduction potential at the end point of the chemical leaching is leached at 280mv for 3 hours, based on the absence of pentavalent antimony ions in the first-stage chlorinated leaching solution; The oxidation-reduction potential of the end point of chlorination leaching is leaching at 400mv for 3 hours, and the second-stage chlorination leaching solution is returned to the next batch of first-stage chlorination leaching, and 99.3% of gold and 99% of silver are enriched in the second-stage chlorination leaching residue.

[0030] Concentrate the chlorinated leaching solution with the composition (g / l): Sb492.16, Ag0.43, Pb2.76, As31.55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com