Apparatus and method for treating a fluid

A technology for treating fluids and treatment areas, applied in chemical instruments and methods, spraying devices, spraying devices, etc., can solve problems such as increasing height and reducing maximum feed rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

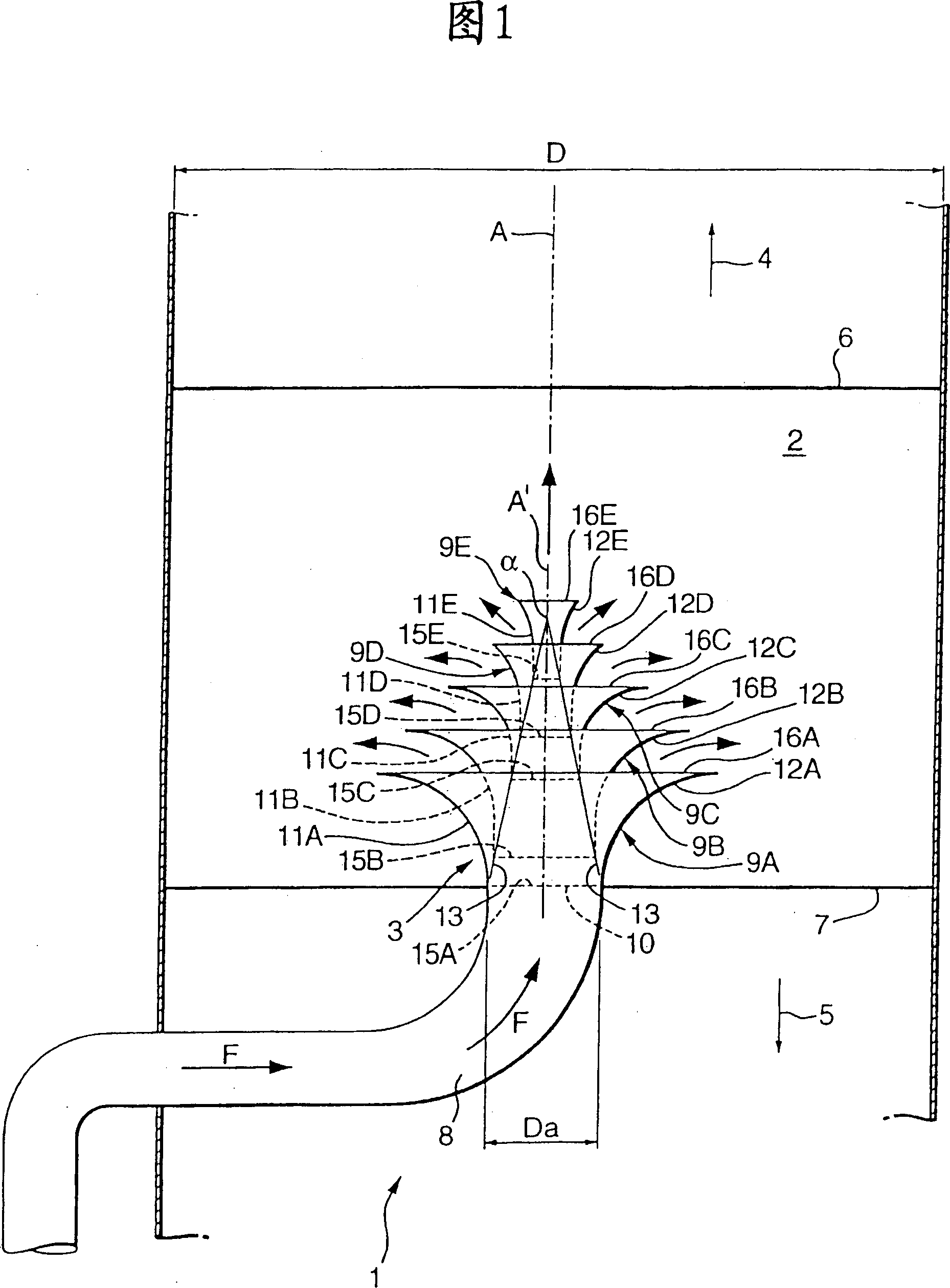

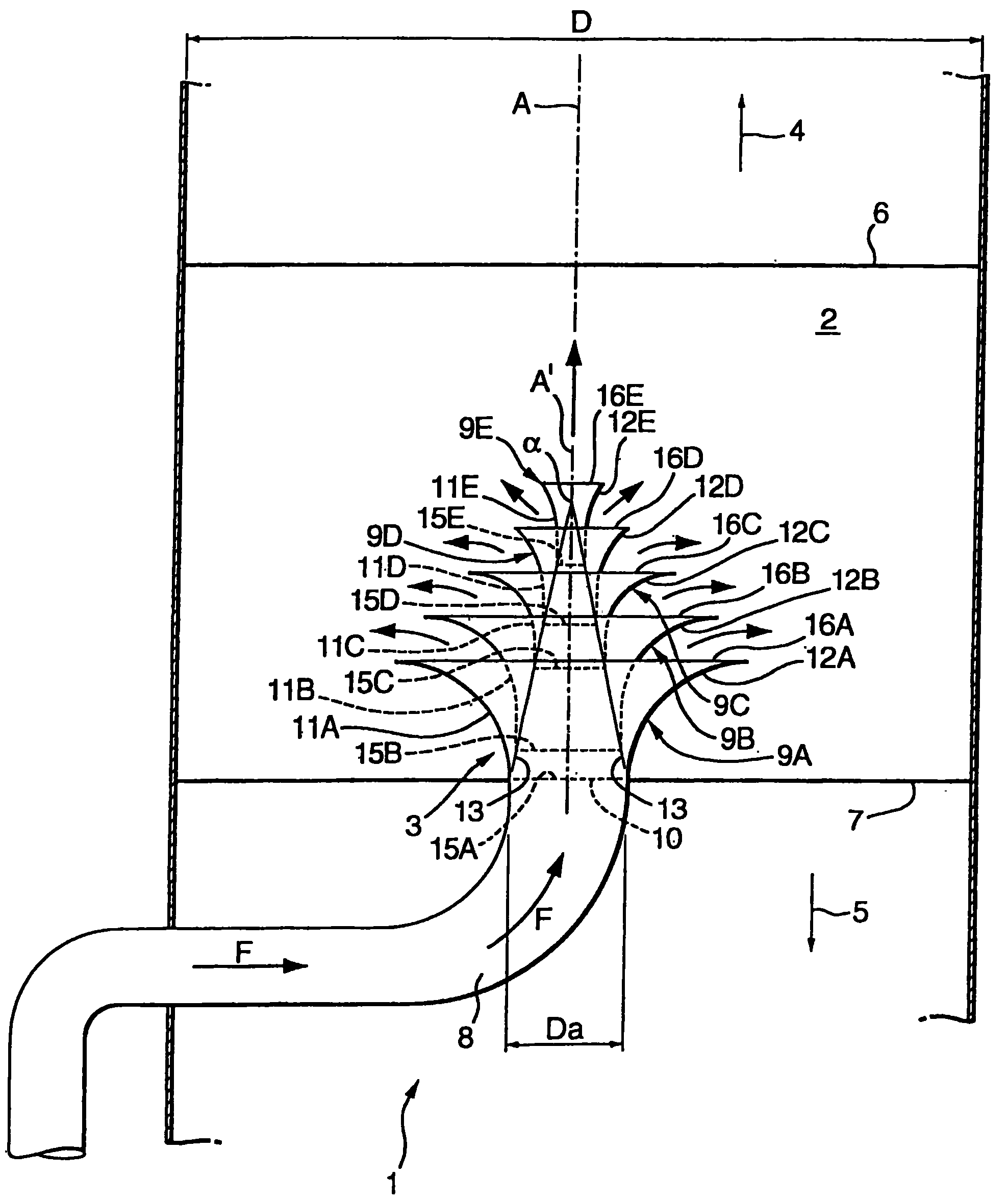

[0025] Referring to Figure 1, Figure 1 shows one section of a distillation column 1, which is typically used in a vertical orientation, as shown. The distillation column has a vertical longitudinal axis A and a substantially circular horizontal cross-section. The distillation column 1 comprises a first treatment zone 2 having an axis coincident with the axis A of the distillation column 1 and a fluid inlet arrangement 3 arranged in the treatment zone 2 . The first treatment zone 2 is arranged midway between the top and the bottom of the distillation tower 1. The top and bottom positions of the above-mentioned distillation tower 1 are represented by arrows 4 and 5 respectively, and the above-mentioned arrows 4 and 5 also represent passage through The corresponding upward gas flow and downward liquid flow of the above-mentioned distillation column.

[0026] The first treatment zone 2 is bounded in the direction of the top by a horizontally arranged gas treatment tray 6 and in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com