Distributor device for a column

a distribution device and column technology, applied in the direction of carburetor air, combustion air/fuel air treatment, separation process, etc., can solve the problems of inability to achieve uniform distribution of outlet apertures over the entire cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

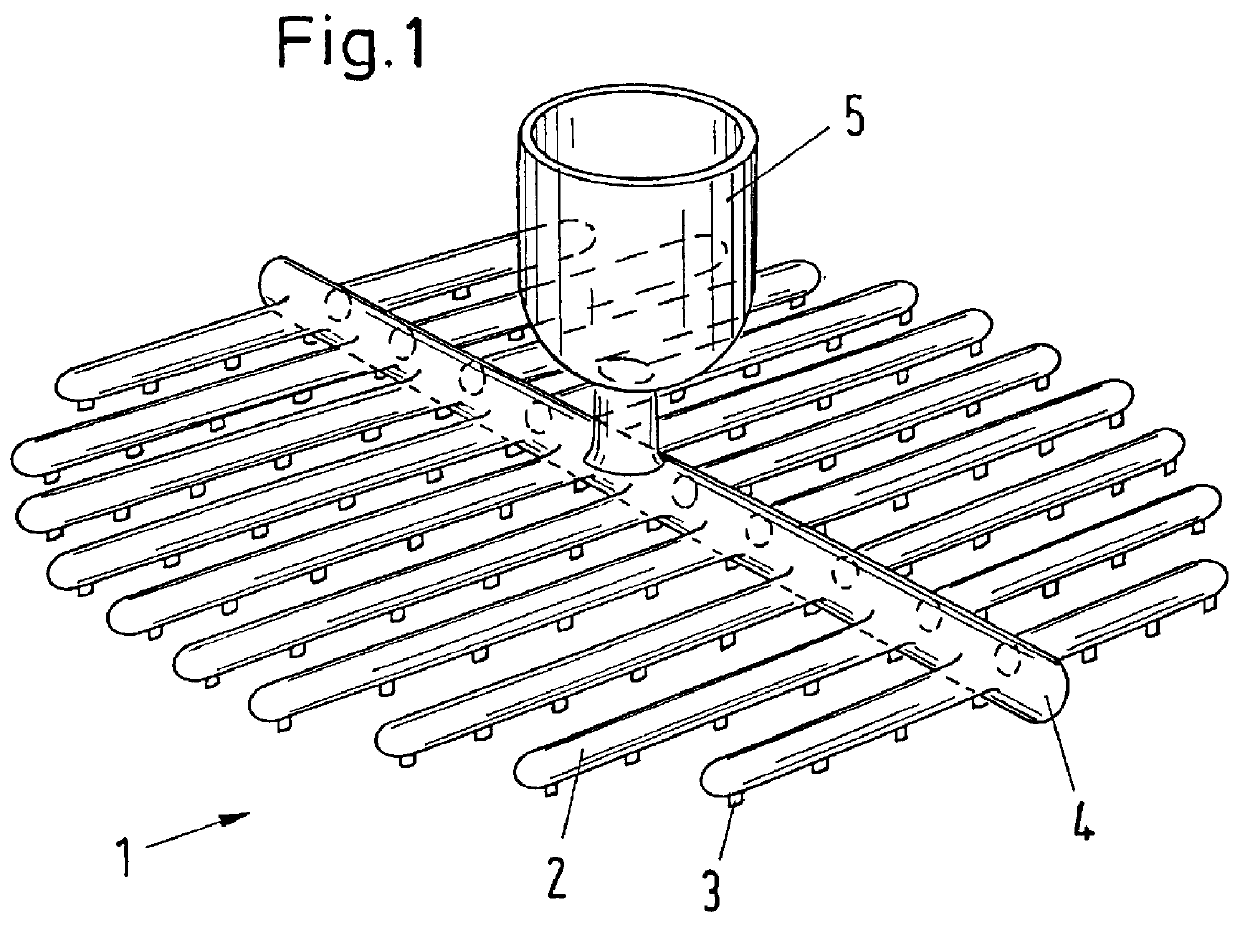

The distributor device 1 shown in FIG. 1 consists of glass and has the following construction: a plurality of distributor tubes 2 with nozzles 3 which, in accordance with the invention, are manufactured of glass tube pieces; an inlet tube 4 placed ahead of the tubes 2; and a bell or funnel 5 to which the liquid to be distributed can be supplied and in which the liquid collects up to a level depending on the outflow rate. The nozzles are all arranged at the same height so that the same outlet conditions result in each case.

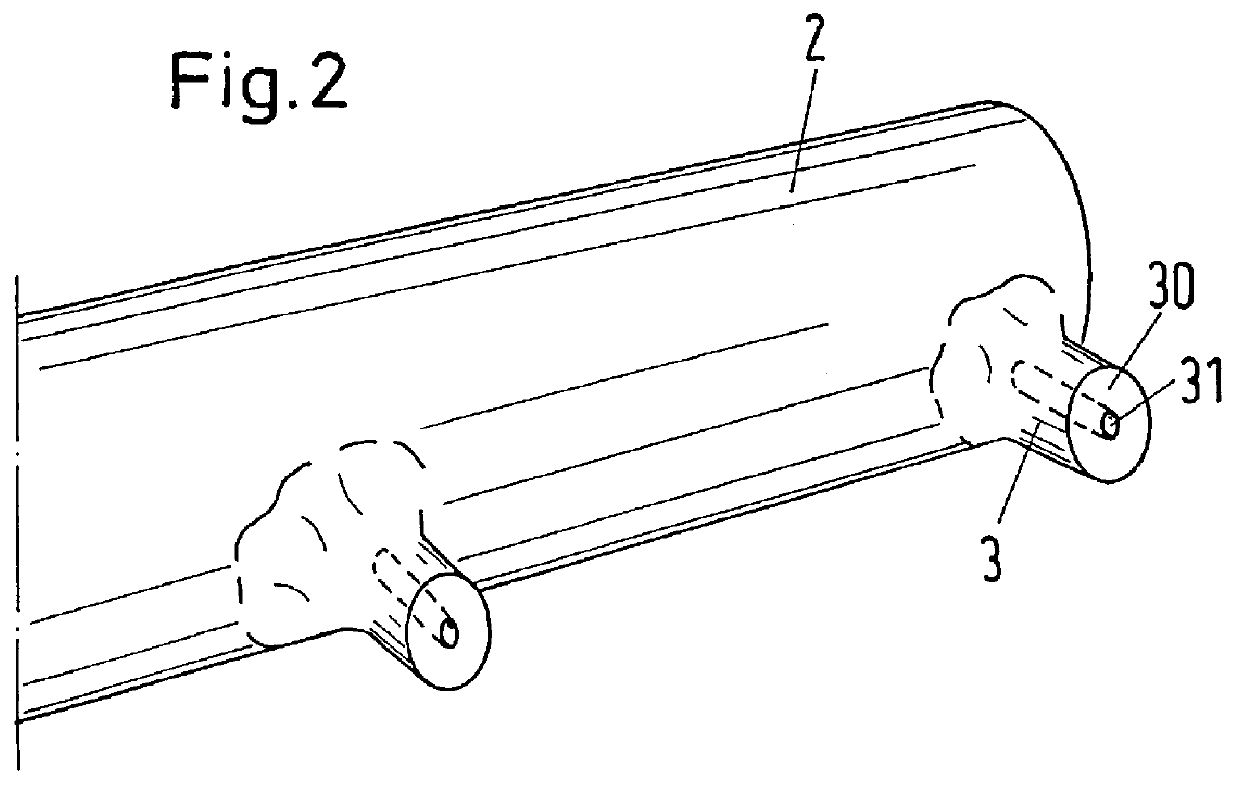

FIG. 2 shows a distributor tube 2 which is lying on its side and to which two glass tube pieces 3 serving as nozzles are attached by melting of the glass. The end face 30 of the tube piece 3 containing the outlet aperture 31 is an untreated mill-cut or broken glass surface. Thanks to this feature, the borders of the outlet apertures 31 are formed by edges produced by means of mill-cutting or glass breakage and are otherwise untreated. Practically the same outlet co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com