D-shaped tube for header

a header and d-shaped technology, applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of premature failure of the exhaust manifold assembly, high exhaust gas temperature at the manifold, and high stress on the manifold pipe, so as to reduce the turbulence of the cooling water flow, improve heat transfer, and reduce the effect of turbulen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] As discussed in the Summary of the Invention section, the present subject matter is particularly concerned with improved arrangements and methodology for providing water cooling for exhaust systems for internal combustion engines.

[0034] Selected combinations of aspects of the disclosed technology correspond to a plurality of different embodiments of the present subject matter. It should be noted that each of the exemplary embodiments presented and discussed herein should not insinuate limitations of the present subject matter. Features or steps illustrated or described as part of one embodiment may be used in combination with aspects of another embodiment to yield yet further embodiments. Additionally, certain features may be interchanged with similar devices or features not expressly mentioned which perform the same or similar functions.

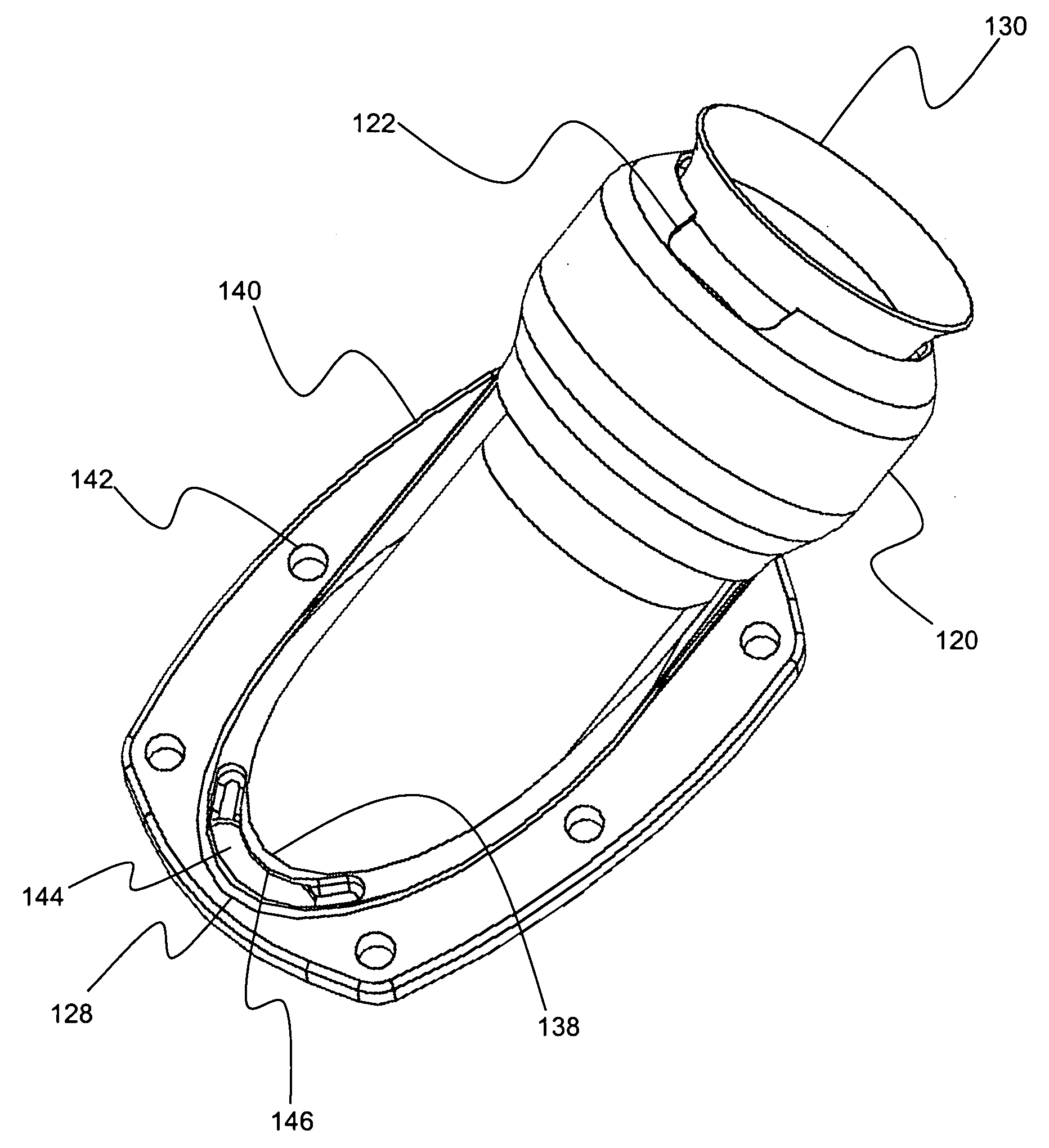

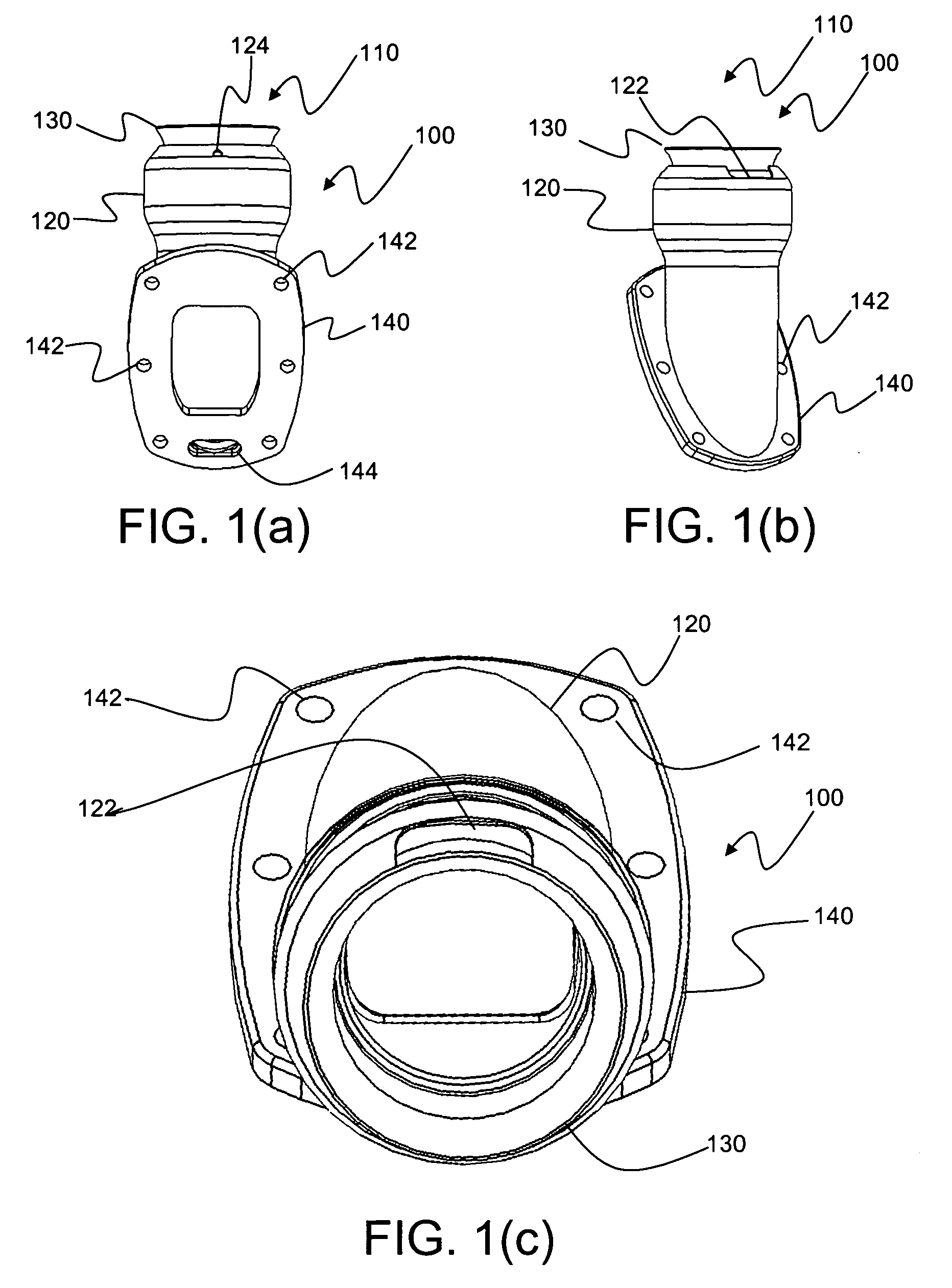

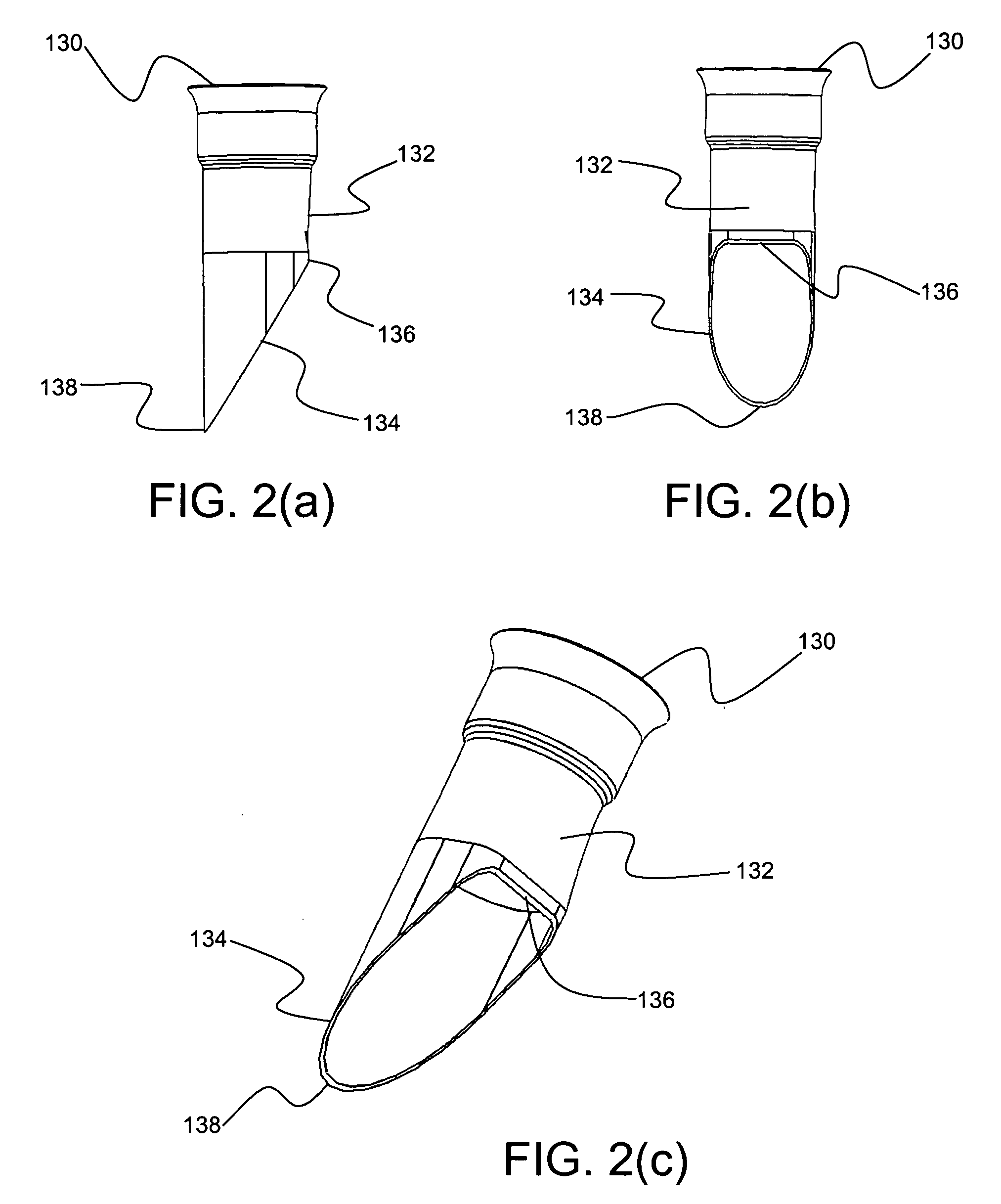

[0035] Reference will now be made in detail to the presently preferred embodiments of the subject water cooled exhaust system. Referring n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com