A diamond particle reinforced aluminum-based brake wear-resistant composite material and its preparation method

A technology of diamond particles and composite materials, which is applied in the field of diamond particle-reinforced aluminum-based composite materials for brake wear-resistant parts and its preparation, can solve the problem that the core function is not clearly explained and explained, and the diamond particles cannot play the enhancement phase design function. , It is difficult to obtain the problems of two-phase combination and interface morphology, so as to eliminate defects, reduce forming pressure and flow disturbance, and optimize the interface stress state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Diamond particle reinforced aluminum matrix composite "hat-shaped" brake disc components for passenger cars.

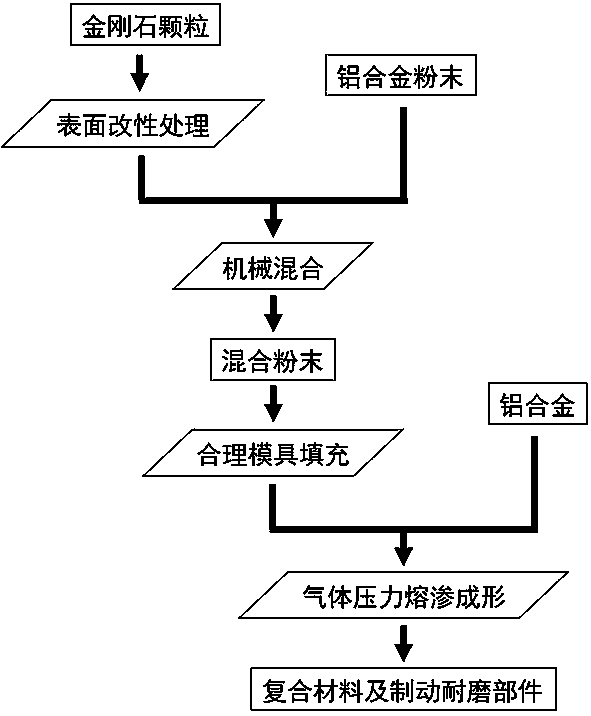

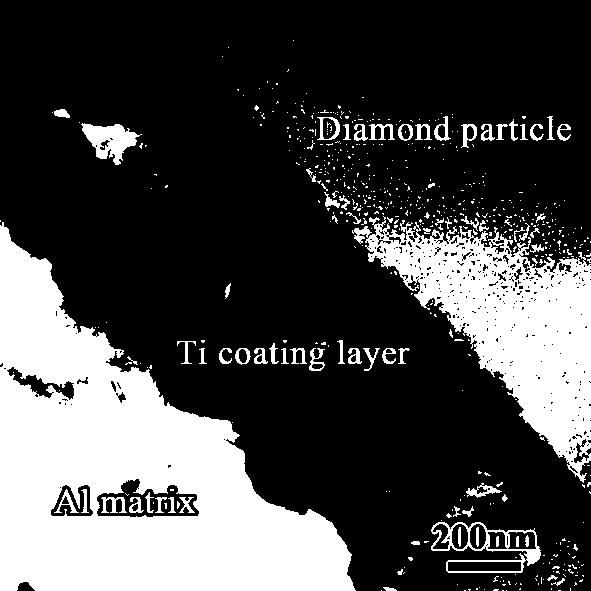

[0020] 15 μm diamond particles and 50 μm titanium powder were selected to be fully mixed with chloride salt at a molar ratio of 20:1, and then kept at 800°C for 30 minutes in a salt bath to obtain surface metallized diamond particles; the obtained titanium-coated diamond particles were mixed with 25 μm Al-2wt.% Cu alloy powder is mechanically mixed in a protective atmosphere at a volume ratio of 3:1, the mixed powder is filled in a graphite abrasive tool and ultrasonically vibrated; the whole mold is placed in a forming device, when the vacuum degree is less than 0.1Pa Heating, quickly filling argon gas at 850°C and pressurizing to 0.8Mpa, driving Al-7wt.% Si alloy infiltration forming, heat preservation and pressure holding for 10 minutes, cooling with the furnace and demoulding treatment, to obtain a near-final formed composite Material Brake disc blanks. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com