An inlet and outlet tube box for evenly distributing the flow in the tube of a tube heat exchanger

A tubular heat exchanger, evenly distributed technology, applied in the direction of heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., to achieve the effect of increasing the flow area and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0038] The invention is an inlet and outlet pipe box for evenly distributing the flow in the tube of a tubular heat exchanger, which can realize the uniform distribution of the flow of the heat exchange working medium in the heat exchange tube bundle, reduce the deviation of the flow in the tube, and reduce the flow caused by the flow of the working medium in the heat exchange tube. Uneven distribution has an adverse effect on the overall heat transfer efficiency of the heat exchanger. It is used in tube flue gas heat exchange devices in thermal power plants and related industrial processes, and can also be used for uniform distribution of working fluid flow in tube bundles of compact tube heat exchangers.

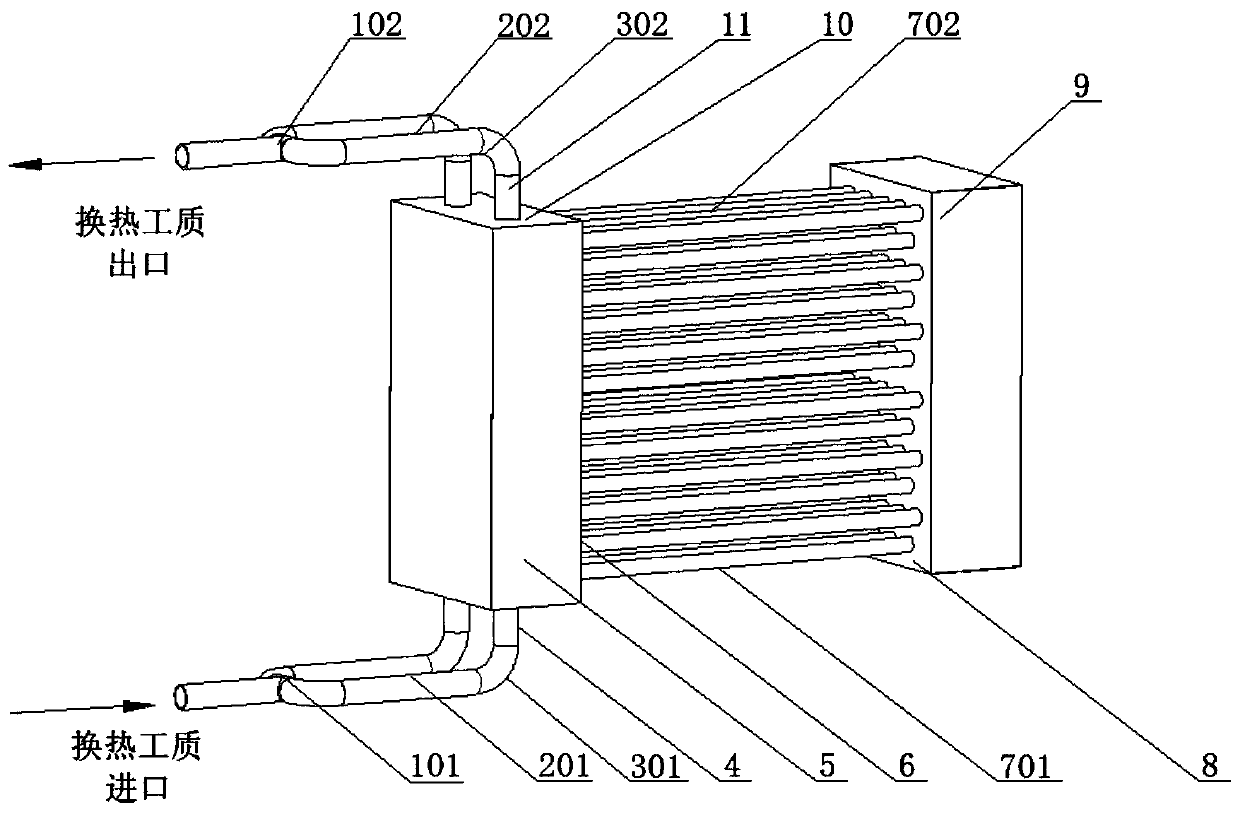

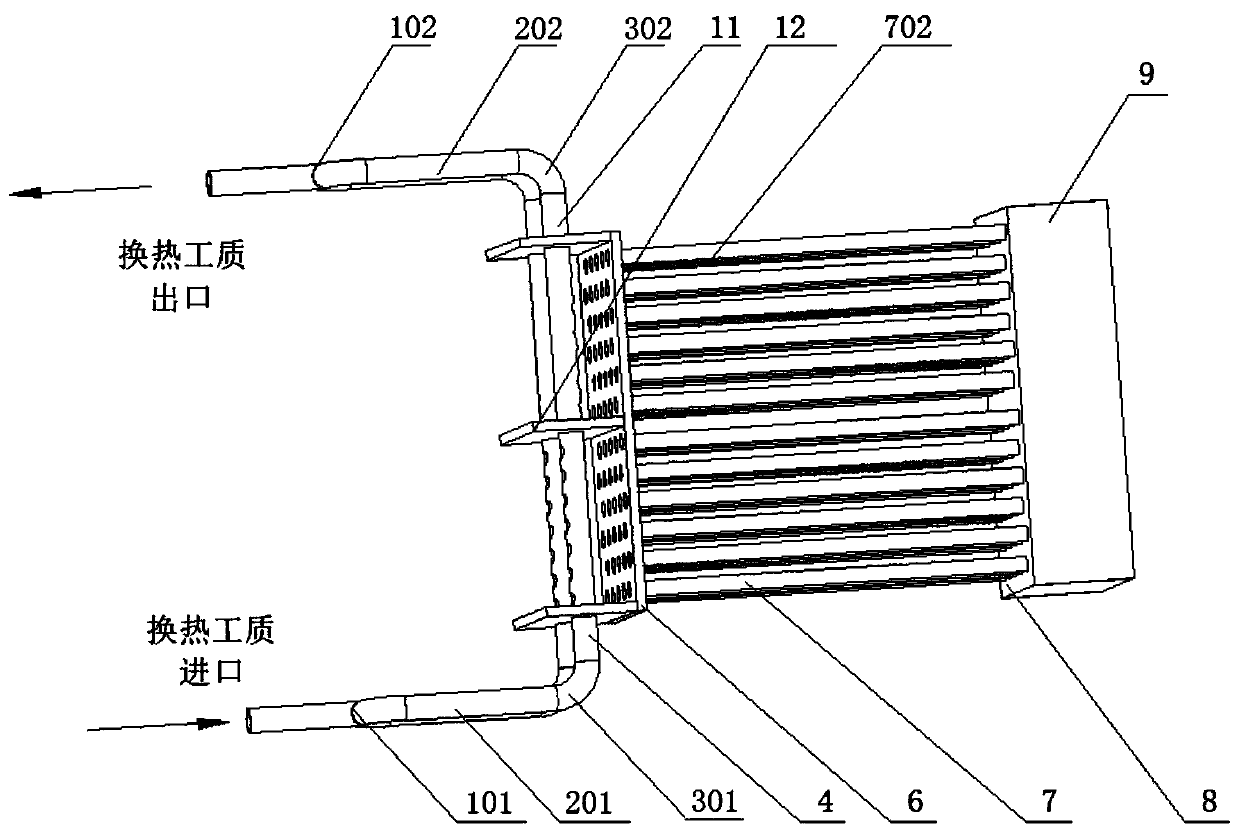

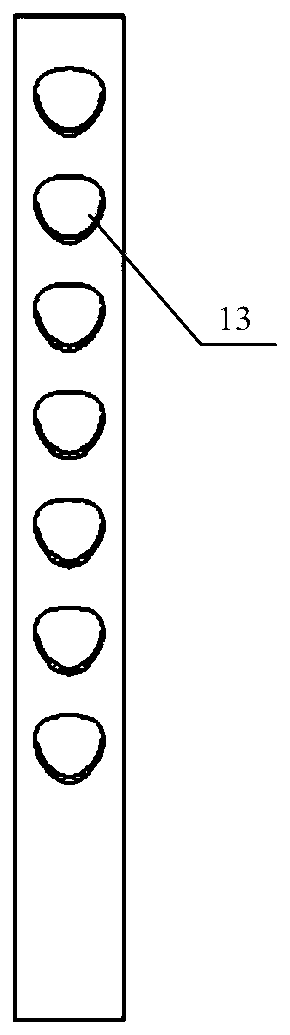

[0039] Such as figure 1 As shown, the present invention is an inlet and outlet tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com