Method for preparing aluminum alloy engine cylinder cover by using tilted pouring process

An engine cylinder head, aluminum alloy technology, applied in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve the problems of high scrap rate and low process yield, solve shrinkage porosity problem, improve sequential solidification, avoid Effects of entrainment and loss of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

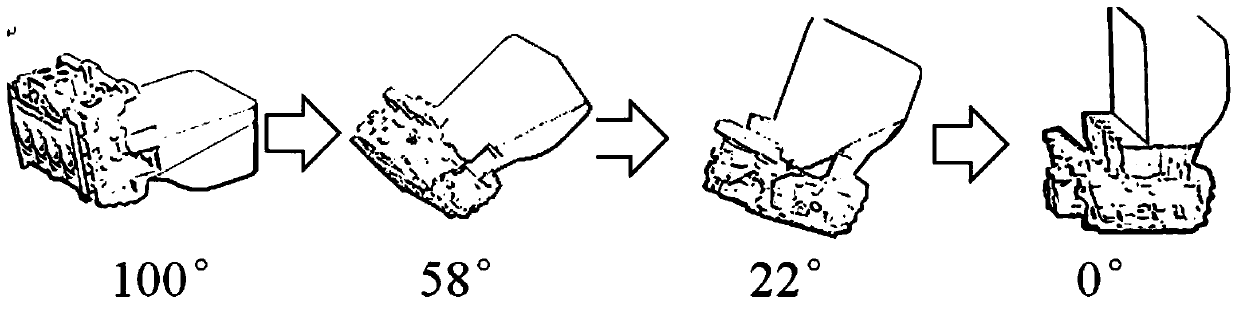

[0032] Since the aluminum alloy engine cylinder head is a thin-walled complex part, with many sand cores and high dimensional accuracy requirements, gravity casting can only be used. The traditional top casting, bottom casting and middle casting cannot meet the casting requirements of this cylinder head. Therefore, only the tilting pouring belongs to the category of gravity casting pouring can be studied and applied to this cylinder head to achieve the development purpose and quality requirements.

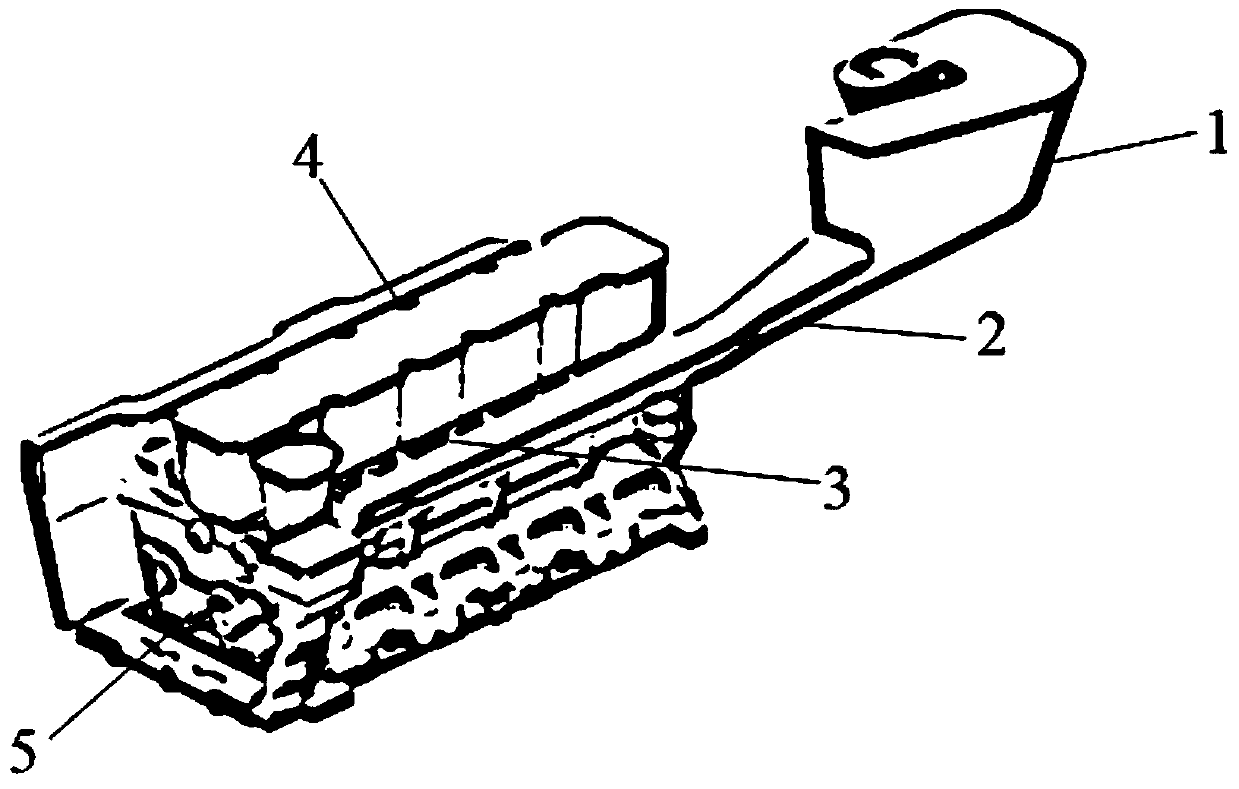

[0033] The pouring process of the original aluminum alloy cylinder head, refer to figure 1 , in the figure:

[0034] The aluminum water flows in from the sprue cup 1, flows into the riser A4 and the cylinder head cavity A5 through the sprue 2 and the ingate A3, and the aluminum water in the cylinder head cavity A5 forms an aluminum alloy engine cylinder head, and the riser A4 The aluminum water in the cylinder head cavity A5 feeds the aluminum water.

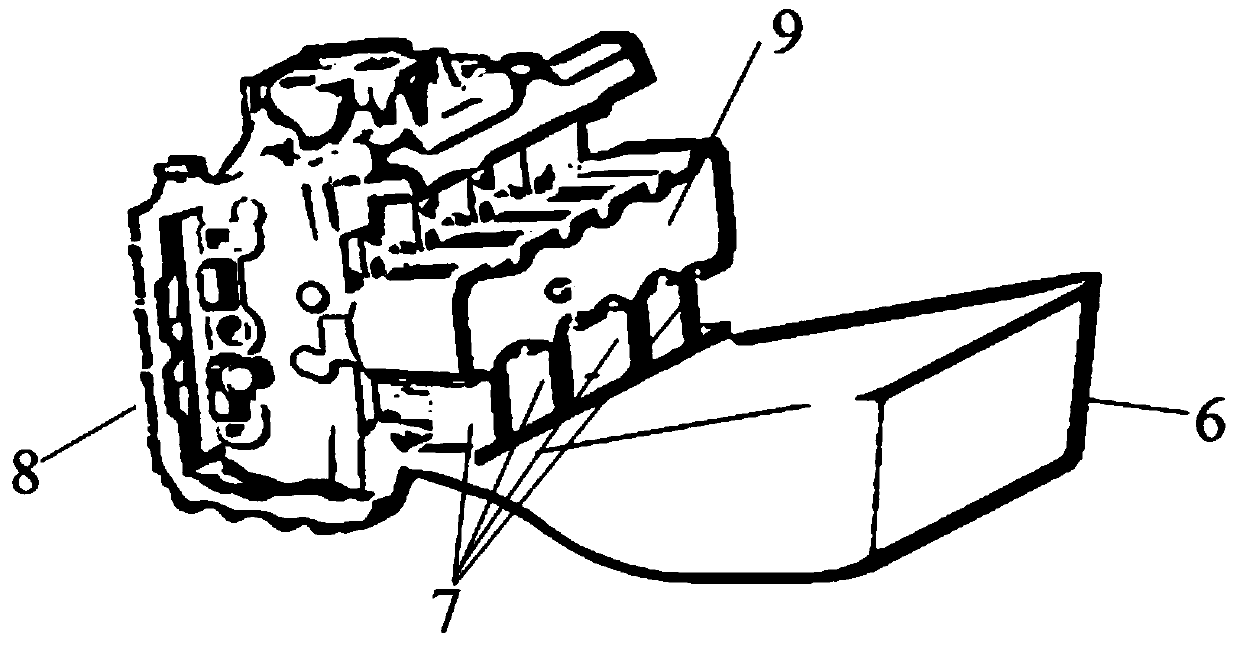

[0035] The tilting pouring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com