Multi-parameter mine spraying heat exchange efficiency calculation method-based spraying system

A technology of heat exchange efficiency and calculation method, which is applied in the field of sprinkler systems, and can solve the problems of constant number of sprinklers and waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described below in conjunction with the accompanying drawings.

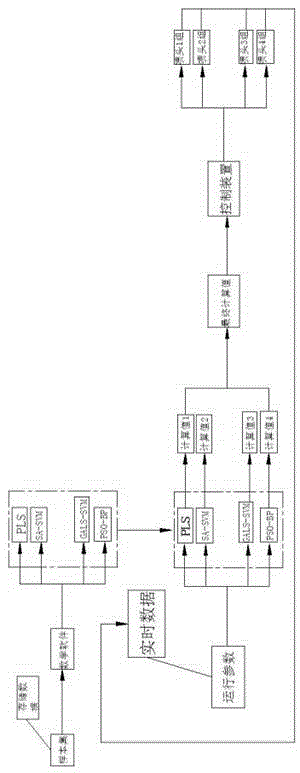

[0098] Depend on figure 1 , collect and classify the operating parameters of the spray heat exchange system: in order to ensure that the trained model has better adaptability in subsequent predictions, the collected parameter data should be classified according to the different performance levels of the desulfurization system, that is, high efficiency Performance level, efficiency is between [1, 0.95]; general efficiency performance level, efficiency is between (0.95, 0.85]; low efficiency performance level, efficiency is below 0.85. Take at least 500 in each of the three performance level segments group data as training samples.

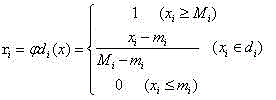

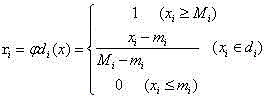

[0099] (2) Normalize the operating parameters: set the heat transfer efficiency The domain of discourse is Assume , is the model pair property value the dimensionless value of , and .

[0100]

[0101] in, for The standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com