Method for removing acidic components and water from gas in one step

A technology for acid components and gases, applied in the field of one-step removal of acid components and water, can solve problems such as the combination of deacidification and dehydration processes, and achieve the effects of increasing surface area, reducing purification costs, and avoiding degradation and deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

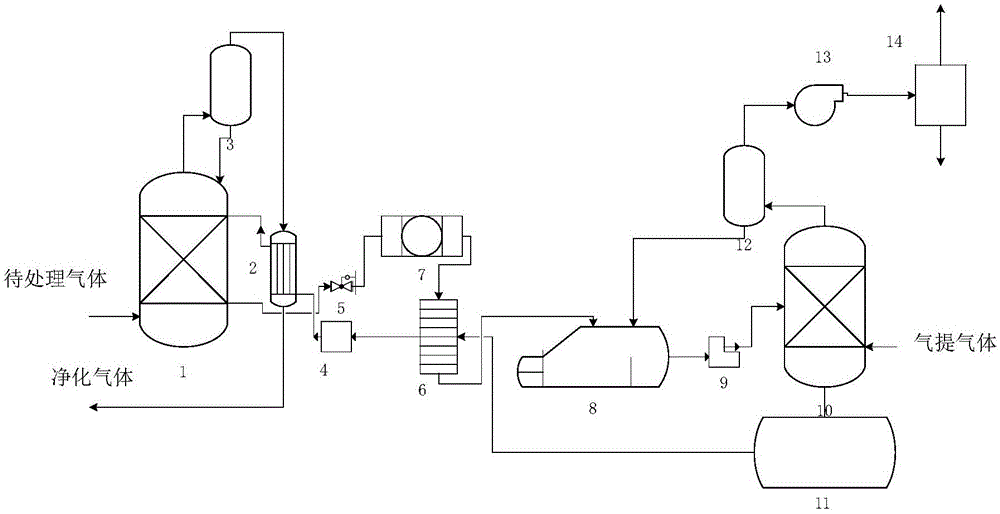

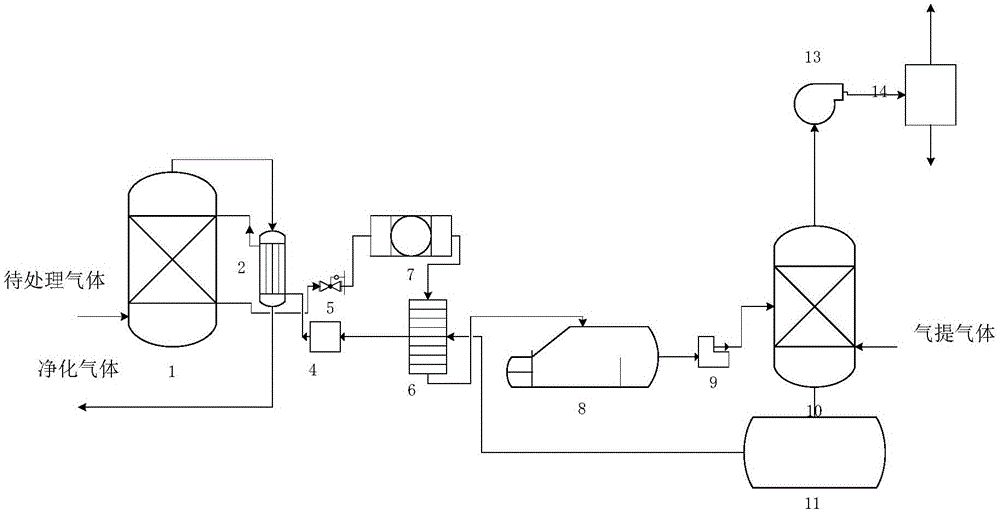

[0046] According to a specific embodiment of the present invention, the method for removing acid components and water in one step from gas is figure 1Or in the one-step deacidification and dehydration system shown in 2, the one-step deacidification and dehydration system includes an absorption device and a regeneration device, wherein the regeneration device includes a heater 8 and a supergravity regenerator 10. The gas to be treated containing acidic components and water is contacted with an absorbent in the supergravity absorber 1 to remove the acidic components and water in the gas to be treated to obtain purified gas from which the acidic components and water have been removed And the rich absorbent that has absorbed acidic components and water, the purified gas is discharged from the gas outlet at the top of the supergravity absorber 1, and part of the absorbent entrained in the gas is recovered through the first recycler 3 or not, and the The rich absorbent is then decom...

Embodiment 1

[0051] This example is used to illustrate the one-step method for removing acidic components and water provided by the present invention.

[0052] Main components of the gas to be treated: water content 5g / m 3 , CO 2 Content 1.5% (v / v), H 2 S content 1% (v / v), the rest is methane;

[0053] Supergravity absorber: manufactured by Hangzhou Keli Chemical Equipment Co., Ltd., model BZ750-3P;

[0054] Supergravity regenerator: manufactured by Hangzhou Keli Chemical Equipment Co., Ltd., model BZ750-3P;

[0055] Absorption test: gas to be treated at 500Nm 3 The flow rate of / h is introduced into the high gravity absorber from the gas inlet of the high gravity absorber, and the absorbent (obtained after uniformly mixing 20 parts by weight of TEG and 80 parts by weight of MDEA) is fed from the supergravity absorber at a flow rate of 100kg / h The liquid inlet of the gravity absorber is introduced into the supergravity absorber, the rotation speed is 1000r / min, the absorption pressure...

Embodiment 2

[0060] This example is used to illustrate the one-step method for removing acidic components and water provided by the present invention.

[0061] The absorption test of this embodiment is the same as that of Example 1, except that the desorption test is carried out at 160° C., and other conditions remain unchanged. Analysis of the water content in the lean absorbent was 0.1% by weight, the hydrogen sulfide content was 0.2% by weight, and no carbon dioxide was detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com