Method for preparing nano alumina

A technology of nano-alumina and aluminum nitrate, which is applied in the field of preparation of nano-alumina and high-gravity method to prepare nano-alumina, which can solve the problems of inability to achieve high purity and uneven particle size distribution of alumina, and achieve low cost and few varieties , simple process and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

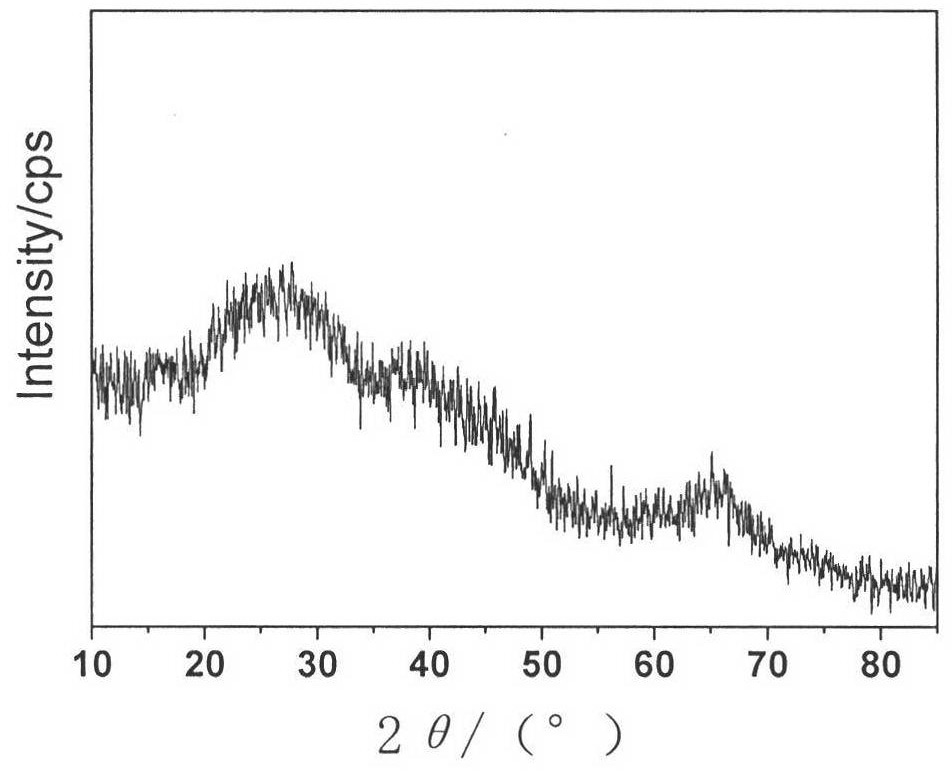

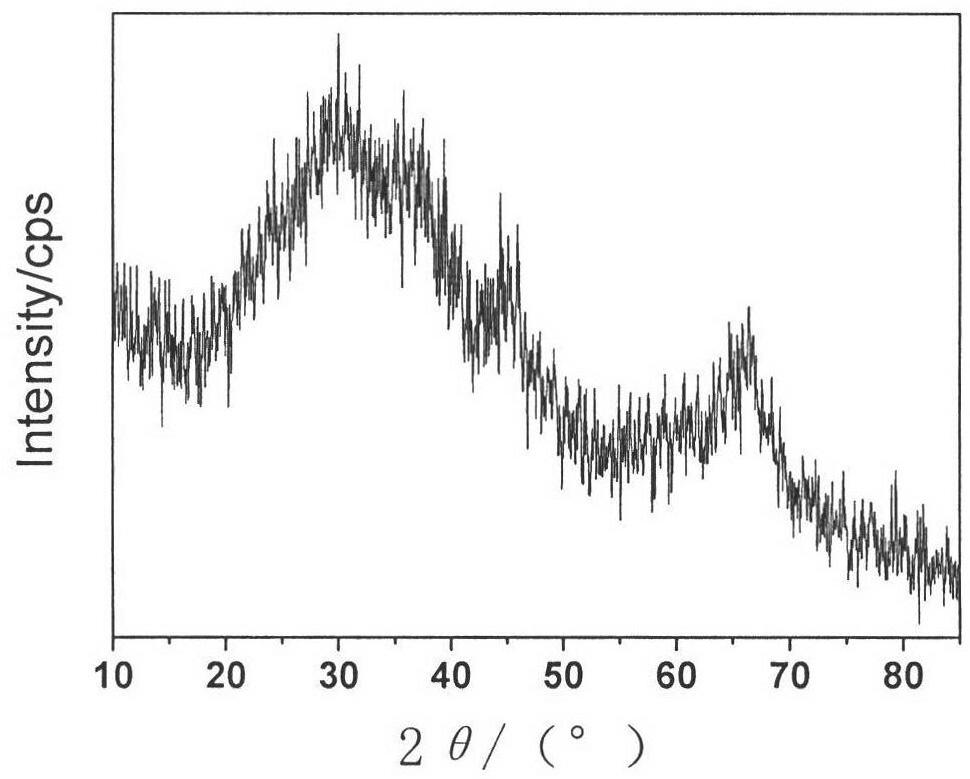

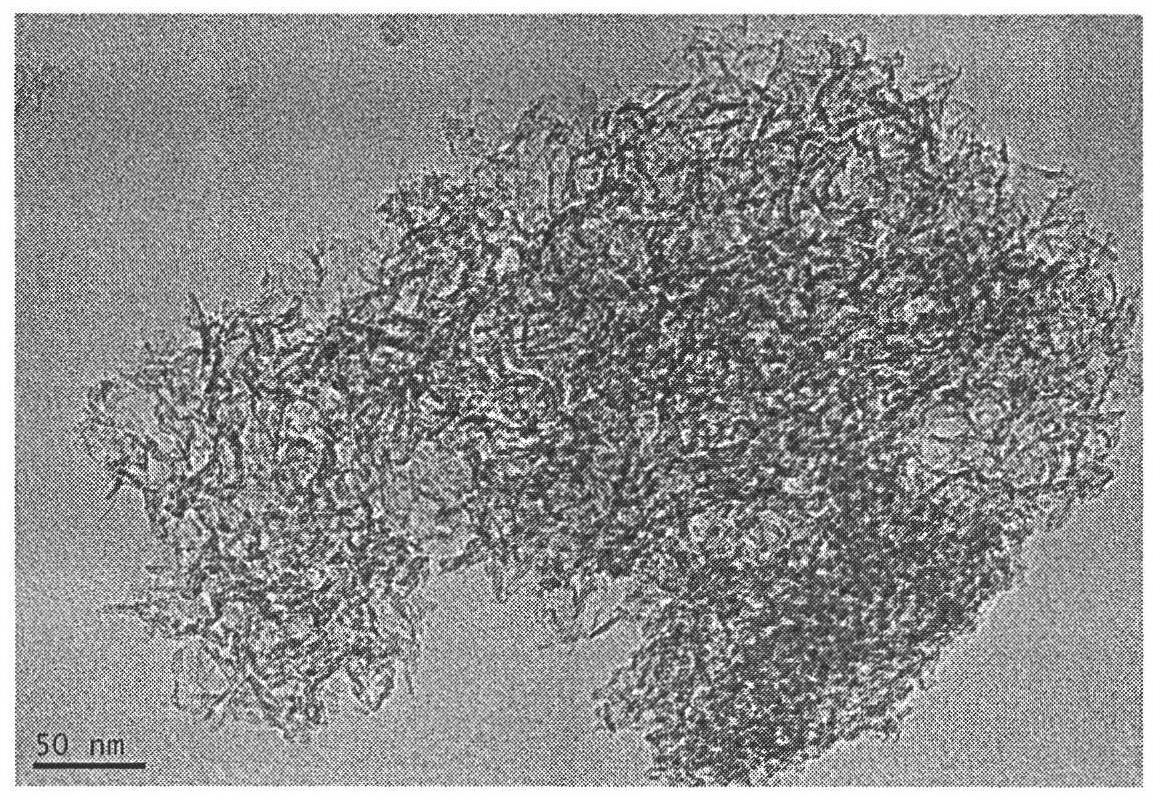

[0032] Add 150g of aluminum nitrate to 2L of water, add 68.4g of sucrose to obtain a solution with a concentration of 0.2mol / L of aluminum nitrate, the molar ratio of sucrose to aluminum nitrate is 0.5:1, stir until it is completely dissolved, and transfer to the spiral channel rotating bed for circulation , adjust the rotating speed to be 800rpm, and the circulation flow rate to be 350L / h, then add 5% ammonia solution dropwise to the solution until the pH=5.5 and stop the dropwise addition to form a sol. Transfer out the sol solution, place it in a water bath at 80°C for 2h, and then transfer it to a ventilated drying oven at 120°C for 36h to obtain a black-gray precursor XRD pattern as shown in figure 1 As shown, there is no obvious sucrose or NH in the figure 4 NO 3 Crystal phase diffraction peaks appeared, and the sucrose may have undergone a dehydration reaction during the gel combustion process and was preserved in the form of carbon elements. Sucrose (or its dehydrati...

Embodiment 2

[0034] Alumina was prepared in the same manner as in Example 1, except that the amount of sucrose added was 96.7g, the molar ratio of sucrose to aluminum nitrate was 0.7:1, the rotating speed was 1000rpm, and the temperature set during calcination was 1200°C. The resulting product is alpha-alumina.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com