A high-gravity rotating bed device with staged liquid feeding and enhanced rotor end effect

A technology of supergravity rotating bed and rotor end, applied in the field of supergravity rotating bed device and supergravity rotating packed bed, can solve the problems of increasing equipment space, underutilization of packing, affecting the stability of the device, etc. The effect of increased mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

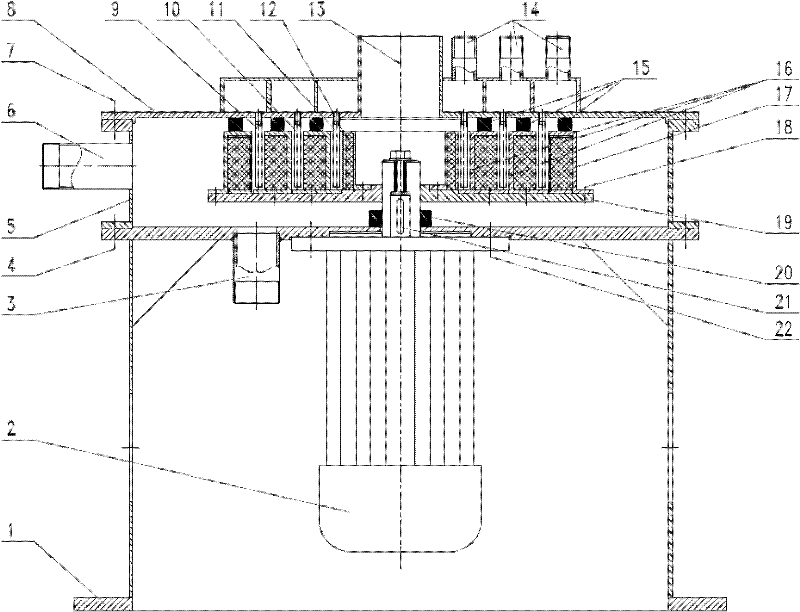

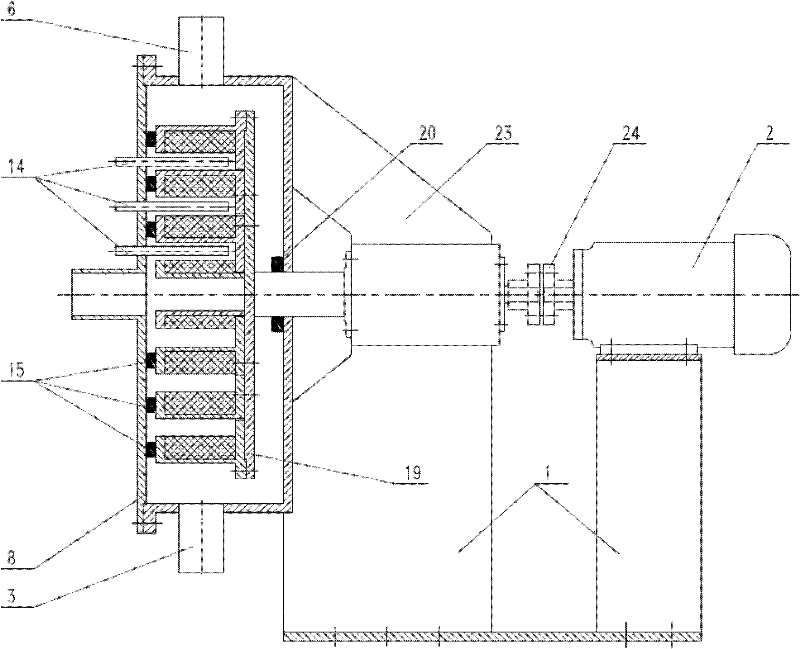

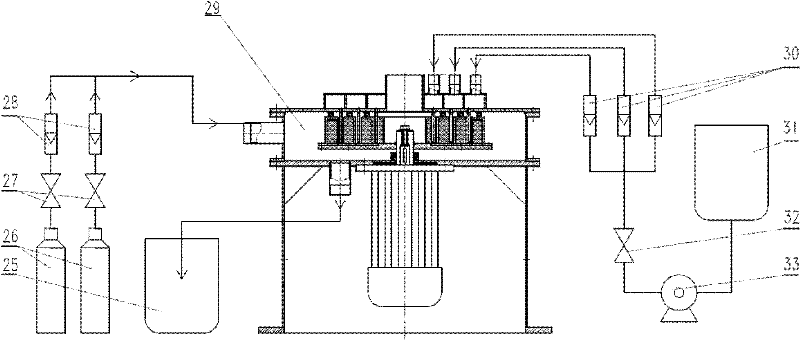

[0022] Such as figure 1In the vertical supergravity rotating bed device shown, in the airtight cavity 5, the shaft of the motor 2 and the turntable 20 are fixed together by bolts 22, and the motor 2 and the base 1 are fixed together by bolts. The shaft of the motor 2 transmits torque to the shaft of the turntable 19 through the key 21, so that the rotor fixed on the turntable 19 rotates. The rotating bed rotor includes a packing gland 16, a backsplash liquid capture device 12 (the liquid capture device is an annular hollow cylinder, and a filler with a radial thickness of about 5 mm is installed in the cylinder ring. The liquid capture device is connected to the turntable by bolts, Rotate at the same speed as the turntable), packing 17, turntable 19 and bolt 18. The upper end of the rotary bed cavity gland 8 is welded with three separate annular liquid inlet chambers, and the lower end is connected with the first liquid inlet spray pipe 11, the second liquid inlet spray pipe ...

Embodiment 2-25

[0027] The process flow and steps are the same as in Example 1, and the process conditions and operating conditions of each embodiment and the corresponding experimental results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial thickness | aaaaa | aaaaa |

| Radial thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com