Supergravity revolving bed device and application in carbon dioxide collecting and passivating process

A technology of carbon dioxide and rotating bed, which is applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc. It can solve problems such as low gas-liquid ratio, large amount of liquid, and large thickness of packing layer, etc., to achieve Improve the efficiency of trapping and purification, reduce operating costs, and enhance the effect of gas-liquid mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

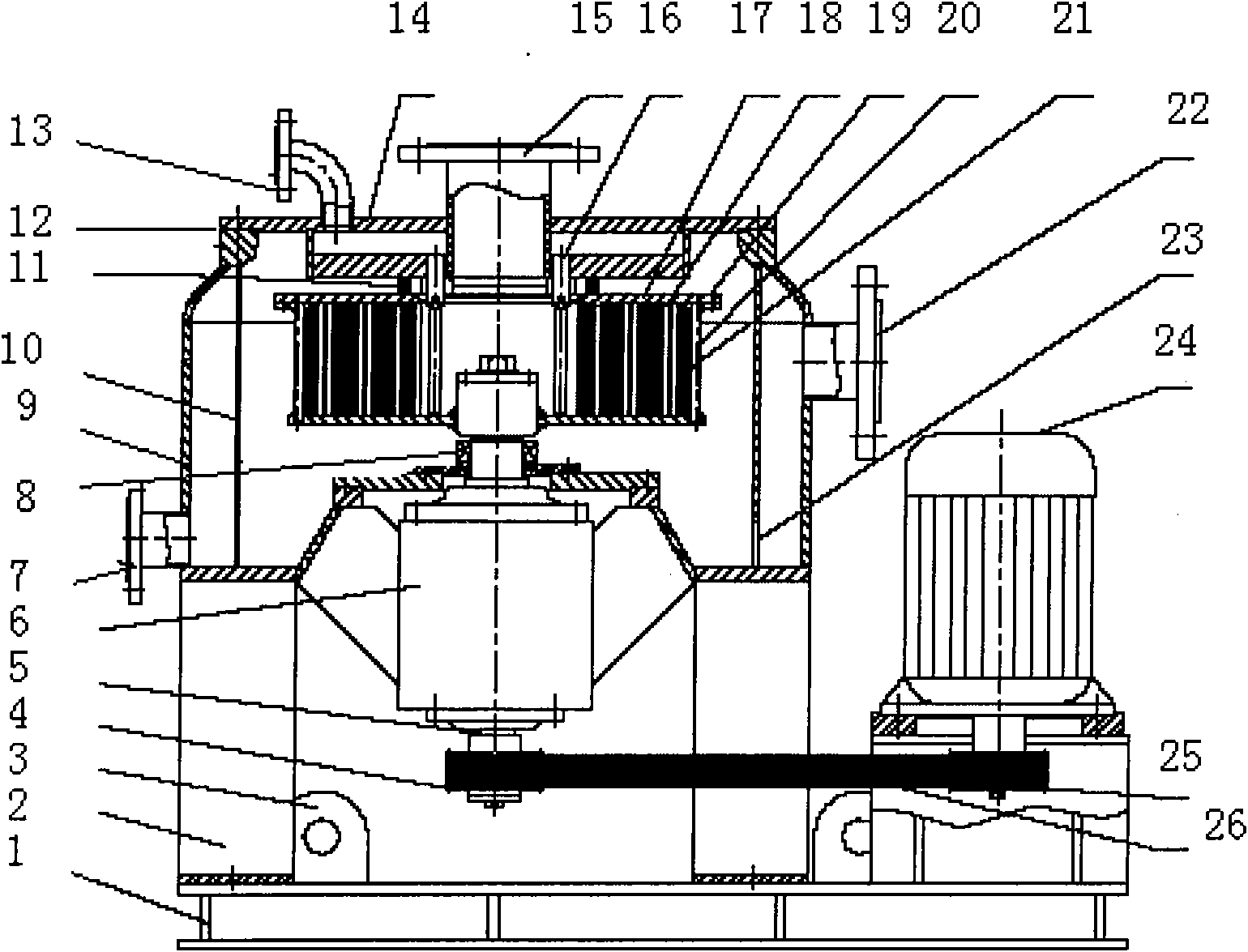

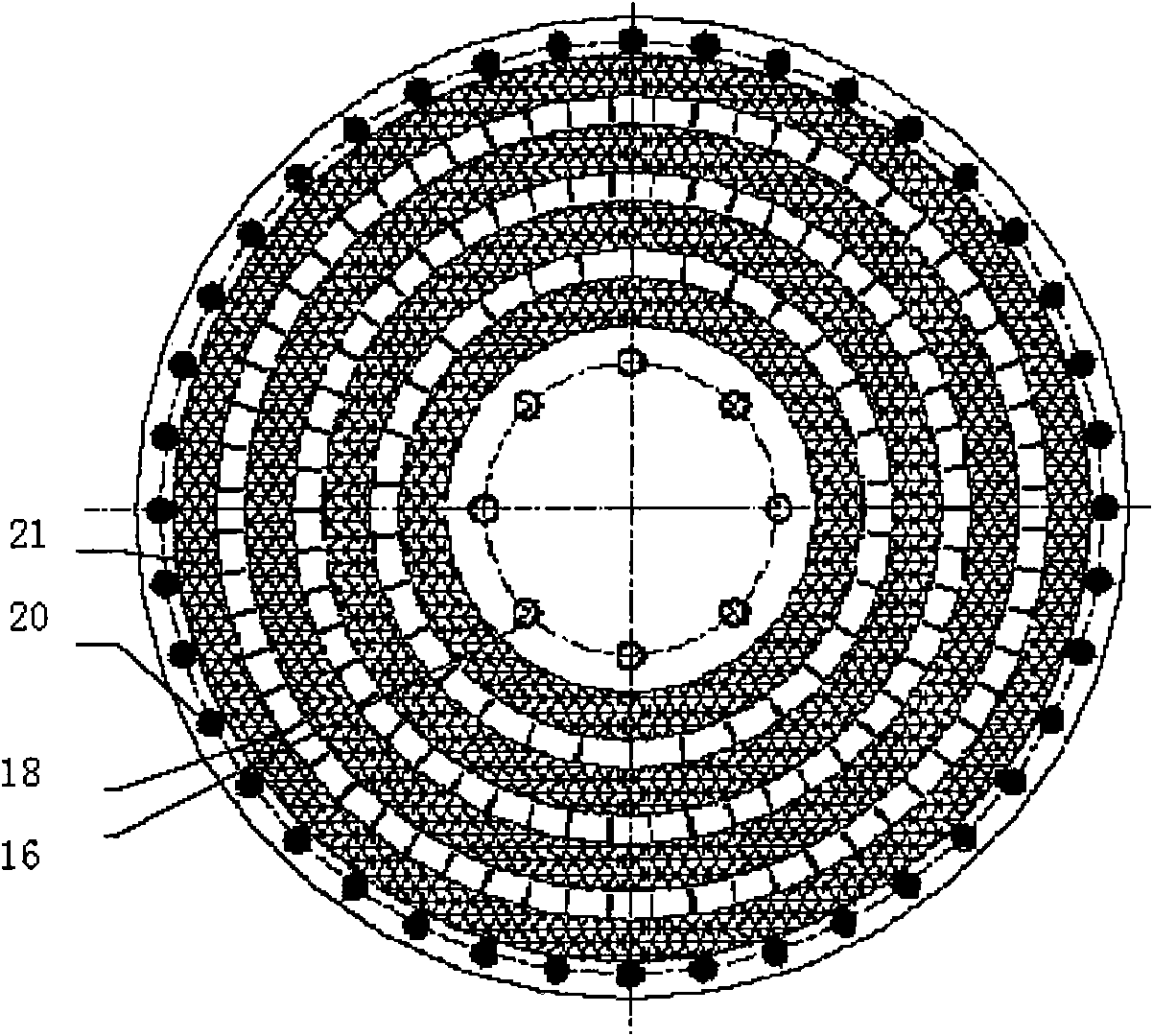

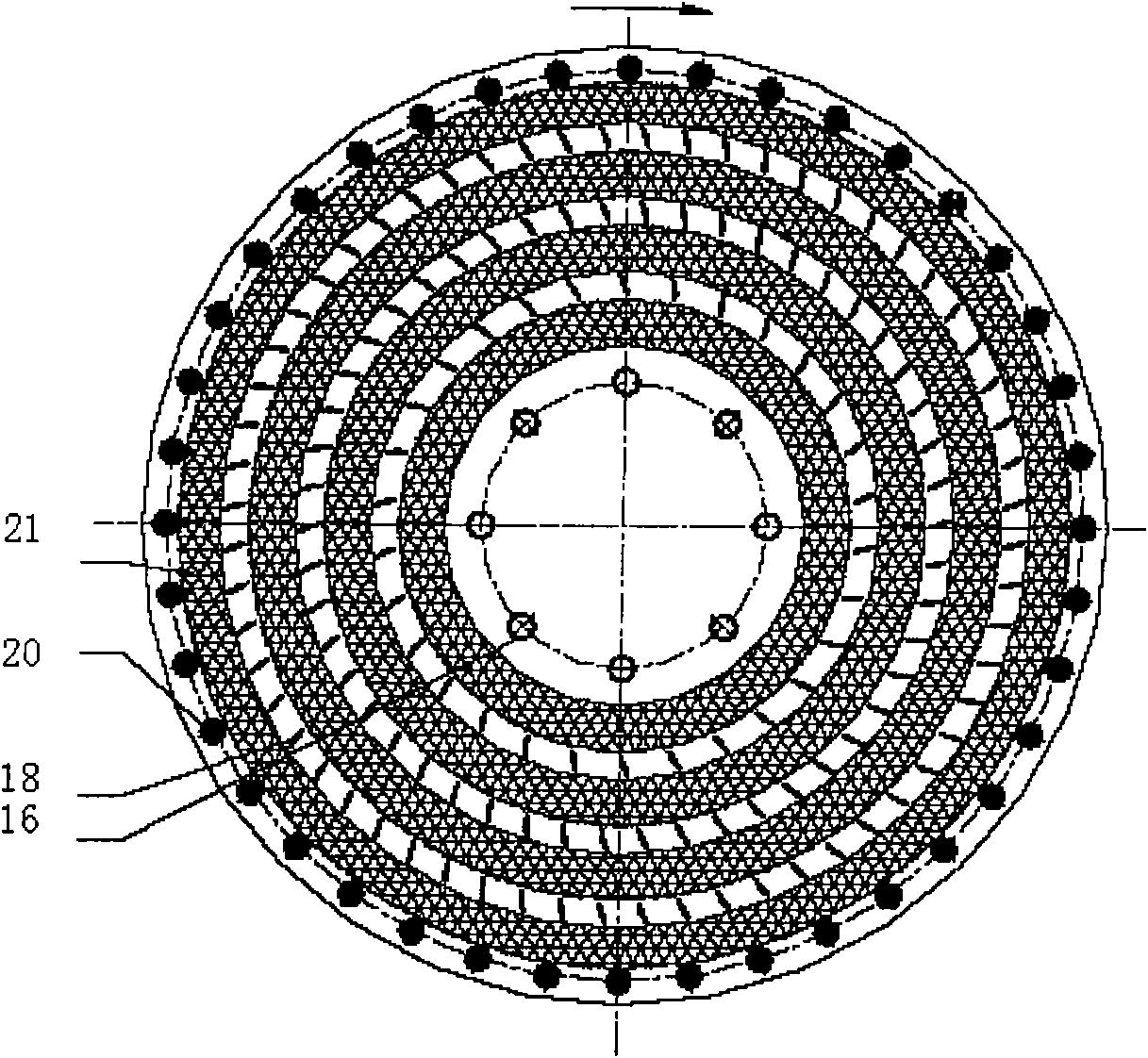

[0032] Embodiment 1: adopt device and technique of the present invention, feed gas is process industry tail gas, carbon dioxide volume content V in the feed gas i was 13.2%. The absorption liquid is the mass concentration w i 32% potassium carbonate solution, mass concentration w e 2.5% diethanolamine was used as the activator. Absorption process system temperature T a is 70°C, the system temperature T of the desorption process d It is 115°C. The rotor structure of the absorption rotary bed and the desorption rotary bed is a straight blade rotor, and the rotor filling layer is 4 layers of packing layers and 3 layers of straight blades arranged at intervals in the radial direction from the inside to the outside. In the absorption process, the exhaust gas from the process industry is passed into the absorption rotating bed with a rotor speed of 500r / min, and after being distributed by the perforated baffle installed in the shell, it enters the rotor packing layer from the o...

Embodiment 2-22

[0033] Examples 2-22: The process flow and steps are the same as those in Example 1. See Table 1 for details of the process conditions, operating conditions and corresponding experimental results of each example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com