Super gravity liquid absorption dehumidifying and regenerating system

A regenerative system and super-gravity technology, which is applied in air-conditioning systems, heating methods, lighting and heating equipment, etc., can solve the problems of limited improvement range, and achieve the reduction of floor space and space volume, safe and reliable devices, and gas-liquid transmission. The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

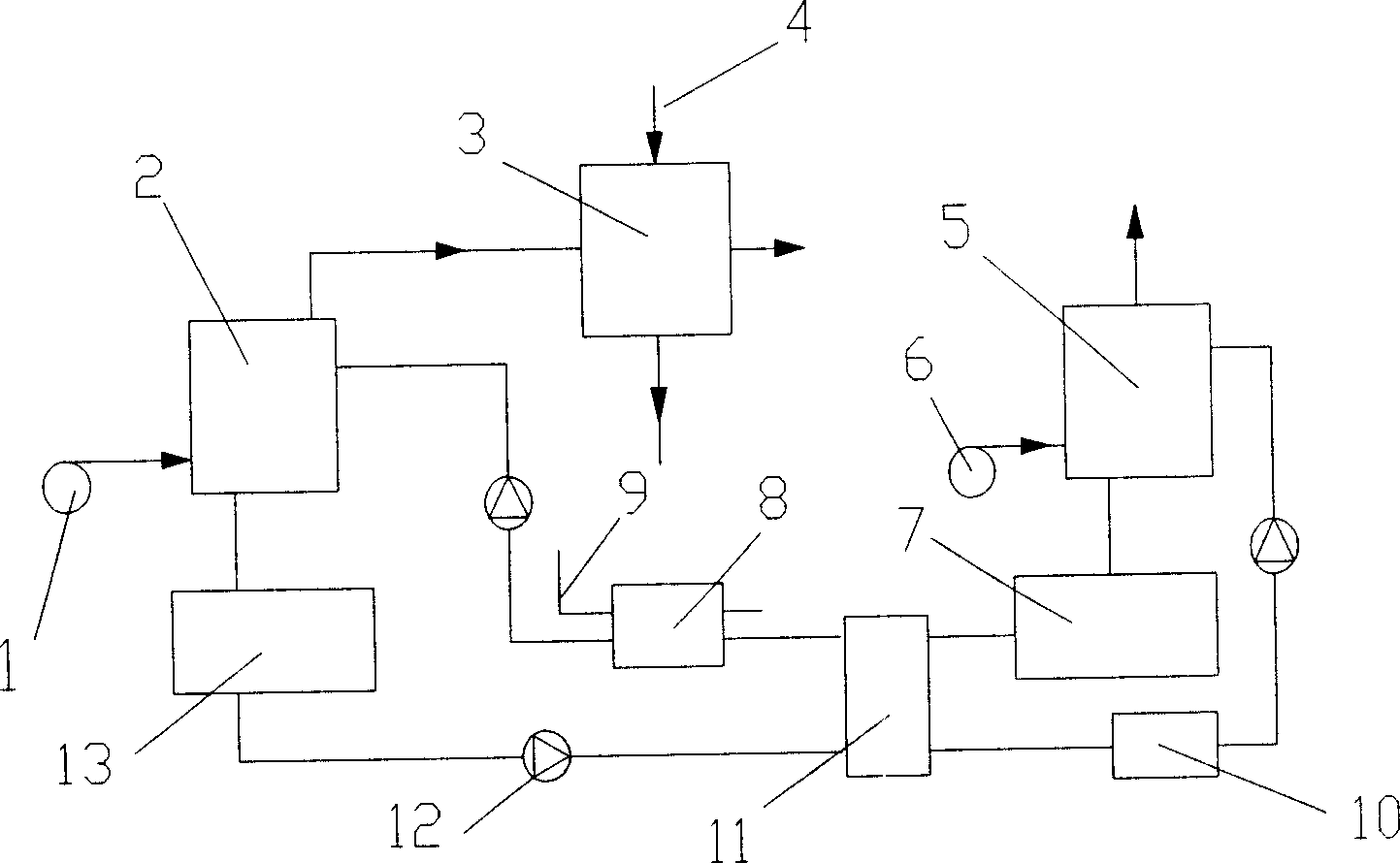

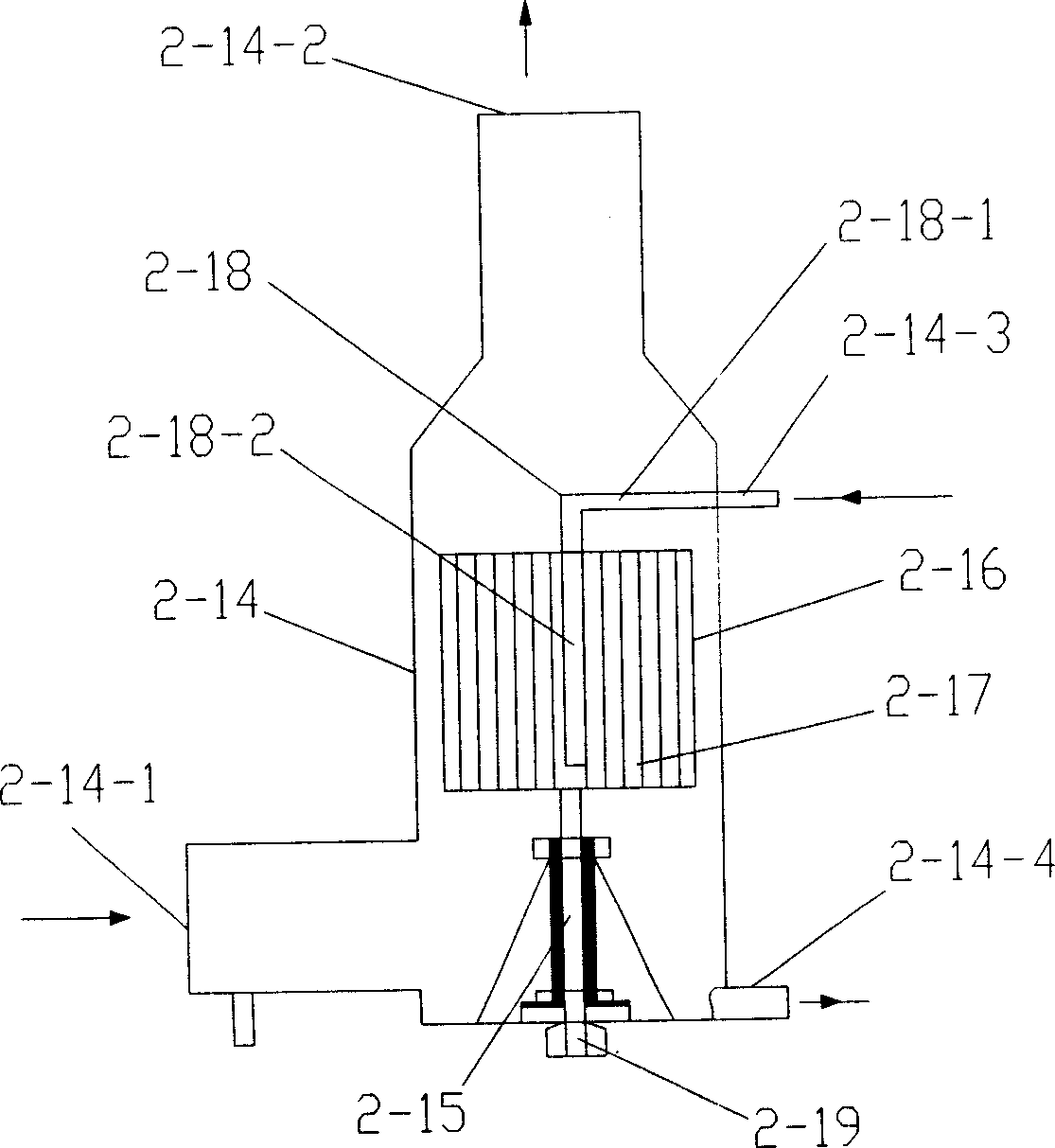

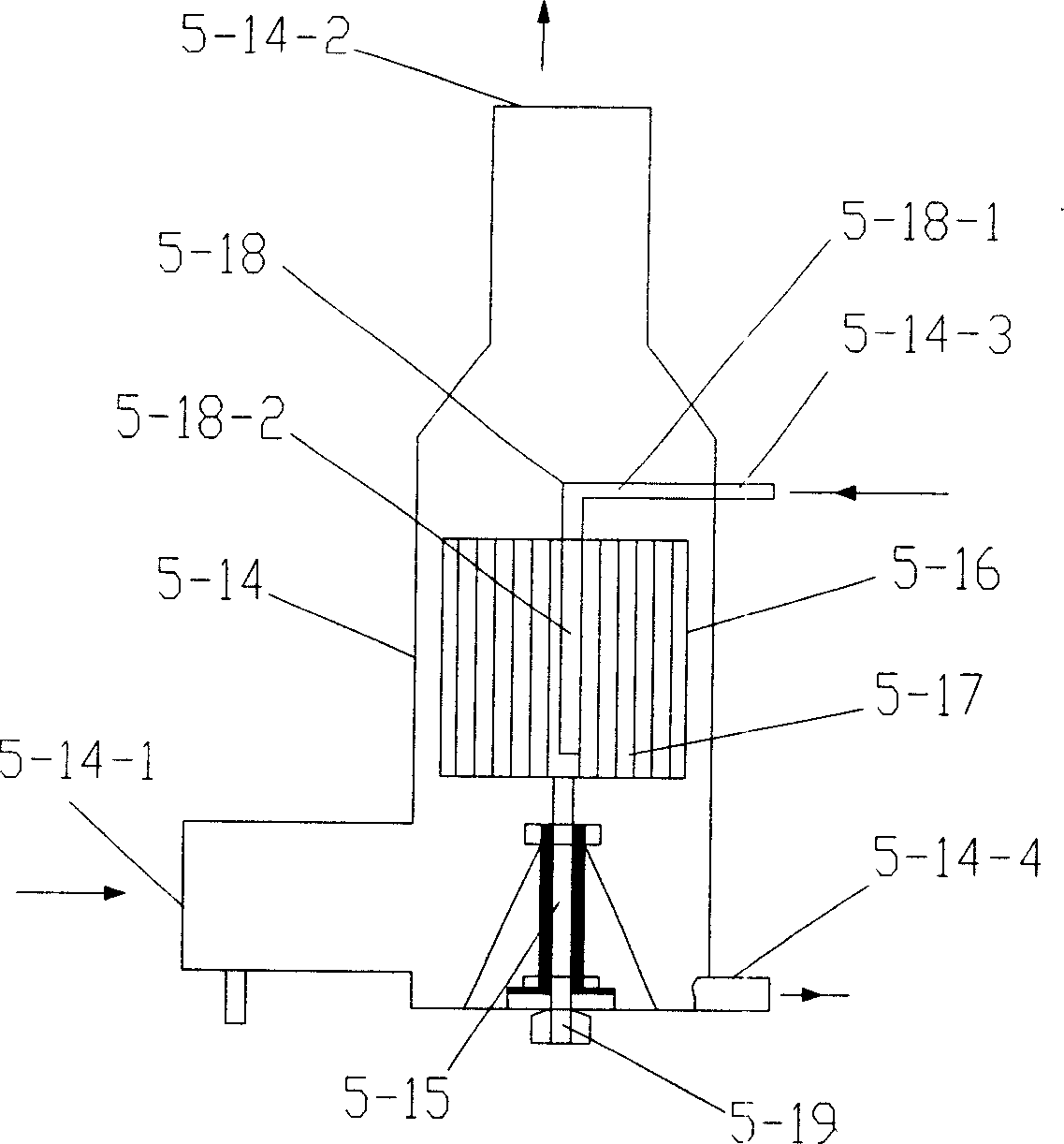

[0034] figure 1 A schematic flow chart of the supergravity liquid absorption dehumidification and regeneration system of the present invention is given, as figure 1 As shown, the supergravity liquid absorption dehumidification and regeneration system includes a supergravity absorber 2 and a supergravity regenerator 5. The supergravity absorber 2 communicates with indoor air, and the supergravity regenerator 5 communicates with outdoor air. The liquid discharge port of the liquid storage tank 13, the tube side of the heat exchanger 11, the regeneration heater 10, the liquid inlet of the supergravity regenerator 5 successively, and the liquid inlet of the supergravity absorber 2 successively connects with the cooler 8, The heat exchanger 11 is connected to the shell side, the hot liquid storage tank 7, and the drain port of the supergravity regenerator 5. The cooler 8 is connected to the cooling water pipe 9. Between the cold liquid storage tank 13 and the heat exchanger 11, the...

Embodiment 2

[0038] Such as figure 1 As shown, the process of the supergravity liquid absorption dehumidification and regeneration system of the present invention is the same as that described in Example 1.

[0039] Figure 4 gives figure 1 Another specific structure of the shown hypergravity absorber 2, such as Figure 4 As shown, the supergravity absorber 2 includes a housing 2-20, a rotating shaft 2-21, a packing bed 2-22, and the housing 2-20 is provided with an air inlet 2-20-1 and an air outlet 2-20-2 , the liquid inlet 2-20-3, the liquid discharge port 2-20-4, the liquid discharge port 2-20-4 is set at the bottom of the shell 2-20, the rotating shaft 2-21 and the air flow through the packing bed 2-22 The direction is vertical, and the air and the liquid LiCl solution are in countercurrent contact in the packed bed 2-22, and the packed bed 2-22 is fixedly connected to the inner end of the rotating shaft 2-21, and a packing metal foam 2-23 and a static liquid distributor are arrang...

Embodiment 3

[0042] Such as figure 1 As shown, the process flow of the supergravity liquid absorption dehumidification and regeneration system of the present invention is the same as that of Embodiment 1.

[0043] Such as figure 2 As shown, the structure of the hypergravity absorber 2 is the same as that described in the hypergravity absorber 2 in Example 1, wherein the fillers 2-17 are ceramics, and the liquid is CaCl2 solution.

[0044] Such as Figure 5 As shown, the structure of the high-gravity regenerator 5 is the same as the structure of the high-gravity regenerator 6 in Embodiment 2, wherein the filler 5-23 is ceramics, and the liquid is CaCl2 solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com