Hydraulic driving type push plate wave making test device under supergravity condition

A test device and super-gravity technology, applied in the field of hydraulically driven push plate wave-making test device, can solve the problems of small motor output torque, poor wave dissipation effect, inability to adjust the position and opening ratio of the wave dissipation plate, and achieve Enhanced reliability, simple form, and improved wave suppression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

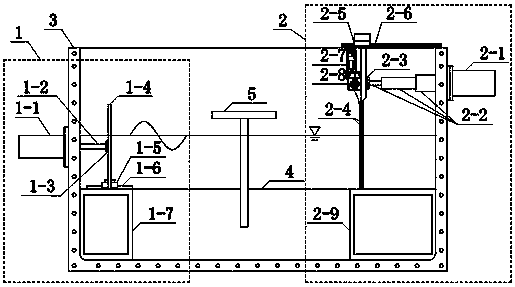

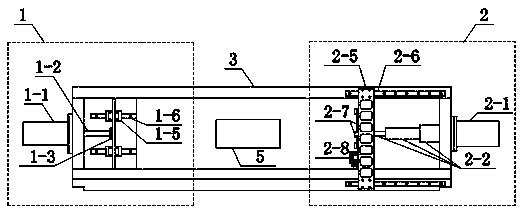

[0028] Such as figure 1 , figure 2 As shown, the device of the present invention includes a wave making unit 1, a wave dissipation unit 2, a model box 3, a seabed model 4, a marine structure model 5 and two sets of hydraulic drive systems; on the left side of the model box 3 filled with liquid The wave-making unit 1 is installed on the inner wall, and the wave-making hydraulic cylinder 1-1 of the wave-making unit 1 is installed on the left outer wall of the model box 3; The hydraulic cylinder 2-1 is installed on the outer wall of the right side of the model box 3; the groove formed between the bottom stopper 1-7 of the wave-making unit and the bottom stopper 2-9 of the wave-dissipating unit contains a seabed model 4 and a seabed model 4 The offshore structure model 5 is buried in the center; two sets of hydraulic drive systems installed outside the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com