Column and machine combined gas desulphurization process device and desulphurization method thereof

A desulfurization process, combined with gas technology, applied in the direction of liquid scrubbing gas purification, etc., can solve the problems of increased sulfur sulfide content in gas, no waste liquid treatment process, etc., achieve pollution-free secondary pollution, improve operating environment and product storage and transportation The difficulty of the desulfurization equipment and the efficient effect of the desulfurization equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

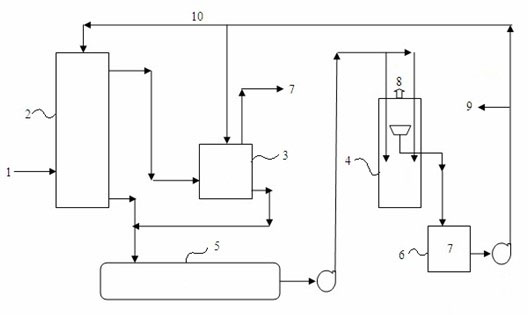

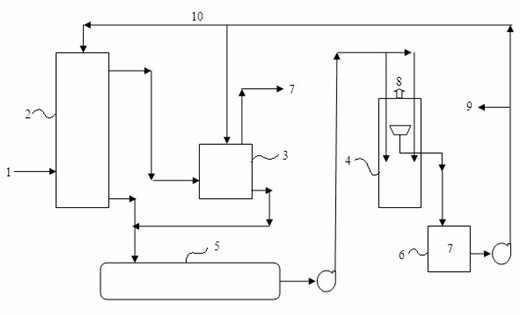

[0018] like figure 1 As shown, the first type of tower-crane combined gas desulfurization process device is a two-stage desulfurization system sharing a set of regeneration system. Sulfur-containing gas (gas) 1 first enters from the bottom of the packed absorption tower (desulfurization tower) 2, contacts upward with the desulfurization liquid 10 entering from the top, absorbs by convection reaction, and the preliminarily purified gas is discharged from the top of the packed absorption tower 2 and enters The cyclone type supergravity desulfurizer 3 reacts strongly with the desulfurization liquid again in the cyclone type supergravity desulfurizer 3, and the purified gas 7 is ejected through the cyclone type supergravity desulfurizer 3 and enters the next section.

[0019] The desulfurization liquid in the packed absorption tower 2 and the cyclone supergravity desulfurizer 3 flows into the reaction tank 5, and is then pressurized by the rich liquid pump to the half-tower regene...

Embodiment 2

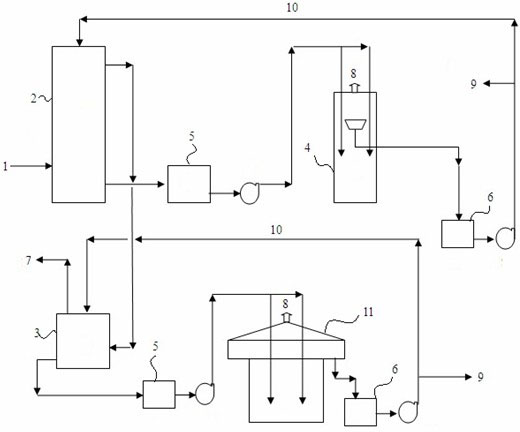

[0021] like figure 2 , The first type of tower crane combined with gas desulfurization process device sets up regeneration systems independently for each of the two-stage desulfurization systems. Sulfur-containing gas (gas) 1 first enters the packed absorption tower (desulfurization tower) 2, and is in convective contact with the desulfurization liquid 10 sprayed from the top of the tower, thereby removing hydrogen sulfide in the gas, and the preliminarily purified gas is absorbed from the packing The tower 2 tops out and enters the cyclone supergravity desulfurizer 3, where it reacts strongly with the desulfurization liquid again in the cyclone supergravity desulfurizer 3, and the purified gas 7 is topped out through the cyclone supergravity desulfurizer 3 , enter the next section.

[0022] The desulfurized rich liquid in the packed absorption tower 2 flows to the reaction tank 5 by itself, and then is sent to the half-tower regeneration tower 4 by the rich liquid pump unde...

Embodiment 3

[0024] No matter whether the process device of Example 1 or Example 2 is used, in order to not produce sulfur bubbles or sulphur in the desulfurization process, any lye solution of ammonia or sodium-alkali is used as the desulfurization liquid, and polyquinone is used as the desulfurization liquid. Sulfonates and phenolic compounds act as catalysts (ZZNQ). The desulfurization liquid is suitable for the packed absorption tower 2 and the cyclone supergravity desulfurizer 3. Its desulfurization mechanism is:

[0025] With lye (M + ) absorbs acid gases such as hydrogen sulfide and hydrogen cyanide from the process gas, and the catalyst simultaneously oxidizes part of the generated hydrogen sulfide (M.HS) into polysulfide (M.HS) 2 S nx+1 ), the polysulfide reacts rapidly with hydrogen cyanide in solution to form thiocyanate (MCNS). Regeneration of catalyst (NQ=O) by reaction with air oxygen.

[0026] The reaction formula of the absorption process is:

[0027] H 2 S+M + →M.H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com