Method for purifying aluminum and aluminum alloy melt through supergravity filtering and recombination

An aluminum alloy melt and composite purification technology, which is applied in the direction of improving process efficiency, can solve the problems of poor removal effect of small-sized inclusions, and achieves the effect of low cost and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

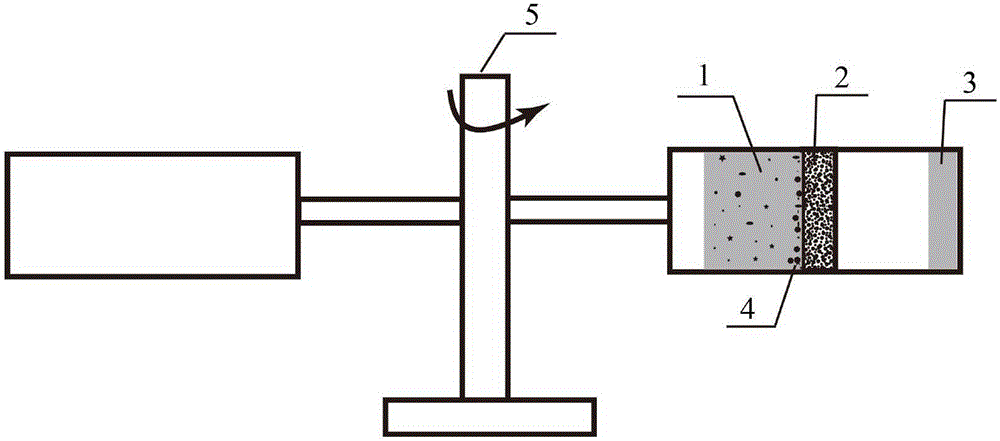

Method used

Image

Examples

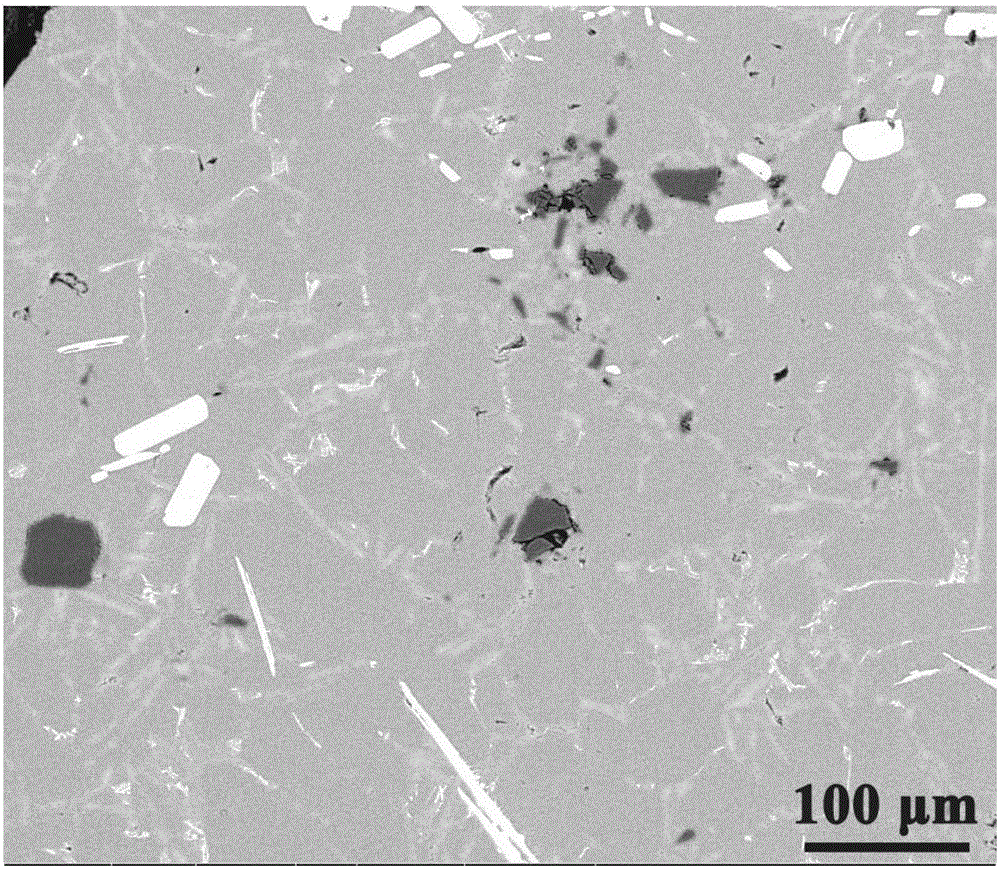

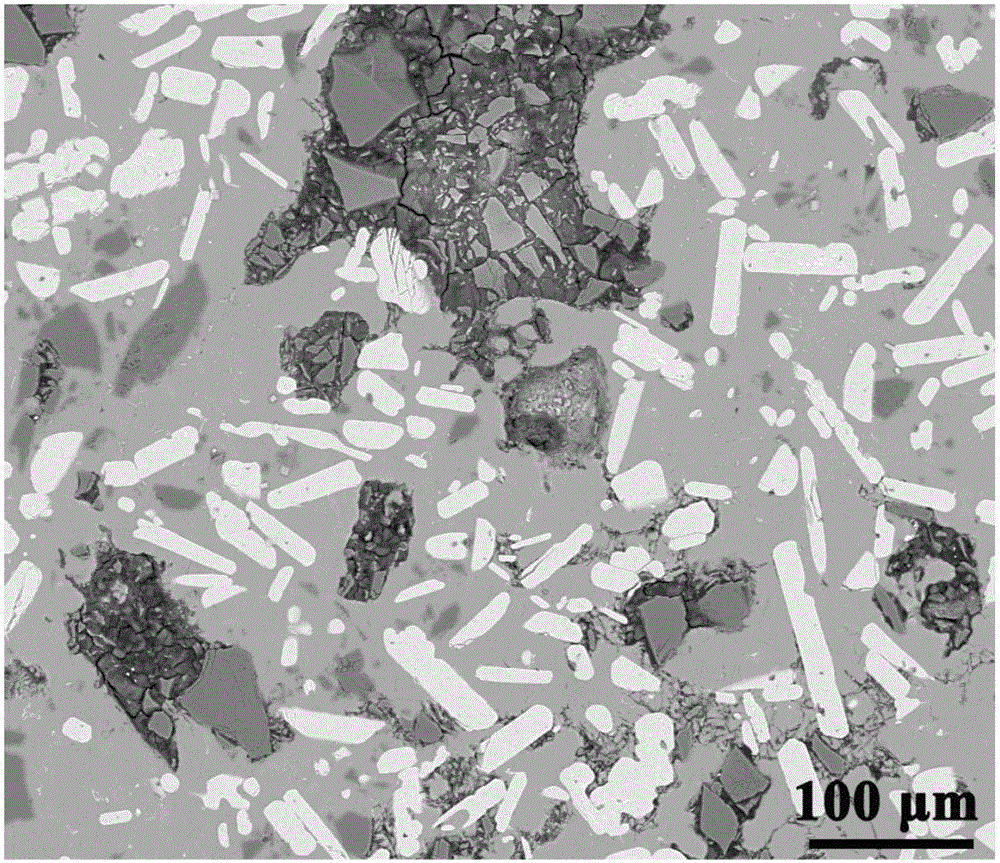

Embodiment 1

[0026] Put an appropriate amount of original aluminum alloy and protective slag into the filter crucible and put them into a supergravity heating furnace to raise the temperature to 700°C. After holding the heat for 10 minutes, turn on the centrifuge and adjust the speed to 600r / min and 1338r / min respectively. The corresponding gravity The coefficients are G=100 and G=500, respectively. Under the condition of constant temperature of 700°C, perform supergravity filtration treatment for 2 minutes, then close the centrifuge, take out the sample and spray water to cool it quickly. The obtained upper filter slag and the lower filter purified aluminum were inlaid, roughly ground and polished, and their microstructure was observed with a scanning electron microscope. The results are as follows: Figure 3-1 , 3-2 shown. Here the Ti element content in the aluminum alloy is much more than 0.5%, and the coarse Al 3 Ti has an adverse effect on the performance of the alloy, so Ti in the...

Embodiment 2

[0030] Put an appropriate amount of raw aluminum alloy and protective slag into the filter crucible and put them into a supergravity heating furnace to raise the temperature to 700°C. After holding the heat for 10 minutes, turn on the centrifuge and adjust the speed to 423r / min, respectively, and the corresponding gravity coefficient is G =50. Under the condition of constant temperature of 700°C, high-gravity filtration was carried out for 2 minutes and 10 minutes respectively, and then the centrifuge was turned off, and the sample was taken out and sprayed with water for rapid cooling. ICP-OES and oxygen, nitrogen and hydrogen analyzer were used to measure the impurity element Ti and oxygen content of the obtained purified aluminum, and calculate the removal rate of oxide inclusions and impurity element phases. The results are shown in Table 2.

[0031] Table 2. Removal rate of inclusions in purified aluminum obtained at different treatment times under gravity coefficient G=5...

Embodiment 3

[0034] Put an appropriate amount of original aluminum alloy and mold slag into the filter crucible and put them into the supergravity heating furnace to heat up to a specific temperature. After holding the heat for 10 minutes, turn on the centrifuge and adjust the speed to 423r / min, respectively, and the corresponding gravity coefficient is G =50. Under the constant temperature conditions of 700°C and 750°C, perform supergravity filtration treatment for 2 minutes, then close the centrifuge, take out the sample and spray water to cool it quickly. ICP-OES and oxygen, nitrogen and hydrogen analyzer were used to measure the impurity element Ti and oxygen content of the obtained purified aluminum, and calculate the removal rate of oxide inclusions and impurity element phases. The results are shown in Table 3.

[0035] Table 3. The removal rate of inclusions in purified aluminum obtained at different treatment temperatures under gravity coefficient G = 50

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com