Novel passive super-gravity rotary bed device

A supergravity rotating bed, a new type of technology, applied in mixers with rotating stirring devices, transportation and packaging, separation methods, etc., can solve problems such as power consumption, and achieve the effects of reducing energy consumption, compact structure, and improved safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

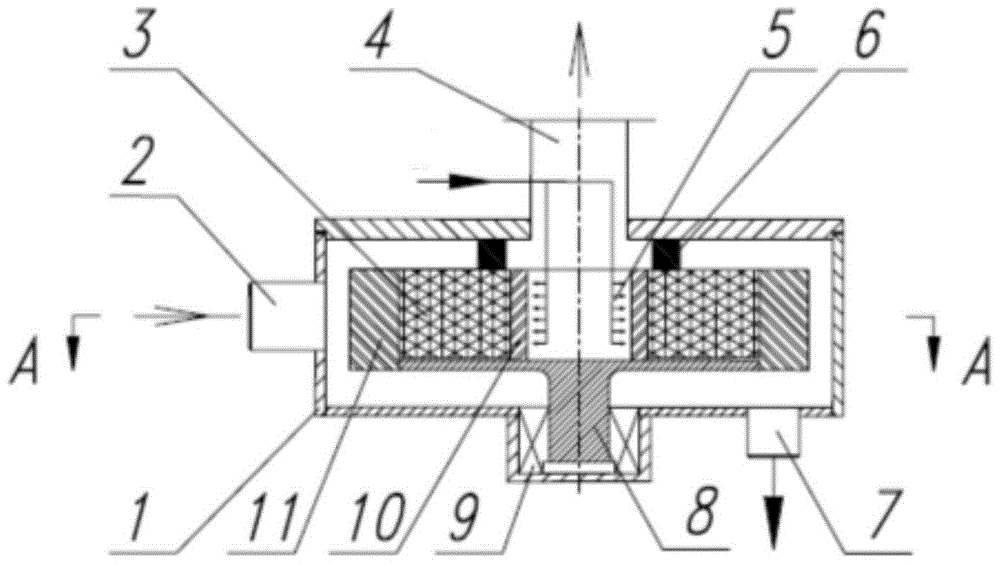

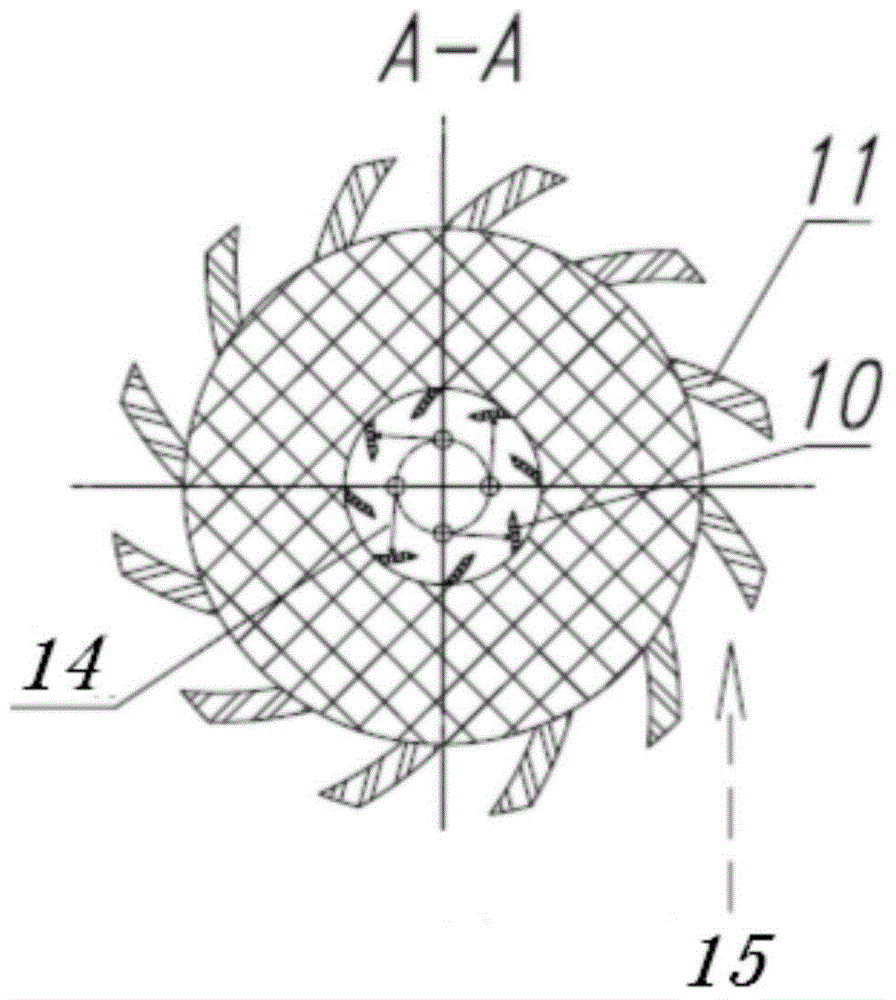

[0031] see figure 1 , 2 As shown, a passive high-gravity rotating bed device includes a housing 1, a rotor 3, a rotating shaft 8, a gas pipeline one 2, a gas pipeline two 4, a liquid distributor 5 and a liquid outlet 7; the liquid The outlet 7 is arranged at the lower part of the casing 1; the rotor 3 is arranged in the casing 1, and a sealing device 6 is provided between the rotor 3 and the casing 1, so that the gas and liquid entering all need to pass through the rotor; the casing 1 The bottom is provided with a groove, and a bearing 9 is arranged in the groove, and the rotating shaft 8 is fixed in the bearing 9, that is, the rotating shaft 8 is vertically arranged; in this way, the entire rotating shaft 8 is fixed in the housing 1, and the rotating shaft 8 and the housing 1 do not need to be sealed, which can reduce equipment cost; the inner edge of the rotor 3 is provided with rotor inner edge blades 10, and the outer edge of the rotor 3 is provided with rotor outer edge ...

Embodiment 2

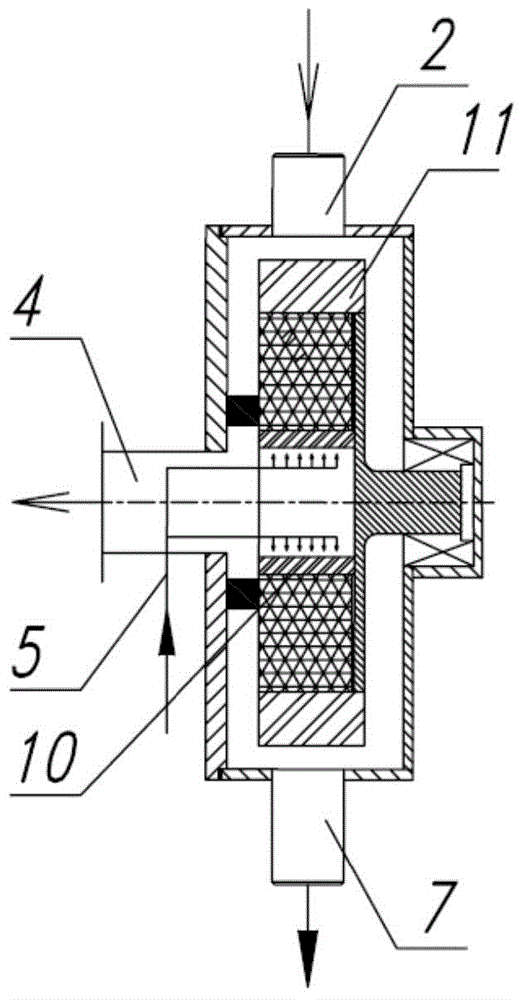

[0035] see image 3 As shown, the embodiment 1 is repeated, the only difference is that the rotating shaft 8 is horizontally arranged in the housing 1 .

Embodiment 3

[0037] A kind of application of the device described in the above-mentioned embodiment 1 in the separation process of multiphase flow:

[0038] see Figure 4 Shown, with high pressure natural gas CO 2 Absorption as an example; using CO 2 The high-pressure natural gas with a content of 10% enters from the gas pipeline 1 to drive the outer edge blades 11 of the rotor to drive the rotor to rotate; MDEA with an absorption liquid of 40wt% enters the liquid distributor 5 from the liquid inlet, and the gas-liquid countercurrent contact completes the mass transfer process , the liquid flows out from the liquid outlet 7, and the gas flows out from the gas pipeline 2 4 . CO 2 The content is 2.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com