Preparation method of high-modulus potassium silicate inorganic nano-resin

A technology of inorganic nanometer and potassium silicate, which is applied in alkali metal silicate coatings, anti-corrosion coatings, coatings, etc., can solve the problems of poor storage stability, long reaction time, and poor quality, so as to improve quality and reduce by-products , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

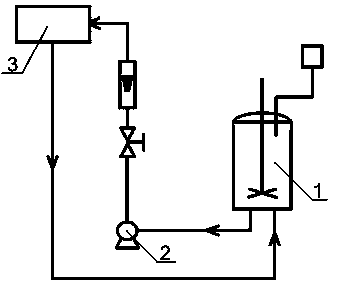

[0029] The preparation process of the high-modulus potassium silicate inorganic nano-resin is to firstly add the prefabricated mixture into the high-gravity rotating packed bed 3, and then circulate the reaction to prepare the high-modulus potassium silicate inorganic nano-resin.

[0030] The preparation process of the high-modulus potassium silicate inorganic nano-resin is as follows: firstly, the prefabricated mixture is heated to 40-80°C, and then at this temperature, the heated prefabricated mixture flows out from the mixer 1, and is sequentially passed through Circulating pump 2, high-gravity rotating packed bed 3, then return to mixer 1 to complete a cyclic reaction cycle, and then enter the next cyclic reaction cycle, which is repeated in sequence until the cyclic reaction ends, and finally high modulus silicon is obtained in mixer 1 Potassium acid inorganic nano resin.

[0031] The rotation speed of the high-gravity rotating packed bed 3 is 1500-3000 rpm, and the cycle...

Embodiment 1

[0050] see figure 1 , a preparation method of high modulus potassium silicate inorganic nano-resin, the preparation method comprises the following processes in sequence:

[0051] Mixing process of raw materials: at room temperature, first add a low modulus potassium silicate aqueous solution with a modulus of 3.3 and a solid content of 32.6% to the mixer 1, and control the stirring speed at 400-600rpm to form a vortex, and then add in turn Ionized water, silica sol with a solid content of 38%, ethoxylated water-based silicone resin, and finally methyltrimethoxysilane is added dropwise, and the prefabricated mixture is obtained after mixing evenly, among which, low modulus potassium silicate aqueous solution, deionized water , the mass ratio of silica sol, ethoxylated water-based silicone resin, and methyltrimethoxysilane is 100:25:35:1:5, and the time for adding the coupling agent is 10 to 30 minutes;

[0052] The preparation process of high-modulus potassium silicate inorgan...

Embodiment 2

[0055] The steps are the same as in Example 1, except that the mass ratio of low modulus potassium silicate solution, deionized water, silica sol, ethoxylated water-based silicone resin, and methyltrimethoxysilane is 100:30:43.1:3 : 3.49, the cycle reaction time is 7min.

[0056] The prepared high-modulus potassium silicate inorganic nano-resin has a modulus of 5.6, a yield of 98.5%, a solid content of 26.6%, a particle size of 5-10 nm, a density of 1.19, and a storage time of 2 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com