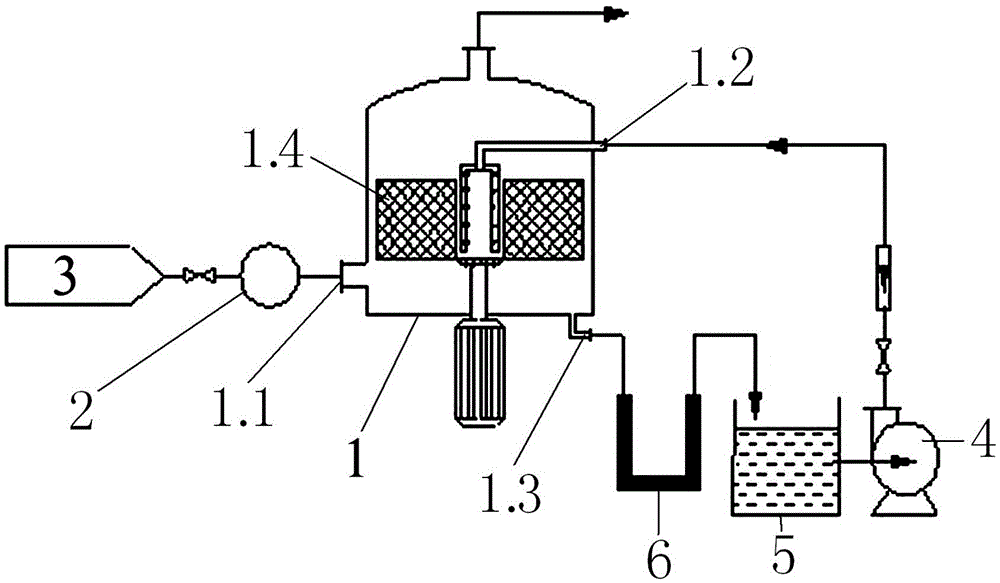

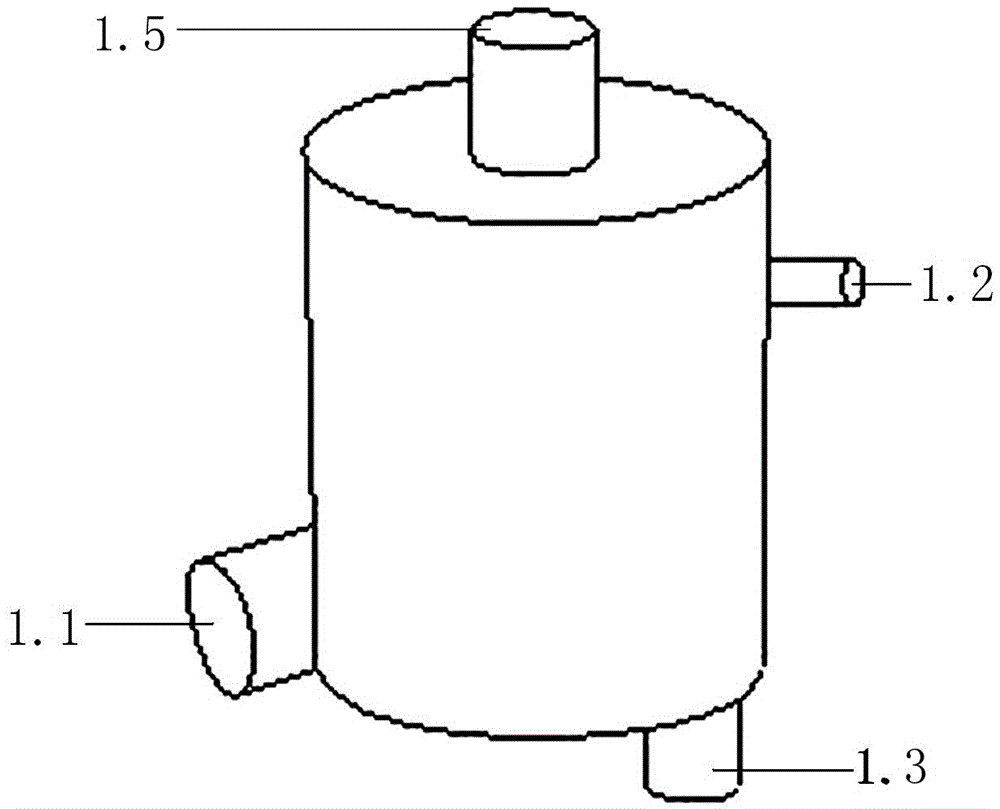

Device and method for removing fine particles in gas in supergravity manner

A technology for removing gas and fine particles, which is applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of low removal rate of fine particles, inability to operate continuously, and short residence time, etc., to extend the residence time, Effects of avoiding boundary layer separation and improving classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

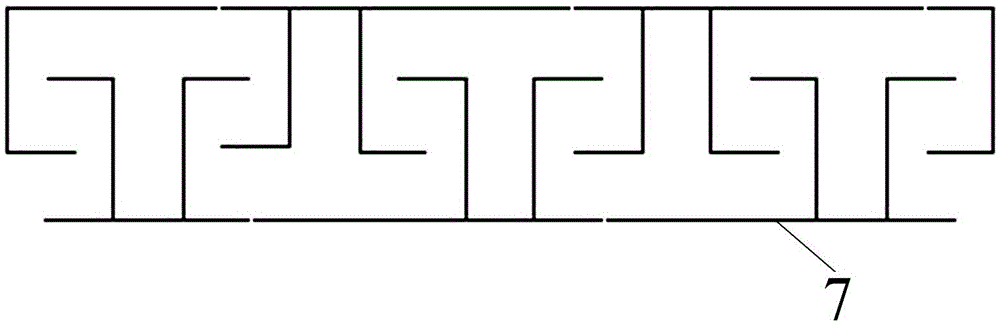

Embodiment 1

[0024] Example 1: The dust concentration of blast furnace tail gas in a steelworks is about 10g / m 3 , using this as the dusty gas to carry out the pilot test, the treatment gas volume is 500m 3 / h, gas velocity is 10m / s, suitable liquid volume is 0.3m 3 / h, the outer diameter of the plastic Pall ring packing in the supergravity rotating packed bed is 16mm, the rotating speed of the supergravity rotating packed bed is 600r / min, and the liquid-gas ratio in the supergravity rotating packed bed is 0.2L / m 3 , the gas phase pressure drop of the high-gravity rotating packed bed is 150Pa, sodium lauryl sulfate is added to the water to prepare a foaming agent solution with a mass concentration of 0.05%, and the measured total dust removal efficiency is 98.7%. Among them, PM 2.5 The removal rate is 96%, PM 1.0 The removal rate is 89%.

Embodiment 2

[0025] Example 2: In a production line producing nitrophosphate fertilizer, 200,000 m3 will be discharged 3 / h of gas containing compound fertilizer dust, the dust particles are fine, the concentration is about 4g / m 3 . Use this as the dusty gas to carry out the pilot test, the treatment gas volume is 800m 3 / h, gas velocity is 15m / s, suitable liquid volume is 0.3m 3 / h, the outer diameter of the plastic Pall ring packing in the supergravity rotating packed bed is 35mm, the rotating speed of the supergravity rotating packed bed is 500r / min, and the liquid-gas ratio in the supergravity rotating packed bed is 0.3L / m 3 , the gas phase pressure drop of the high-gravity rotating packed bed is 180Pa, adding span series of surfactants in water to prepare a foaming agent solution with a mass concentration of 0.01%, the measured total dust removal efficiency is 99.5%, of which, PM 2.5 The removal rate is 97%, PM 1.0 The removal rate is 88.5%.

Embodiment 3

[0026] Embodiment 3: using 2000 mesh talcum powder simulation concentration is 15g / m 3 of dusty gas, the treatment gas volume is 600m 3 / h, the gas velocity into the supergravity rotating packed bed is 20m / s, and the suitable liquid volume is 0.15m 3 / h, the outer diameter of the plastic Pall ring packing in the supergravity rotating packed bed is 50mm, the speed of the supergravity rotating packed bed is 400r / min, and the liquid-gas ratio in the supergravity rotating packed bed is 0.4L / m 3 , the gas-phase pressure drop of the high-gravity rotating packed bed is 200Pa, adding tween series wetting agents in water to prepare a foaming agent solution with a mass concentration of 0.1%, and the measured total dust removal efficiency is 99.7%. Among them, PM 2.5 The removal rate is 98%, PM 1.0 The removal rate is 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com