Glyoxal cross-linked polymer modified nano crystalline cellulose as well as preparation method and application thereof

A technology of cross-linked polymer and nano-crystal, applied in the direction of reinforcing agent addition, etc., can solve the problems of ineffective adsorption of polymers, decrease of dehydration rate of wet paper web, increase of dry strength of paper, etc., so as to improve system retention rate, physical The effect of strength improvement and retention rate improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

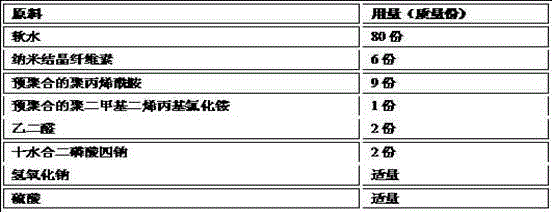

[0034] A preparation method of glyoxal cross-linked polymer modified nanocrystalline cellulose provided in this example, the main raw materials used and the amount of feed are shown in the following table:

[0035]

[0036] The preparation method comprises the following steps:

[0037] Add 1200g of soft water to a 2000ml flask with a turbine stirrer and RTD temperature sensor, add 90g of nanocrystalline cellulose at a stirring speed of 120RPM, heat up to 50°C while stirring, and cool to room temperature after completely dissolving.

[0038] Polyacrylamide polymer (molecular weight 10,000 daltons) 135g, polydimethyldiallylammonium chloride polymer (molecular weight 10,000 daltons) 15g, tetrasodium diphosphate decahydrate 30g, glyoxal 30g , after stirring evenly, adjust the pH value to 8.5 with appropriate amount of sodium hydroxide and dilute sulfuric acid.

[0039] After reaching the desired viscosity, adjust the pH with an appropriate amount of concentrated sulfuric acid ...

specific Embodiment 2

[0043] A preparation method of glyoxal cross-linked polymer modified nanocrystalline cellulose provided in this example, the main raw materials used and the amount of feed are shown in the following table:

[0044]

[0045] The preparation method comprises the following steps:

[0046] Add 1230 g of soft water to a 2000 ml flask with a turbine stirrer and RTD temperature sensor, add 75 g of nanocrystalline cellulose at a stirring speed of 120 RPM, heat up to 50 ° C while stirring, and cool to room temperature after completely dissolving.

[0047] Poly N,N-dimethylacrylamide polymer (molecular weight 12,000 Daltons) 120g, polydimethyldiallylammonium chloride polymer (molecular weight 10,000 Daltons) 15g, decahydrate diphosphate tetra Sodium 30g, glyoxal 30g, after stirring evenly, adjust the pH value to 8.5 with appropriate amount of sodium hydroxide and dilute sulfuric acid.

[0048] After reaching the desired viscosity, adjust the pH with an appropriate amount of concentr...

specific Embodiment 3

[0052] The monomer of poly N,N-dimethylacrylamide in specific example 2 is replaced by acrylamide, N,N-dimethylacrylamide, N,N-diethylacrylamide, N-vinyl One or more nonionic monomers in formamide, acrylonitrile; the monomer of polydimethyldiallyl ammonium chloride in specific embodiment 2 is replaced by being selected from dimethyldiallyl chloride Ammonium, quaternary ammonium methyl chloride of dimethylaminoethyl acrylate, quaternary methyl chloride of dimethylaminoethyl methacrylate, quaternary methyl chloride of diethylaminoethyl acrylate, methyl methyl chloride quaternary ammonium salt of diethylaminoethyl acrylate, methyl chloride quaternary ammonium salt of dimethylaminopropyl acrylamide, methyl chloride quaternary ammonium salt of dimethylaminopropyl methacrylamide, acrylic acid di Benzyl chloride quaternium salt of methylaminoethyl ester, benzyl chloride quaternium salt of dimethylaminoethyl methacrylate, benzyl chloride quaternium salt of diethylaminoethyl acrylate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com