Full-automatic double-head chamfering machine

A double-head chamfering machine, fully automatic technology, applied in metal processing machinery parts, measuring/indicating equipment, milling machine equipment, etc., can solve problems such as chipping, high labor intensity, and unadjustable clamping position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

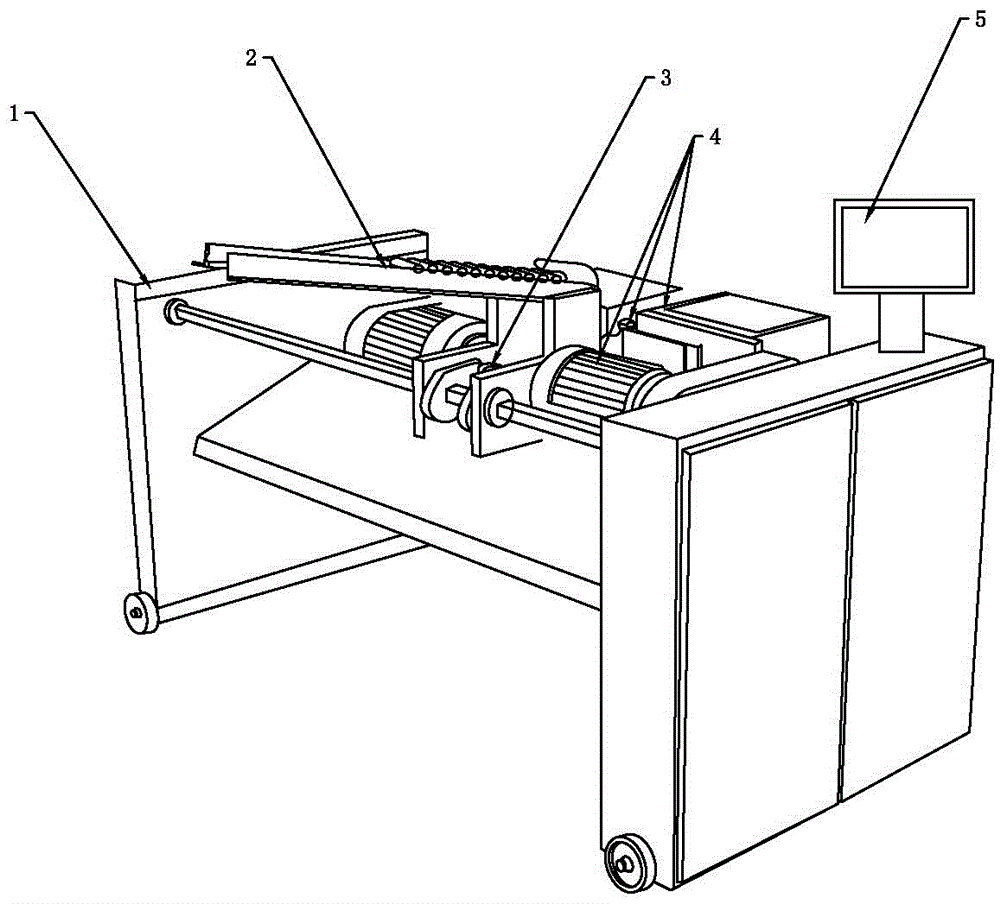

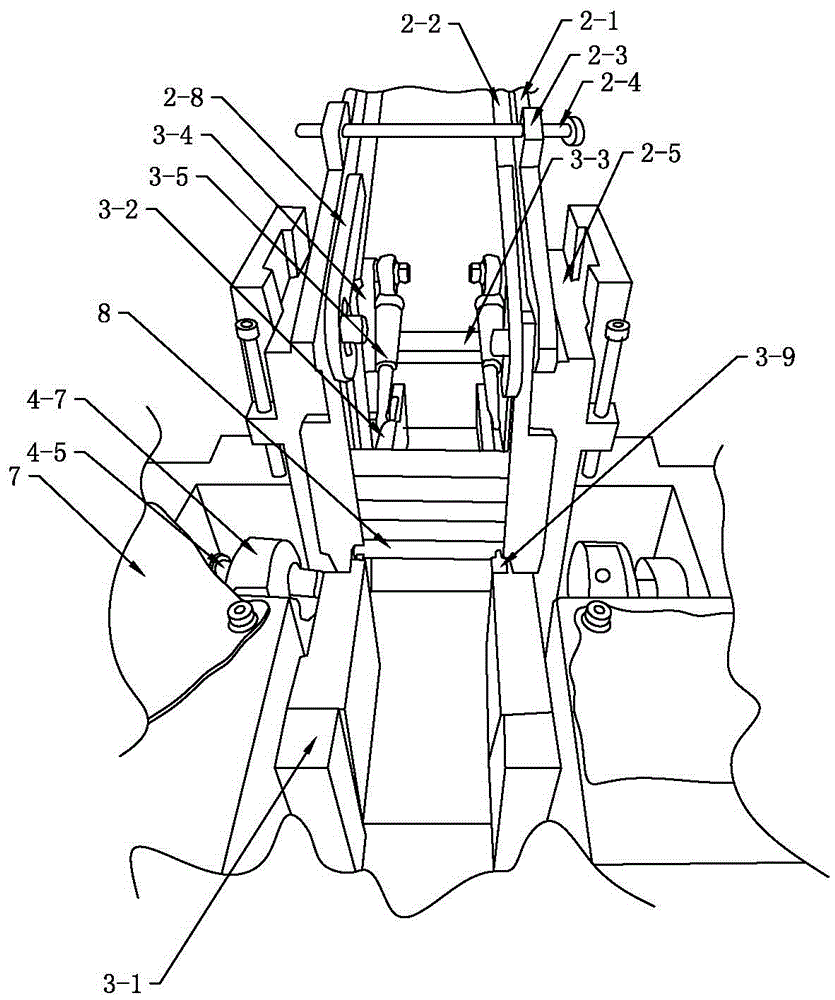

[0047] see Figures 1 to 9 , The fully automatic double-head chamfering machine of this embodiment includes an organism support 1, a feeding mechanism 2, a clamping mechanism 3, a rotary cutting mechanism 4, a photosensitive system, an infrared pulse counter, a blanking receiving device and a microcomputer 6.

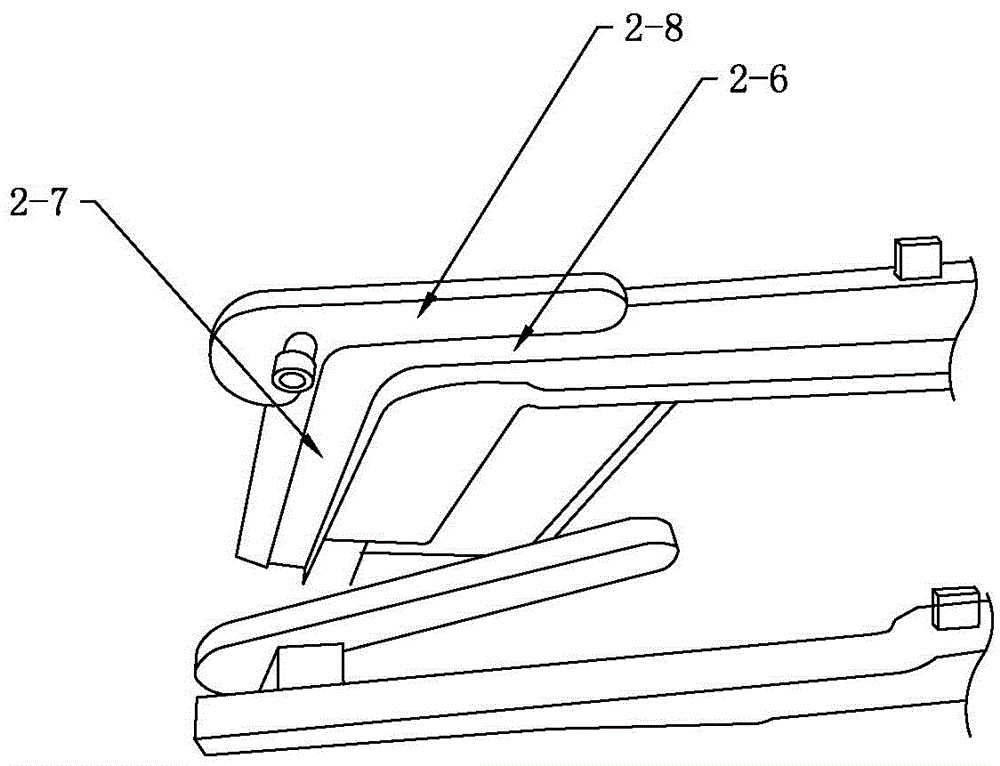

[0048]Wherein, the feeding mechanism 2 includes a feeding roller table and a material guide device, the feeding roller table is composed of two feeding strips 2-1, and the inner sides of the two feeding strips 2-1 are provided with The boss 2-2 of the workpiece 8, the feed track 2-6 is formed above the boss 2-2 of the two feed slats 2-1, and the two feed slats 2-1 are inclined so that the workpiece 8 can use its own Gravity automatically rolls into the feed, because the length of the two feed slats 2-1 is longer and their free ends are easily deformed, causing the feed track 2-6 to be too wide to carry the workpiece 8, the feed slat 2-1 of the present embodiment 1. A w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com