Chamfering machining control method for axle workpieces

A shaft workpiece and control method technology, applied in the field of chamfering processing, can solve problems such as complex operation, low production efficiency, and non-adjustable clamping position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

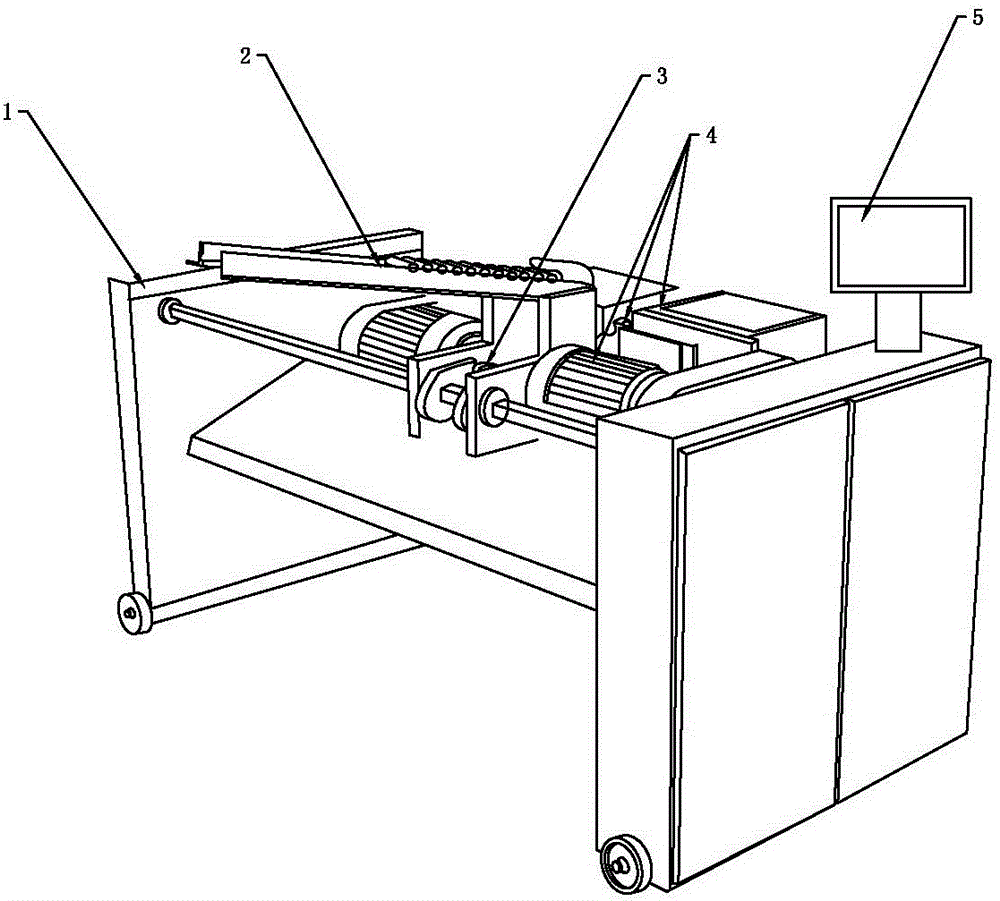

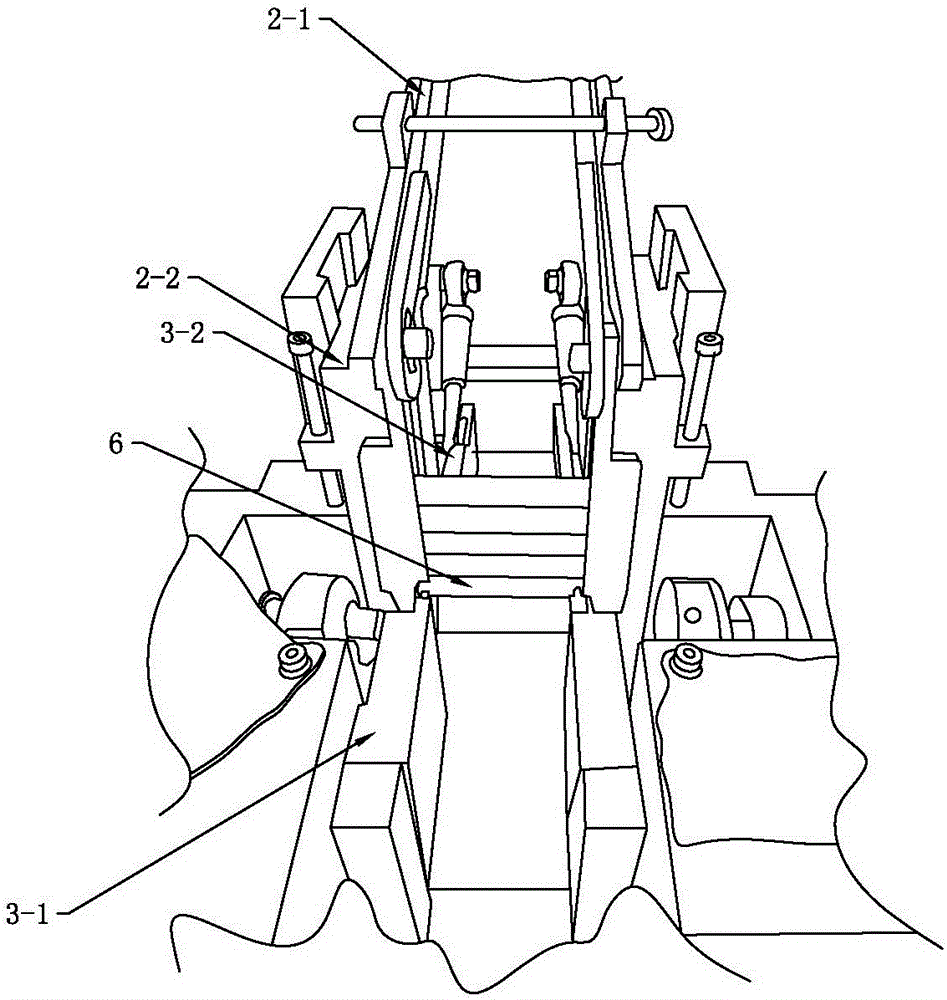

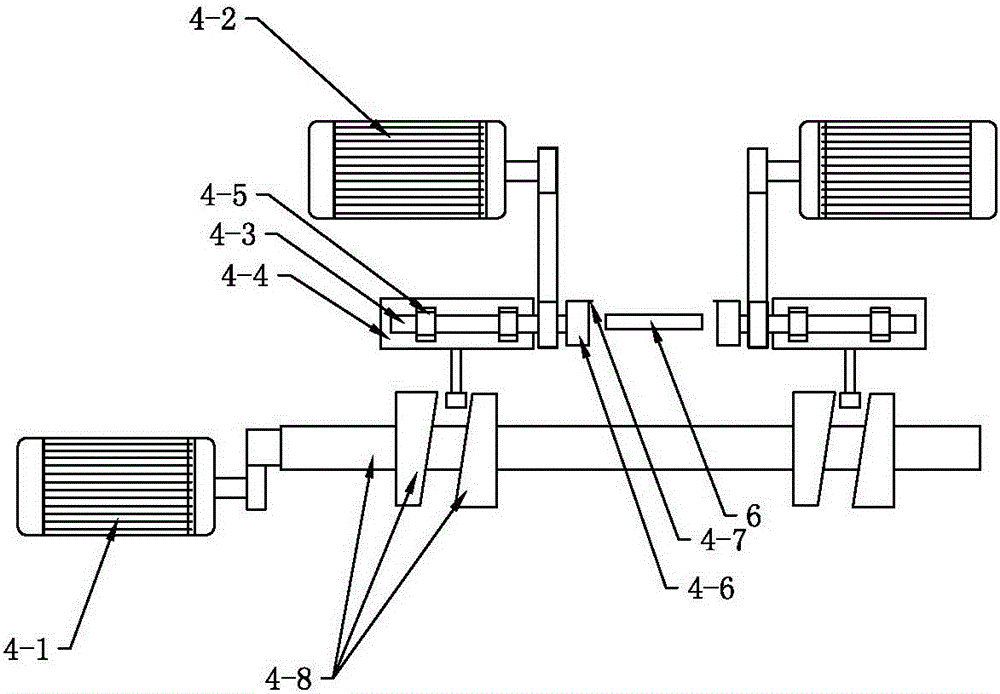

[0039] The chamfering processing control method of the shaft workpiece 6 in this embodiment is applied to a fully automatic double-head chamfering machine, see Figures 1 to 3 , the fully automatic double-head chamfering machine includes an organic support 1, a feeding mechanism 2, a clamping mechanism 3, a rotary cutting mechanism 4, a light sensing system, an infrared pulse counter, a blanking receiving device and a microcomputer 5, and the feeding mechanism 2 includes There are feed roller table and material guide device, the feed roller table is composed of two feed slats 2-1, the material guide device is composed of two material guide plates 2-2 respectively provided with feed grooves, the two guide plates The feed plate 2-2 is fixed on the body support 1, the feed track communicates with the feed trough and the side wall at the bottom of the feed trough is provided with a feed trough outlet.

[0040] The clamping mechanism 3 includes a clamping fixed block 3-1, a clampin...

Embodiment 2

[0054] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In step (4), the forward and backward driving motor drives the cutterhead to advance 12mm at a speed of 1000mm / min. In step (5), the forward and backward drive motor drives the cutter head to retreat 8mm at a speed of 1000mm / min.

Embodiment 3

[0056] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The advance and retreat drive motor drives the cutterhead to advance 18mm at a speed of 1000mm / min, and in step (5), the advance and retreat drive motor drives the cutterhead to withdraw 12mm at a speed of 1000mm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com