Manufacturing method of ultrasonic detection test piece for complex structural parts with various welding defects

A technology for welding defects and complex structures, applied in the preparation of test samples, welding equipment, manufacturing tools, etc., can solve problems such as high labor intensity and error-prone identification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

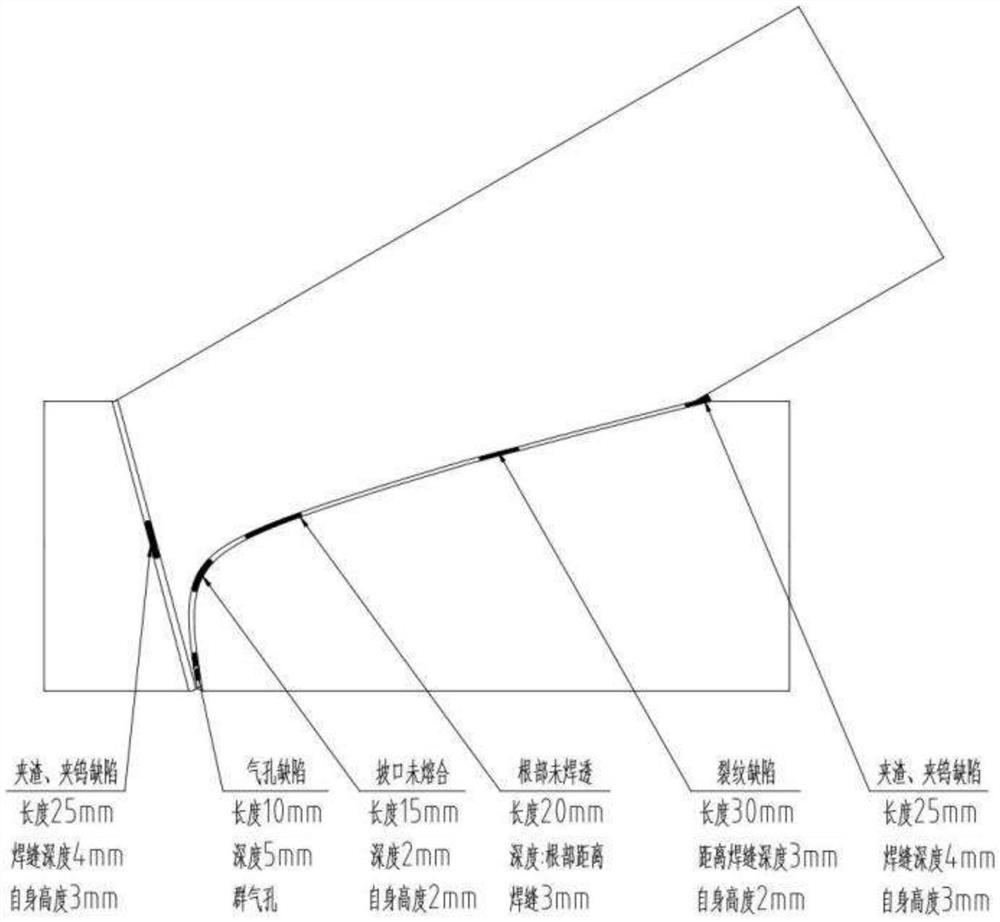

[0029] see figure 1 , the present invention provides a kind of technical scheme: comprise the following steps:

[0030] Step 1: Process one side of the groove on the welding surfaces of the two base metals to be welded respectively, and perform pretreatment;

[0031] Step 2: Aligning the unilateral grooves of the two base metals to be welded to form a complete groove;

[0032] Step 3: After the base metal to be welded forms a complete groove, argon tungsten arc welding is used for root welding;

[0033] Step 4: Then use electrode arc welding for filling welding;

[0034] Step 5: According to the preset number and position of non-fusion, use metal gas shielded welding technology to make non-fusion defects, incomplete penetration defects, porosity defects, slag inclusion defects and tungsten inclusion defects on the corresponding weld metal layer;

[0035] Step 6: Design the length and depth of the crack area and the self-deep height of the defect on the weld, and then perfor...

Embodiment 2

[0062] A method for manufacturing a steel structure test piece with welding defects, comprising the following steps:

[0063] Step 1: Welding blanking: the material is A106B steel, and the size of the test piece is Weldment 1 adopts manual processing groove, in order to prevent welding deformation, adopts symmetrical V-shaped groove, and the angle of paired groove is 45°;

[0064] Step 2: Preparation before welding: Before welding, the welding groove of the plate to be welded and the scale, rust, moisture, oil and impurities within 30 mm on both sides of the groove must be cleaned. After ensuring the cleanliness of the groove, use tungsten In polar argon arc welding, spot welding is performed at both ends of the weldment;

[0065] Step 3: Bottom welding: Tungsten argon arc welding is used for root bottom welding. The chemical composition and weight percentage of the welding wire are: C: 0.10~0.30, Si: 0.21~1.55, Mn: 2.00~3.50, Ti :0.36~0.75, N: 0.005~0.008, P≤0.008, S≤0.003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com