Thiadiazole-derivative/graphene-containing lubricating oil additive and preparation method thereof, and lubricating oil containing additive

A technology of thiadiazole derivatives and lubricating oil additives, which is applied in the field of lubricating oil to achieve the effect of improving the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

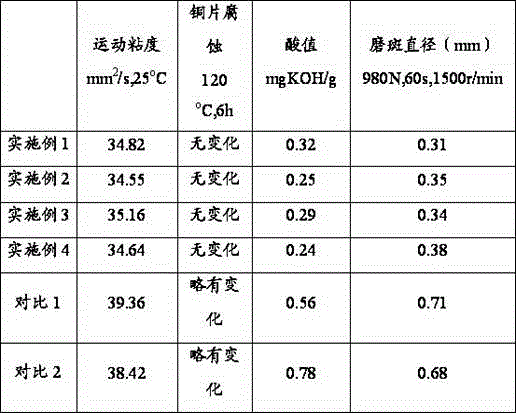

Examples

Embodiment 1

[0021] Example 1, this example provides a lubricating oil additive containing thiadiazole derivatives and graphene and a preparation method thereof, including the following substances: 1 g of thiadiazole derivatives, 0.5 g of nano-graphene, and 10 g of dodecanethiol , isopropanol 10g, 30wt% formaldehyde solution 1g, lanthanum chloride heptahydrate 0.1g, 50% sodium hydroxide solution 3g, 2,6-di-tert-butylphenol 1g.

[0022] The preparation method is as follows: first, thiadiazole derivatives and nano-graphene are added to isopropanol and dodecanethiol, ultrasonicated for 10 minutes, and then 30wt% formaldehyde solution, lanthanum chloride heptahydrate, and hydrogen with a mass fraction of 50% Sodium oxide solution, 2,6-di-tert-butylphenol, after adding, mix at 300 rpm for 5 minutes; raise the temperature to 50 degrees Celsius and keep it warm for 1 hour; after the heat preservation is completed, sonicate for 30 minutes, and cool to room temperature to get finished product.

Embodiment 2

[0023] Embodiment 2, this embodiment provides a lubricating oil additive containing thiadiazole derivatives and graphene and its preparation method, including the following substances: 1.5g of thiadiazole derivatives, 2.5g of graphene, 1-octyl thiol, 15g of isopropanol, 1g of 30wt% formaldehyde solution, 0.8g of rubidium chloride heptahydrate, 6g of 80wt% sodium hydroxide solution, 5g of 4-tert-butylphenol.

[0024] The preparation method is as follows: first, thiadiazole derivatives and graphene are added to isopropanol and 1-octyl mercaptan, ultrasonicated for 30 minutes, and then 30wt% formaldehyde solution, rubidium chloride heptahydrate, 80wt% sodium hydroxide solution, After adding 4-tert-butylphenol, mix at a speed of 600 rpm for 10 minutes; raise the temperature to 90 degrees Celsius and keep it warm for 5 hours; after the heat preservation is completed, ultrasonically for 50 minutes, and cool to room temperature to obtain the finished product.

Embodiment 3

[0025] Embodiment 3, this embodiment provides a lubricating oil additive containing thiadiazole derivatives and graphene and a preparation method thereof, including the following substances: 1 g of thiadiazole derivatives, 2 g of graphene, 5 g of n-hexanethiol, and isopropanol 10g, 30wt% formaldehyde solution 3g, samarium chloride heptahydrate 0.6g, 10wt% sodium hydroxide solution 5g, 2-amino-3,5-di-tert-butylphenol 3g.

[0026] The preparation steps are as follows: first, thiadiazole derivatives and graphene are added to isopropanol and n-hexanethiol, ultrasonicated for 20 minutes, and then 30wt% formaldehyde solution, samarium chloride heptahydrate, 10wt% sodium hydroxide solution, 2- Add amino-3,5-di-tert-butylphenol and mix at 500 rpm for 8 minutes; raise the temperature to 70 degrees Celsius and keep it warm for 3 hours; after the keep warm, ultrasonic for 40 minutes, and cool to room temperature to get the finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com