Hierarchical-pore nitrogen-doped carbon material and preparation method thereof

An aza-carbon and hierarchical pore technology, which is applied in the field of hierarchical porous aza-carbon materials and their preparation, can solve the problems of poor diffusion performance, poor adsorption selectivity, easy blockage of pores, etc., so as to achieve enhanced gas adsorption performance and enhanced adsorption. , the effect of improving the adsorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

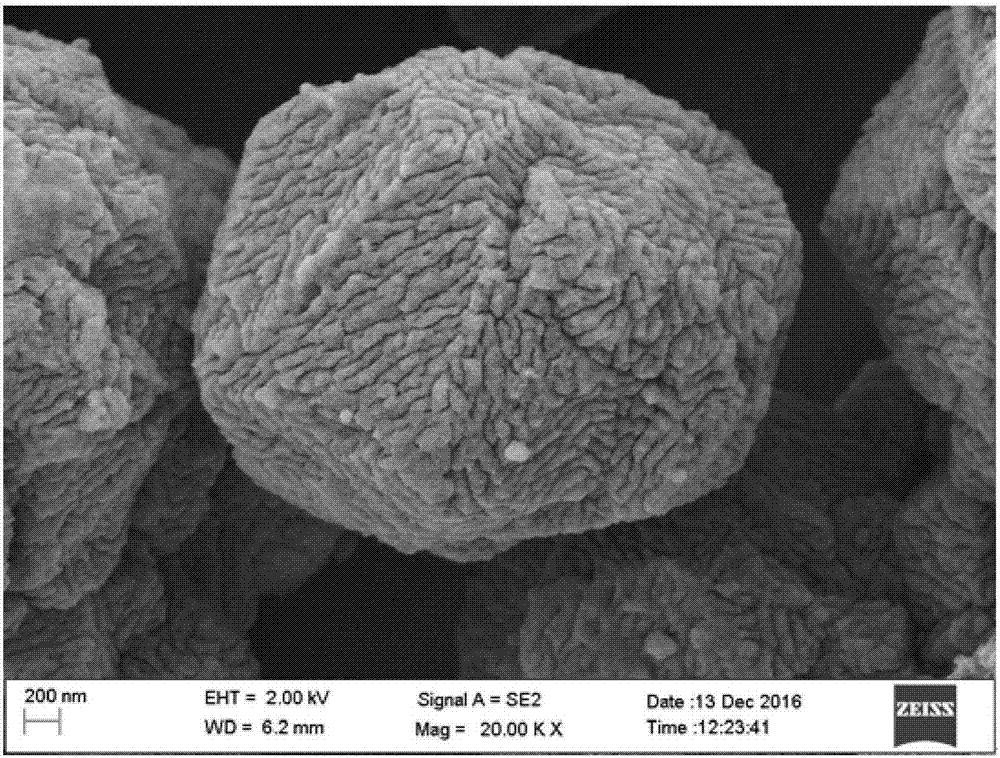

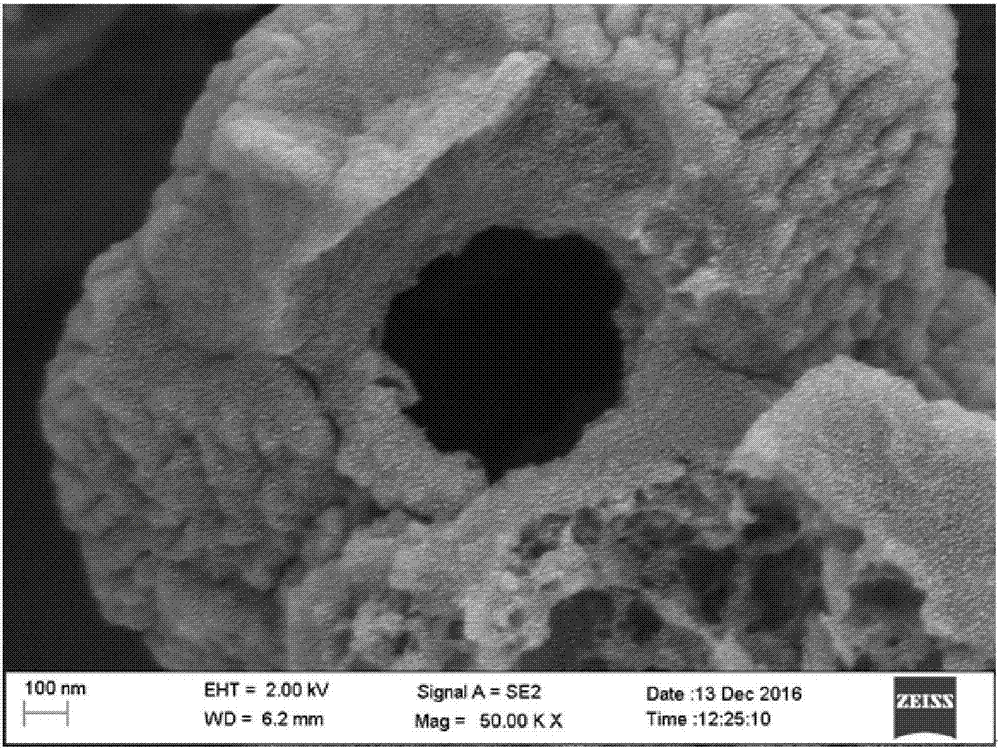

[0045] A kind of core-shell structure hierarchical porous azacarbon material, its preparation method comprises the steps:

[0046] (1) Slowly add 40 g of water dissolved with 0.7 g of zinc nitrate hexahydrate into 160 g of water dissolved with 6.5 g of 2-methylimidazole, and stir at room temperature for 2 hours to obtain ZIF-8 crystal particles containing highly dispersed metal-organic framework materials the stock solution;

[0047] (2) Take 5 g of the metal-organic framework material ZIF-8 stock solution, add 49 g of water, 2.2 g of ammonia water, 2.2 g of nonionic surfactant F127, 1.1 g of resorcinol, and 0.4 g of formaldehyde solution, stir at room temperature for 1 hour, and again Add 0.6g urea and 0.2g formaldehyde solution and stir for 0.5h;

[0048] (3) Transfer the above solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 80° C. for 24 hours. After the reaction is completed, filter, wash, and dry to obtain a metal-organic framework co...

Embodiment 2

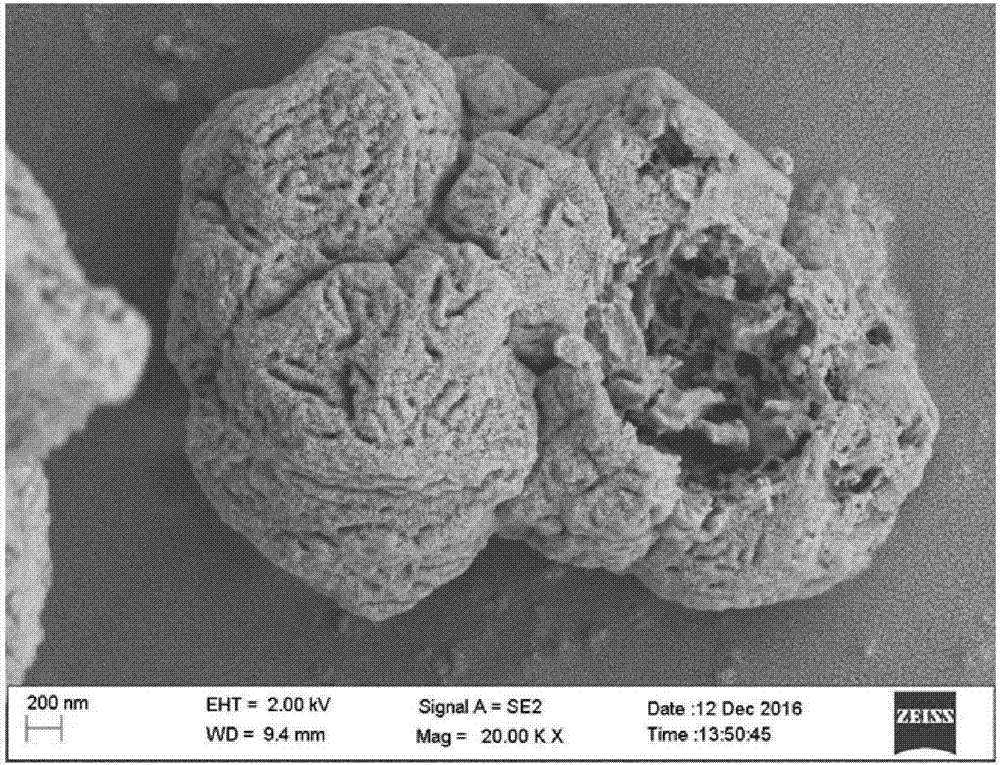

[0054] A kind of core-shell structure hierarchical porous azacarbon material, its preparation method comprises the steps:

[0055] (1) Slowly add 40 g of water dissolved with 0.7 g of zinc nitrate hexahydrate into 160 g of water dissolved with 6.5 g of 2-methylimidazole, and stir at room temperature for 2 hours to obtain ZIF-8 crystal particles containing highly dispersed metal-organic framework materials the stock solution;

[0056] (2) Take 10g of the metal-organic framework material ZIF-8 stock solution, add 44g of water, 2.2g of ammonia water, 2.2g of nonionic surfactant F127, 1.1g of phenol, and 0.4g of terephthalaldehyde solution, stir at room temperature for 1 hour, and then add 0.6g urea and 0.2g terephthalaldehyde solution, stirred for 0.5h;

[0057] (3) Transfer the above solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200° C. for 3 hours. After the reaction is completed, filter, wash, and dry to obtain a metal-organic framework ...

Embodiment 3

[0061] A kind of core-shell structure hierarchical porous azacarbon material, its preparation method comprises the steps:

[0062] (1) Slowly add 40 g of water dissolved with 0.7 g of zinc nitrate hexahydrate into 160 g of water dissolved with 6.5 g of 2-methylimidazole, and stir at room temperature for 2 hours to obtain ZIF-8 crystal particles containing highly dispersed metal-organic framework materials the stock solution;

[0063] (2) Take 20 g of the metal-organic framework material ZIF-8 stock solution, add 34 g of water, 2.2 g of sodium bicarbonate, 2.2 g of nonionic surfactant P123, 1.1 g of pyroglucinol, and 0.4 g of acetaldehyde solution, and stir for 1 h at room temperature , add 0.6g urea and 0.2g acetaldehyde solution again, stir for 0.5h;

[0064] (3) Transfer the above solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 40° C. for 72 hours. After the reaction is completed, filter, wash, and dry to obtain a metal-organic framework...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com