Ruthenium/carbon catalyst with activated carbon subjected to supercritical CO2 treatment as carrier and method for preparing catalyst

A ruthenium-carbon catalyst and activated carbon technology are applied in the field of ruthenium-carbon catalyst and its preparation, which can solve the problems of increased surface functional groups, different stability, and more adsorption of catalytically active components, and achieve the effects of mild supercritical conditions and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

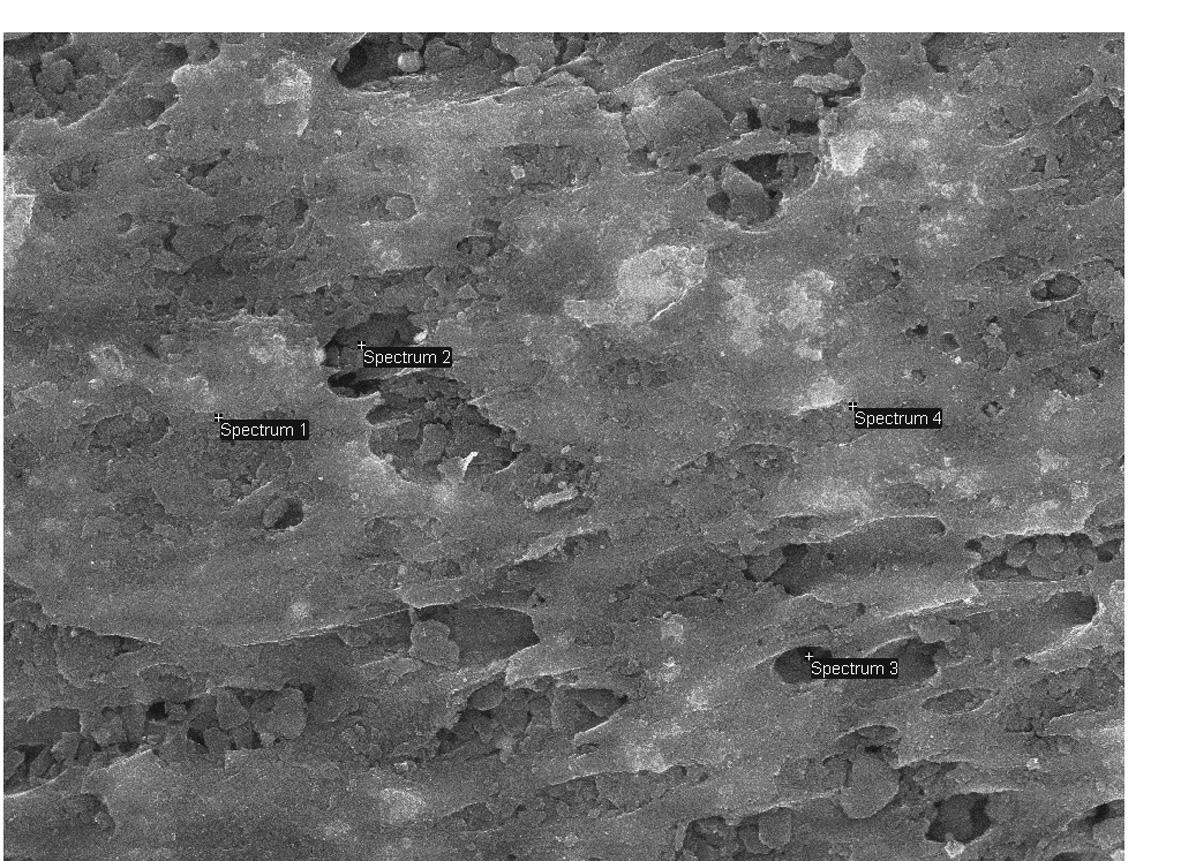

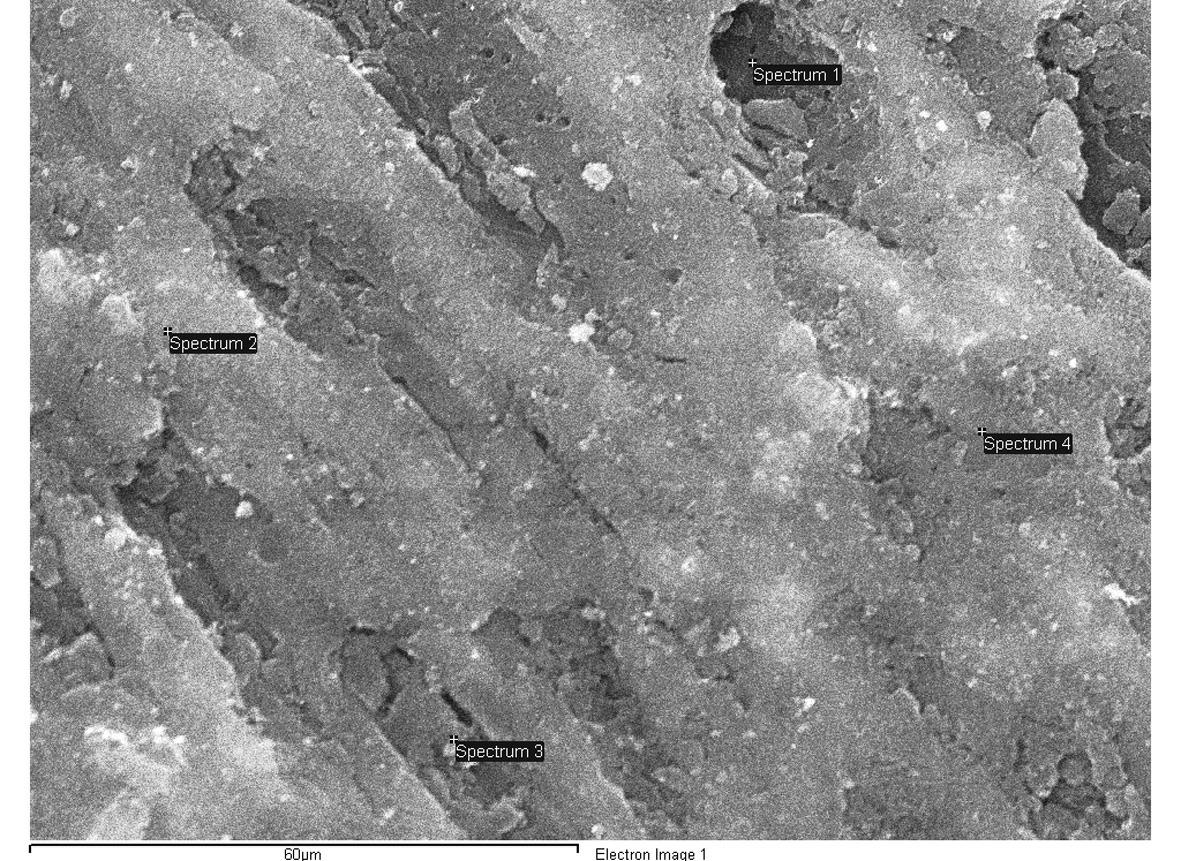

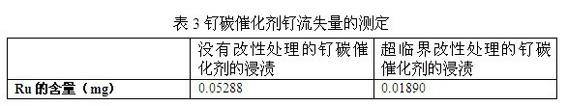

Image

Examples

example 1

[0044] Put 10.0g (40-60 mesh) activated carbon into a 150ml reactor, seal the reactor, and use a high-pressure syringe pump to pump CO 2 Fill until the pressure reaches 8.0 MPa, then use the temperature program to raise the reactor to 60 °C, maintain the supercritical condition for 2 hours, lower the temperature, release the pressure, and unload the reactor to obtain the modified activated carbon. Take 6g of the above-mentioned activated carbon, and use RuCl with a concentration of 0.05g / ml 3 (In which the ruthenium content is 37%) solution 20mL impregnated for 4 hours, then dried at 120°C, the dried sample was placed in the quartz tube of the tubular heating furnace, reduced with hydrogen, reduced at 200°C for 2h, 300h°C for 1h, stop heating, When continuing to cool to room temperature through hydrogen, the ruthenium carbon catalyst sample was obtained. The activity assay result was 46.41 mmol·min -1 g -1 Ru.

example 2

[0046] Put 10.0g (40-60 mesh) activated carbon into a 150ml reactor, seal the reactor, and use a high-pressure syringe pump to pump CO 2 Fill until the pressure reaches 8.0 MPa, then use the temperature program to raise the reactor to 80 °C, maintain the supercritical condition for 2 hours, lower the temperature, release the pressure, and unload the reactor to obtain the modified activated carbon. Take 6g of the above-mentioned activated carbon, and use RuCl with a concentration of 0.05g / ml 3 Immerse 20mL of aqueous solution (the ruthenium content is the same as Example 1) for 4 hours, then dry at 120°C, put the dried sample into the quartz tube of the tubular heating furnace, reduce with hydrogen, reduce at 200°C for 2h, and at 300h°C for 1h, stop heating, When continuing to cool to room temperature through hydrogen, the ruthenium carbon catalyst sample was obtained. Activity assay result 49.92 mmol·min -1 g -1 Ru.

example 3

[0048] Put 10.0g (40-60 mesh) activated carbon into a 150ml reactor, seal the reactor, and use a high-pressure syringe pump to pump CO 2 Fill until the pressure reaches 8.0 MPa, then use the temperature program to raise the reactor to 100 °C, maintain the supercritical condition for 2 hours, lower the temperature, release the pressure, and unload the reactor to obtain the modified activated carbon. Take 6g of the above-mentioned activated carbon, and use RuCl with a concentration of 0.05g / ml 3 Immerse in 20mL of aqueous solution (the content of ruthenium is the same as in Example 1) for 4 hours, then dry at 120°C, put the dried sample into the quartz tube of the tubular heating furnace, reduce it with hydrogen, reduce at 200°C for 2h, and at 300h°C for 1h, stop heating, When continuing to cool to room temperature through hydrogen, the ruthenium carbon catalyst sample was obtained. Activity assay result 47.78 mmol·min -1 g -1 Ru.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com