Aluminum modified straw biomass charcoal as well as preparation method and application thereof on removing arsenic in water body

A biomass carbon, aluminum modification technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as weak anion adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

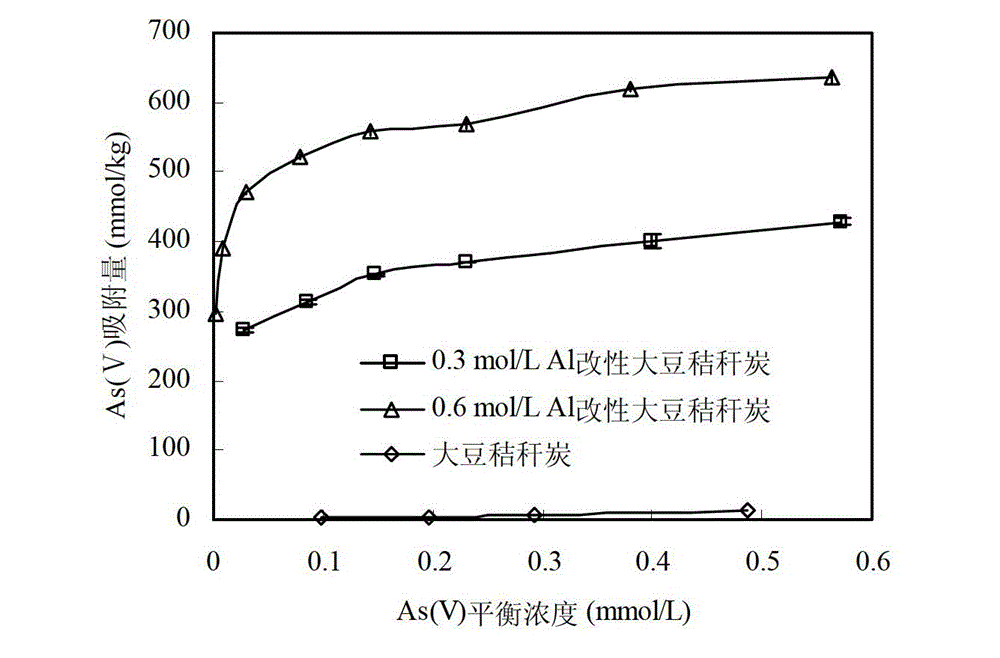

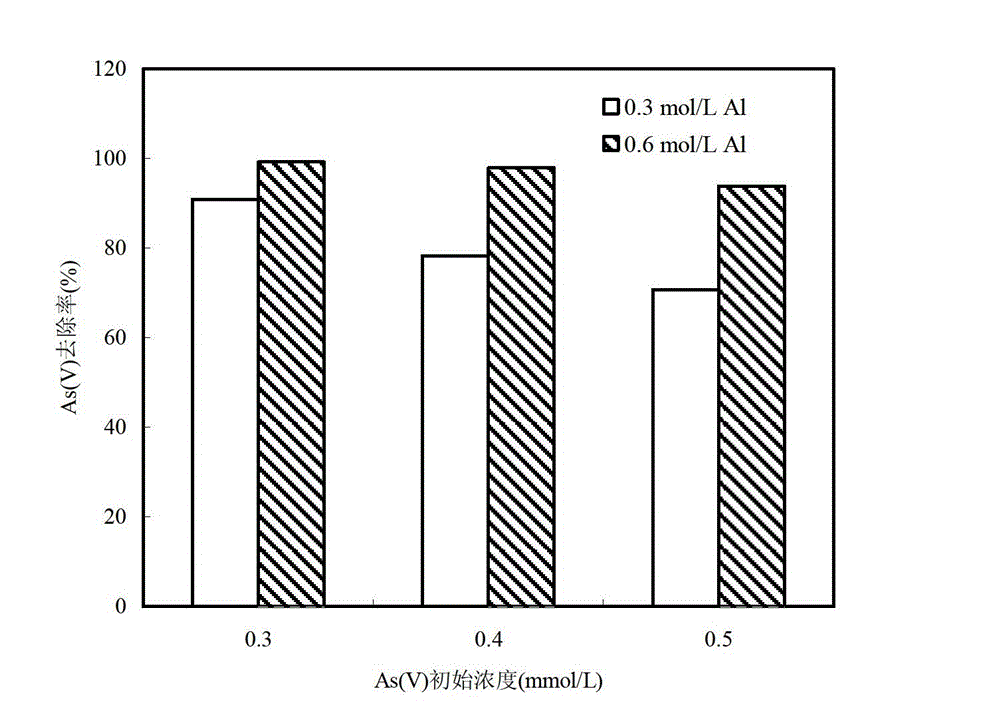

[0027] Comparison of As(V) adsorption capacity and removal effect of biochar modified with different initial concentrations of aluminum solutions.

[0028] Biochar was prepared from air-dried soybean straw under anaerobic conditions of 350 °C. The specific steps are as follows: the soybean stalks are air-dried, ground and passed through a 1mm sieve. A ceramic crucible filled with soybean straw was placed in a muffle furnace, and the temperature was raised to 350°C at a rate of 20°C / min. After maintaining for 4 hours, the power was turned off, and the soybean straw charcoal was taken out after the temperature of the muffle furnace dropped to room temperature. Add 20 g of soybean straw charcoal to 200 mL of AlCl with an initial concentration of 0.3 mol / L under magnetic stirring conditions 3 In the solution, the pH was adjusted to 7.0 with 0.5 mol / L NaOH and maintained for 2 hours. Place in a constant temperature incubator at 25°C for 48 hours, then centrifuge, wash once with d...

Embodiment 2

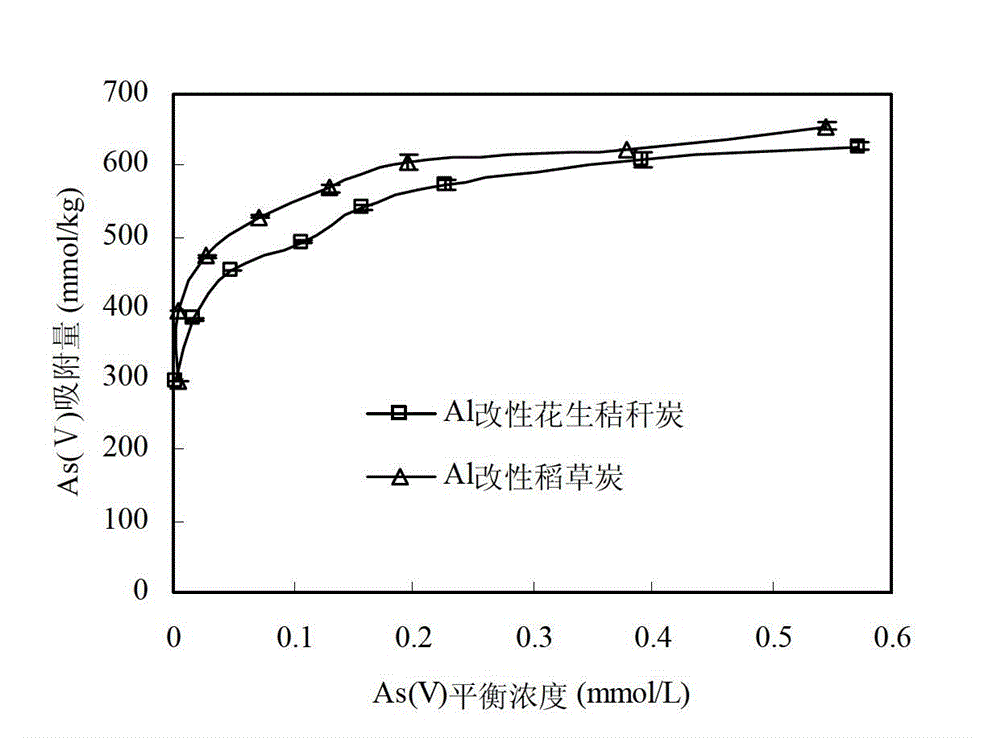

[0032] Comparison of the adsorption capacity and removal effect of aluminum-modified peanut straw charcoal and rice straw charcoal on As(V).

[0033] According to the method in Example 1, the peanut straw charcoal and rice straw charcoal prepared at 350°C were reacted with 0.6 mol / L aluminum solution to prepare aluminum-modified biochar. Then according to the method in Example 1, the adsorption capacity and removal rate of Al-modified biochar to As(V) were studied. image 3 is the adsorption capacity of two kinds of aluminum-modified biochars for As(V). Similar to soybean straw charcoal modified with 0.6 mol / L aluminum solution, aluminum-modified rice straw charcoal and peanut straw charcoal also have high adsorption capacity for As(V), the maximum adsorption capacity can reach 655 and 627mmol / kg, respectively. Figure 4 is the removal rate of As(V) by two kinds of aluminum-modified straw biochars. When the initial concentrations of As(V) were 0.3, 0.4 and 0.5 mmol / L, the re...

Embodiment 3

[0036] Adsorption capacity of Al-modified biochar for As(V) at different pH.

[0037] Prepare an As(V) solution with an initial concentration of 0.8 mmol / L, adjust the pH of the solution to a range of 3.5 to 6.5 with HCl and NaOH, and then study the effect of aluminum-modified biochar on As(V) according to the method in Example 1. adsorption capacity. Figure 5 is the adsorption capacity of three kinds of Al-modified biochars for As(V) at different pH. The adsorption capacity of Al-modified biochar on As(V) decreased with the increase of system pH, but the Al-modified biochar had higher adsorption capacity on As(V) in the acidic range. Since the arsenic-containing wastewater produced by metal ore mining and smelting is mostly acidic and strongly acidic, this provides favorable conditions for the adsorption and removal of As(V) by aluminum-modified biochar. However, when the pH of the arsenic-containing wastewater is lower than 4.0, it is necessary to add an appropriate amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com