Mannich base acidifying corrosion inhibitor and preparation method thereof

A Mannich base, acidizing corrosion inhibitor technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of amino hydroxy compounds, etc., can solve the problems of poor solubility, poor compactness of protective film, easy volatility, etc. The adsorption strength and compactness, the corrosion inhibition effect is obviously improved, and the acidification cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of the Mannich base acidification slow-release agent of the present invention is characterized in that, pour dodecyl dimethyl tertiary amine, paraformaldehyde and aromatic ketone into the reaction kettle according to the material ratio, add ethanol as a solvent, Then slowly add hydrochloric acid to adjust the pH value of the reaction solution, then slowly raise the temperature to 80±5°C, keep the temperature at reflux for 5 to 7 hours, and obtain the Mannich base:

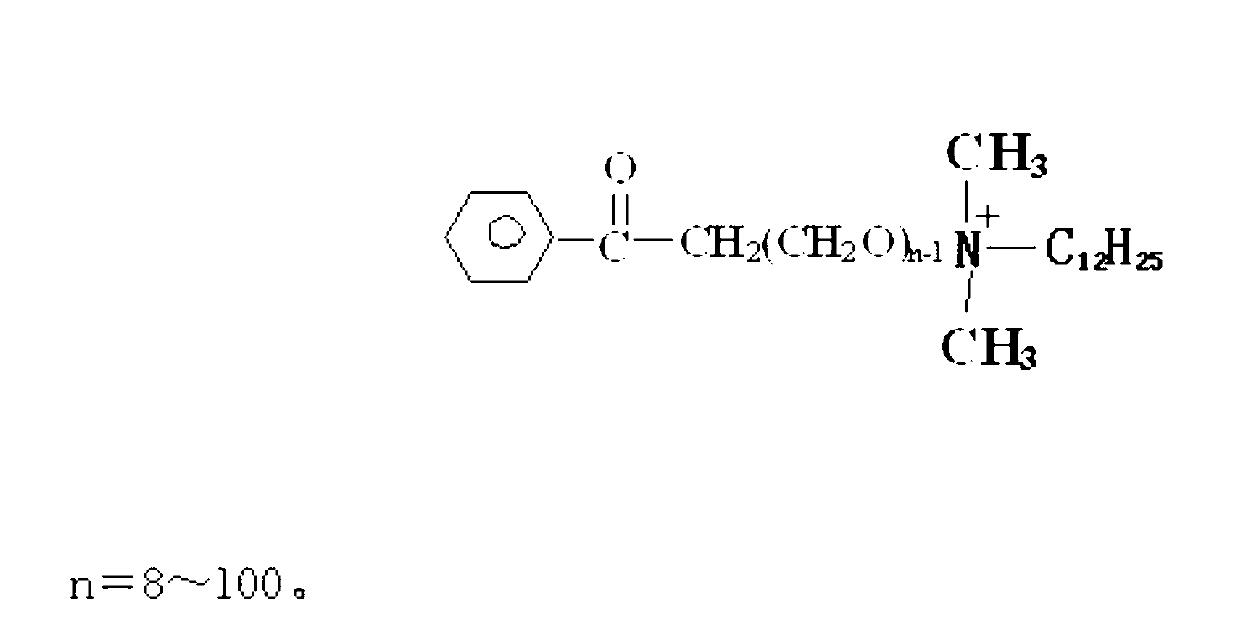

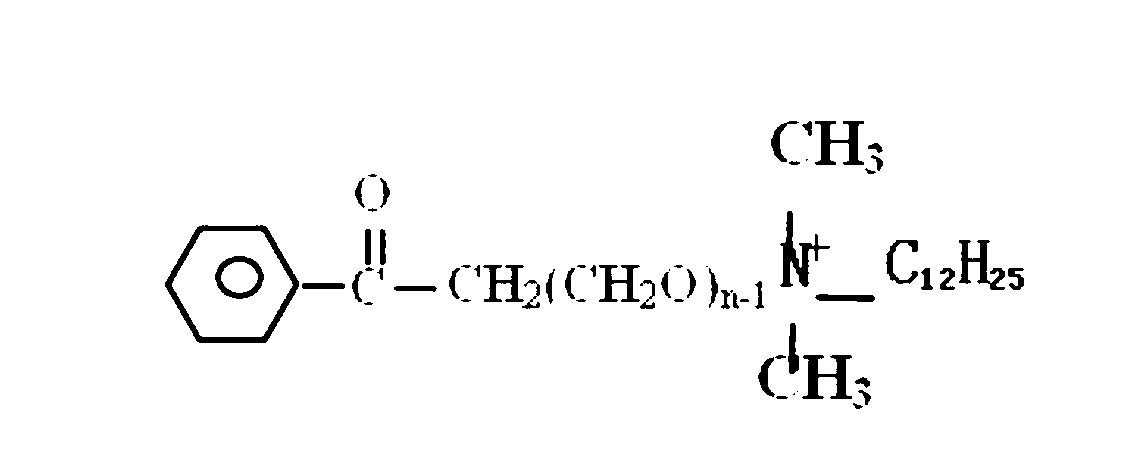

[0024]

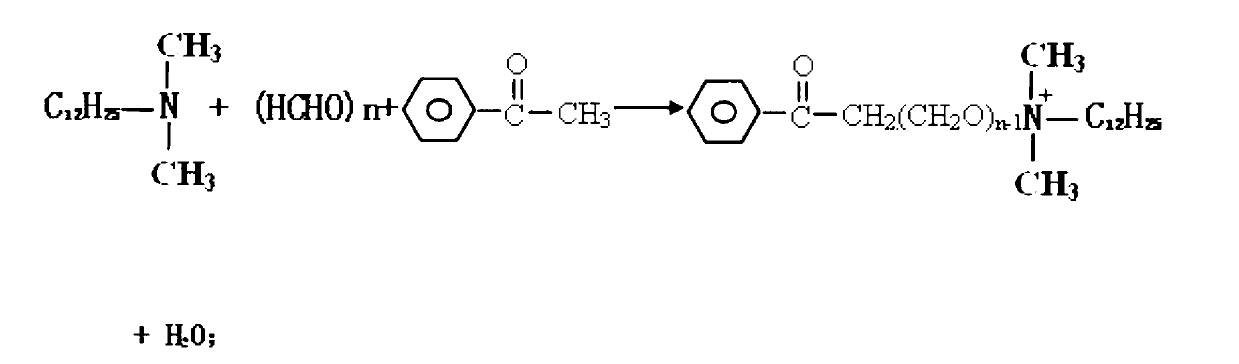

[0025] Its reaction equation is as follows:

[0026]

[0027] The Mannich base ( )

[0028] It is compounded with acetic acid, propynyl alcohol and potassium iodide at a weight ratio of 6:2.5:0.5:1 to obtain a finished Mannich base acidifying corrosion inhibitor; in the formula: n=8~100.

[0029] The preparation method of the Mannich base acidified sustained-release agent of the present invention, wherein, the paraformaldehyde is a linear polymer of formaldehyde, its ...

Embodiment

[0031] 1. Raw materials

[0032] (1) Paraformaldehyde

[0033] Paraformaldehyde, also known as paraformaldehyde, solid formaldehyde, or polymerized formaldehyde, is a linear polymer of formaldehyde, with a structural formula of (HCHO)n, a molecular weight of (30)n, and n=8 to 100.

[0034] (2) Aromatic ketones

[0035] This embodiment selects acetophenone molecular formula as C 8 h 8 o

[0036] (3) Dodecyldimethyl tertiary amine

[0037] Molecular formula: C 12 h 25 N(CH 3 ) 2

[0038] 2. Ratio of materials (parts by weight)

[0039] Acetophenone: dodecyldimethyl tertiary amine: paraformaldehyde = 1:1:1

[0040] 3. Synthesis conditions

[0041] Pour dodecyldimethyl tertiary amine, paraformaldehyde and acetophenone into the reaction kettle according to the material ratio, add ethanol with 15% of the total weight of the material as a solvent, slowly add 43% of the total weight of hydrochloric acid, hydrochloric acid The concentration is 15%, adjust the pH value, slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com