Method and system for preparing high purity taurine and salt

A technology of taurine and taurine, which is applied in chemical instruments and methods, preparation of sulfonic acid, preparation of sulfonate, etc., can solve the problems of purity of crude taurine and sodium sulfate, low purity of separated products, Solve problems such as complicated separation process, and achieve the effects of easy automation, good crystal form and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

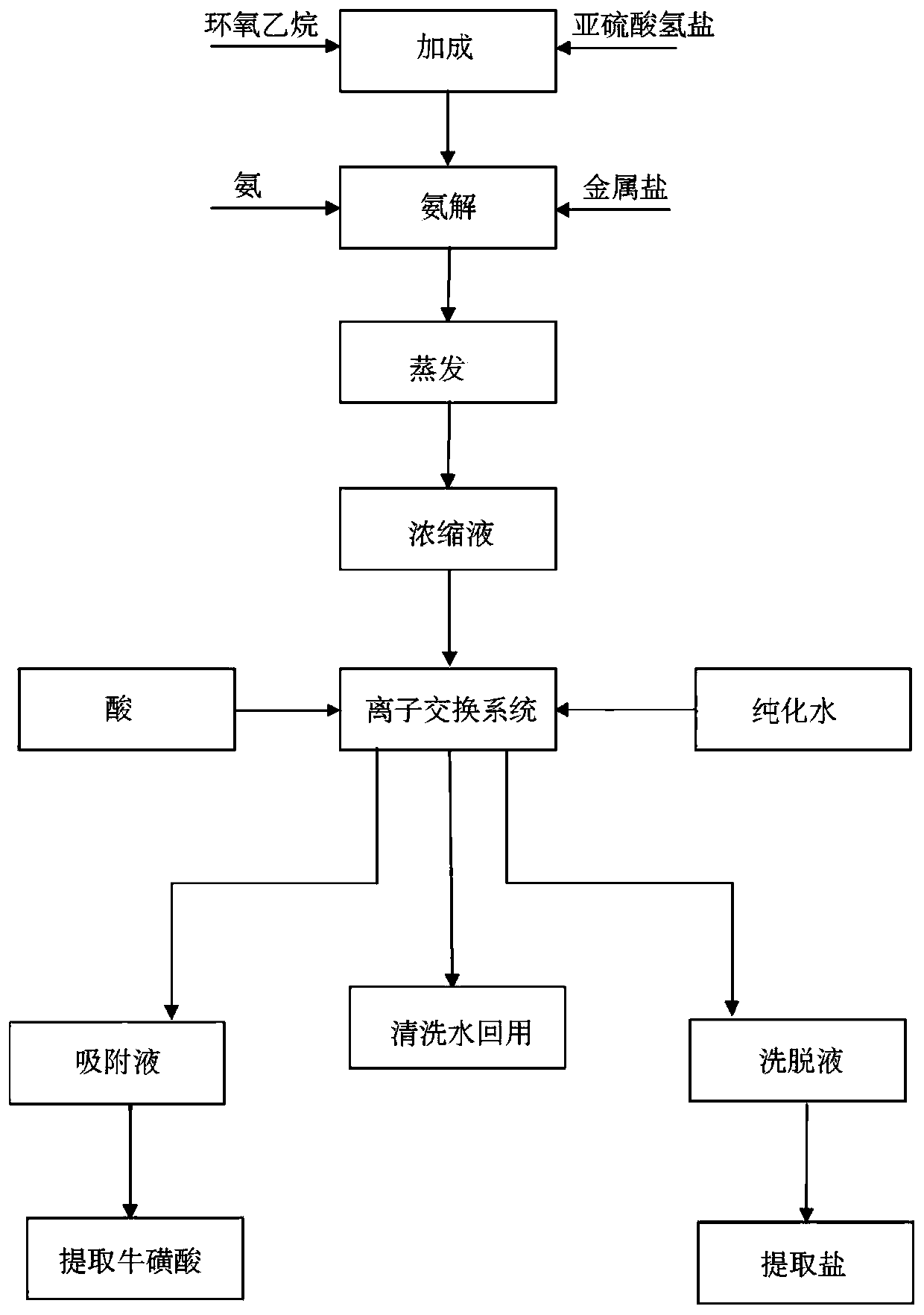

Method used

Image

Examples

Embodiment 1

[0072] Present embodiment shows the preparation process of ammonia solution.

[0073] Preparation of sodium isethionate: mix sodium bisulfite solution with ethylene oxide at a ratio of sodium bisulfite to ethylene oxide molar ratio of 1.05:1, at pH 6.2-6.8, temperature 60-65 Under the condition of ℃, the sodium isethionate can be prepared.

[0074] Preparation of ammonia solution: react sodium isethionate, sodium hydroxide and ammonia water at 255°C and 10-18MPa for 45 minutes (minutes), after the reaction is completed, drive out ammonia gas and recover it, and concentrate to obtain Ammonolysis reaction concentrate.

Embodiment 2

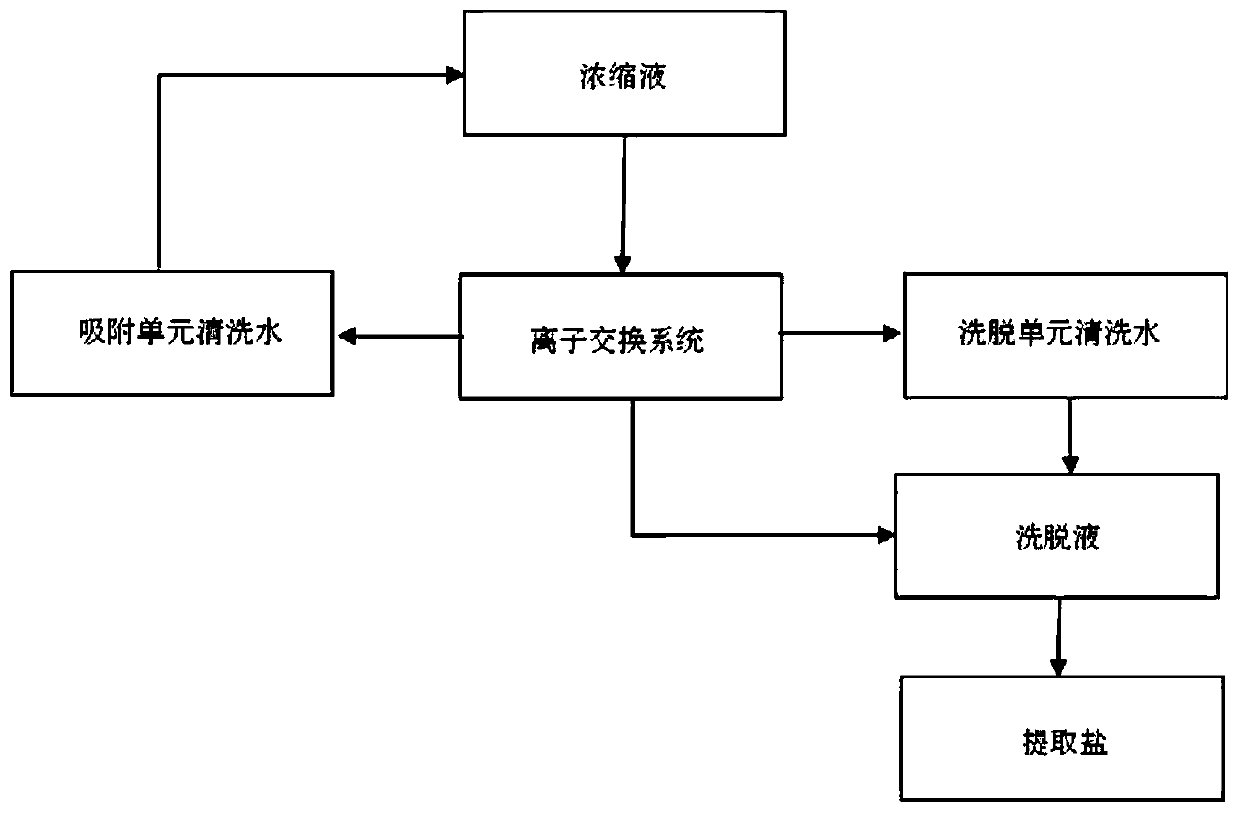

[0076] This example shows that the ion exchange system adsorbs sodium ions to achieve separation into two material solution systems of taurine and sodium sulfate.

[0077] The ammonolysis concentrated solution was prepared as 18L of a solution with a taurine content of 20%. Prepare 12L of sulfuric acid solution with a concentration of 15%. In a small ion exchange system equipped with a resin capable of adsorbing sodium ions, the prepared taurine solution is pumped into the system, and the pH of the collected absorption solution is controlled to be 7-8, and the sodium ion content in the adsorption solution is 0.05%- 1%, a total of 22 L was collected, the content of taurine was 16%, and the content of sodium isethionate was 1.5%. Clean the system with purified water, reuse the cleaning water of the adsorption unit into the material of the concentrate, and wash until the taurine content cannot be detected. Pump 15% sulfuric acid solution into the cleaned system, control the pH ...

Embodiment 3

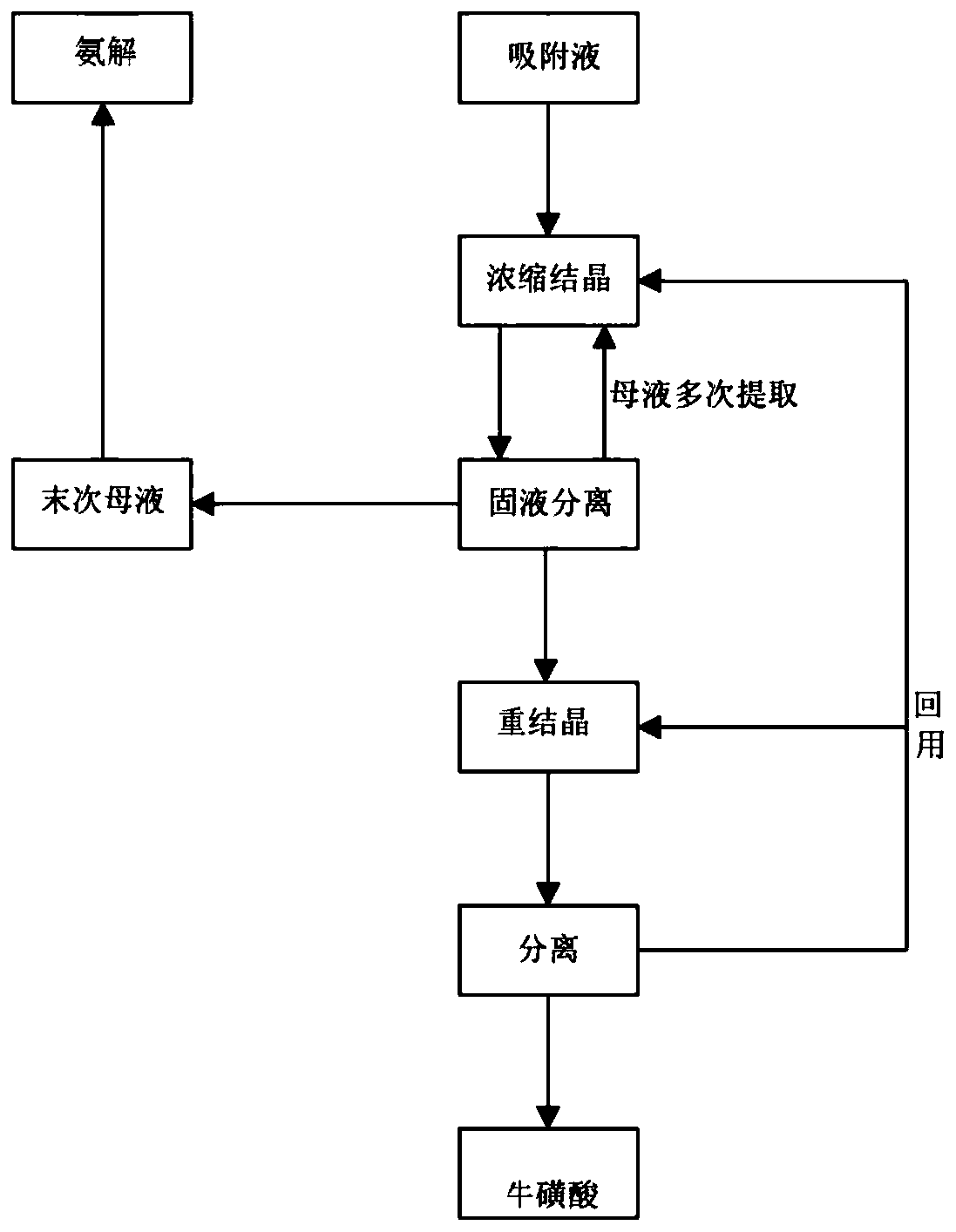

[0080] This embodiment shows that the adsorption solution and eluent collected in Example 2 are respectively concentrated and extracted.

[0081] (1) Extraction of adsorption liquid: get 3L of adsorption liquid, concentrate until the taurine content is 33%, cool to 15 ℃ and centrifuge to obtain the crude product content of taurine 95.5% (g / g), moisture content 3.5% (g / g) g). The moisture content is 98.96% (g / g), and the purity is very high. After the taurine is extracted, the taurine content in the mother liquor is 10%, the sodium isethionate content is 4.7%, and the sulfate content is less than <10PPm.

[0082] (2) Extraction of eluent: Take 3L of the adsorption solution, concentrate at 95°C for 6 times of crystallization, and centrifuge to obtain a sodium sulfate content of 97.5% (g / g) and a water content of 2.0% (g / g). The moisture content is 99.49% (g / g), and the purity is very high. The taurine content in the mother liquor is less than 1ppb, the hydroxysodium content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com